Energy-saving anti-freezing power distribution cabinet

An energy-saving technology for power distribution cabinets, which is applied in the field of energy-saving antifreeze power distribution cabinets. It can solve the problems of high airtightness of the interlayer structure of the box body, cracking of the cabinet body, danger, etc., and solve the problems of abnormal use and constant temperature. , good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with specific embodiments. The exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not as a limitation to the present invention.

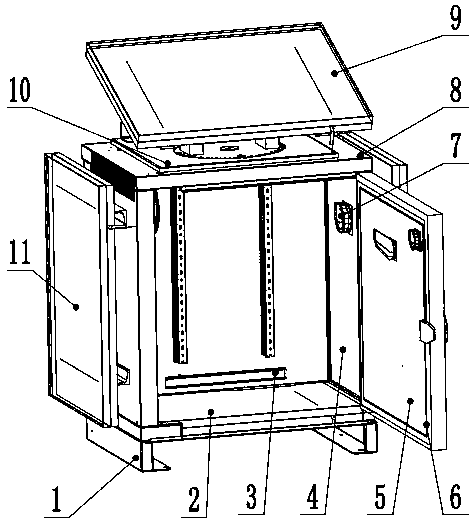

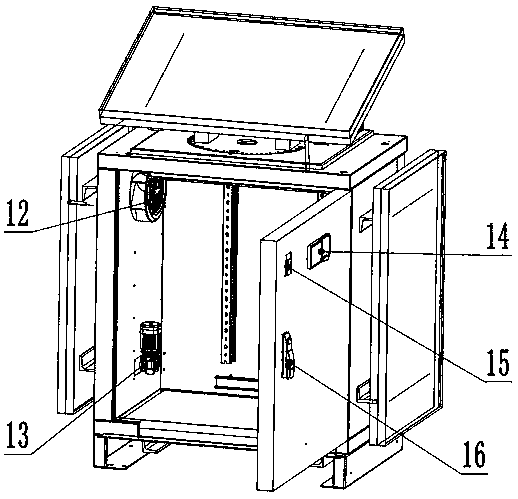

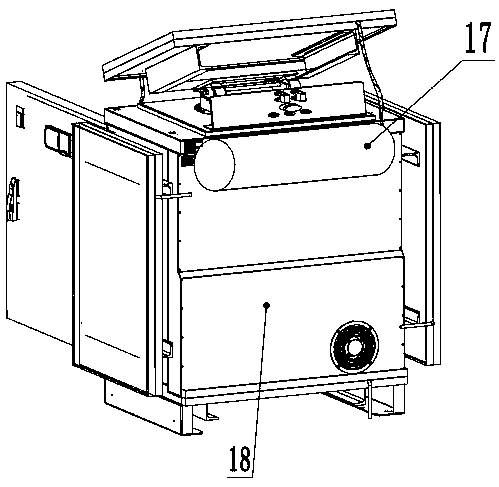

[0023] Example: such as figure 1 , 2 , 3, 4 shows an energy-saving antifreeze power distribution cabinet, including base 1, box bottom plate 2, slide rail 3, box side plate 4, door 5, sealing strip 6, temperature controller 7, box top plate 8. Top solar collector 9, sun tracking device 10, side solar collector 11, heat circulation fan 12, circulation pump 13, embedded control panel 14, temperature control switch 15, door lock 16, water tank 17, box Body back plate 18, heat circulation pipeline 19, insulation cotton 20, base 1 is a sheet metal frame structure, fixedly installed on the ground, box bottom plate 2, box side plate 4, box top plate 8, box back plate 18 Assembled together into an open box, its bottom sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com