Fabricated replaceable two-stage buckling-restrained energy dissipation supporting component

A technology for preventing buckling, energy dissipation, and supporting components. It is applied to building components, earthquake-proof, protective buildings/shelters, etc., and can solve problems such as damage, inconvenient post-earthquake repair, and damage to non-structural components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in detail below with reference to specific embodiments.

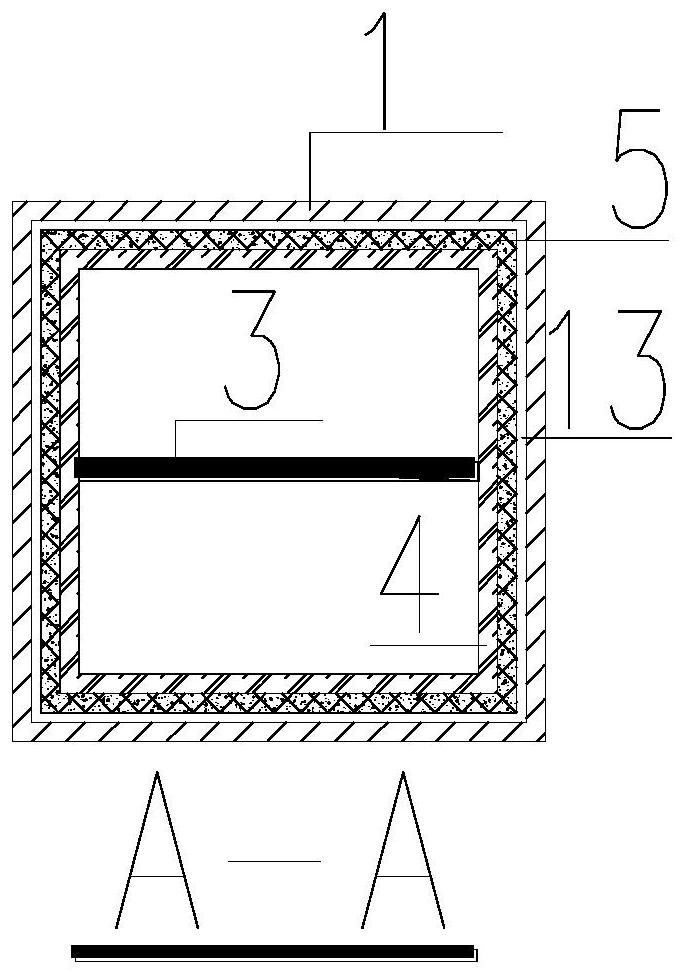

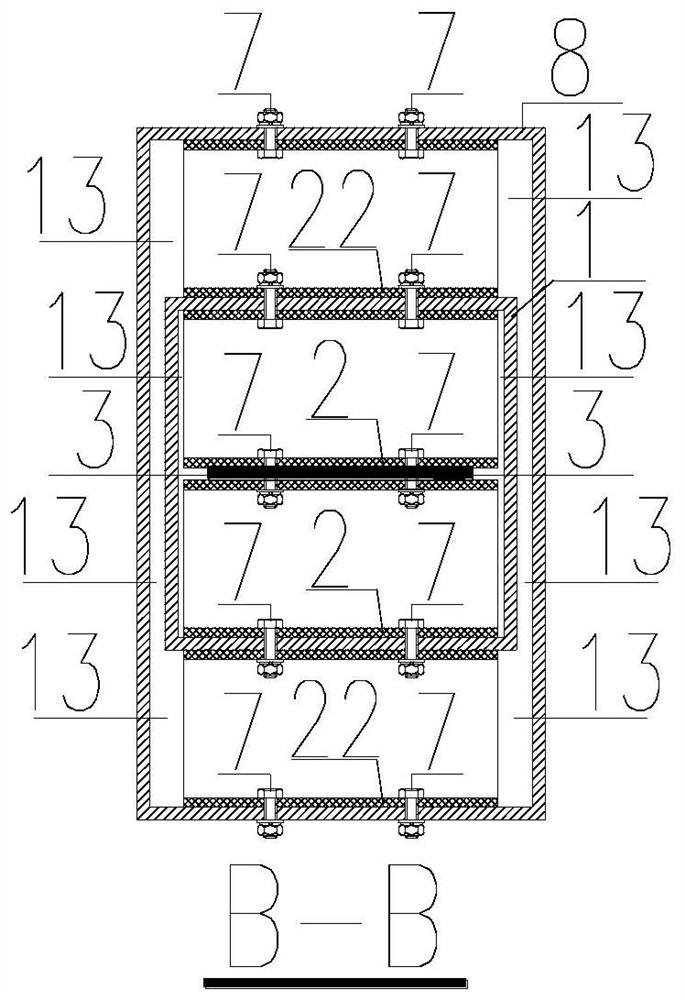

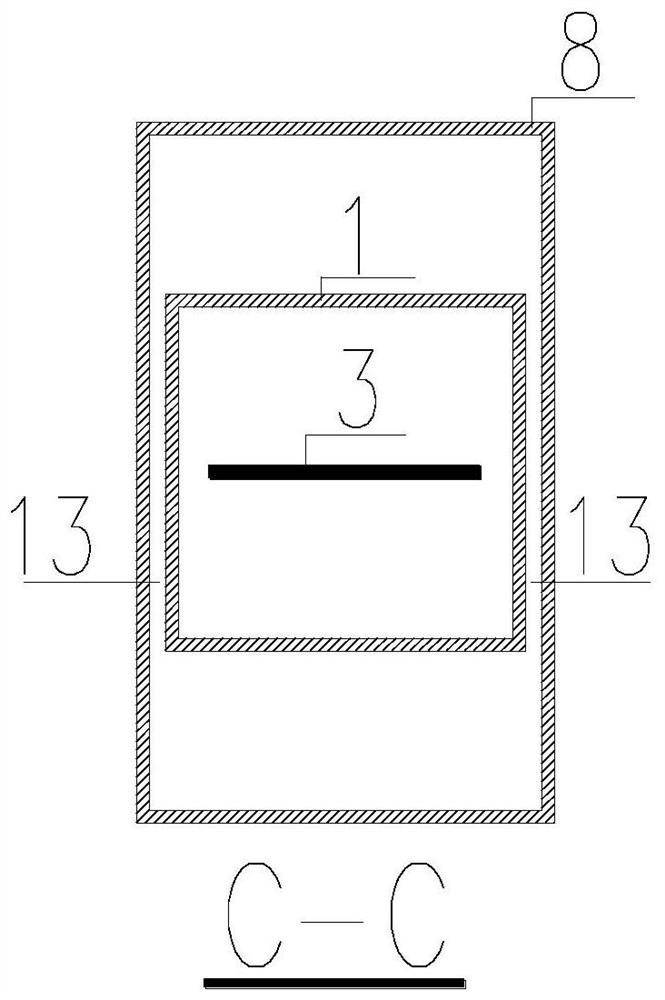

[0046] like Figure 1-15 As shown in the figure, a prefabricated and replaceable two-stage anti-buckling energy-dissipating support member includes a two-stage anti-buckling energy-dissipation structure; The core material steel plate 3, the steel pipe plug 4, the lubricating coating 5, and the connecting end plate 12; The interior of the steel pipe 1 is divided into upper and lower spaces. Preferably, the core steel plate 3 is located at the center of the inner steel pipe 1, and the interior of the square steel pipe 1 is divided into two equal spaces, upper and lower, and the first stage is installed in the upper and lower spaces. The oval steel pipe 2, the first-level oval steel pipe 2 is composed of two opposite circular arc steel plates and two opposite straight steel plates. Fixed parallel to the axis of the inner steel pipe 1, the two opposite straight steel plates o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com