Substrate for in-situ measurement of stress combined with finite element in laser net shaping

A net-shaping, finite element technology, applied in the field of in-situ monitoring of additive manufacturing, can solve the problems of increasing the time cost, high economic cost, and increased cost of the laser net-shaping process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

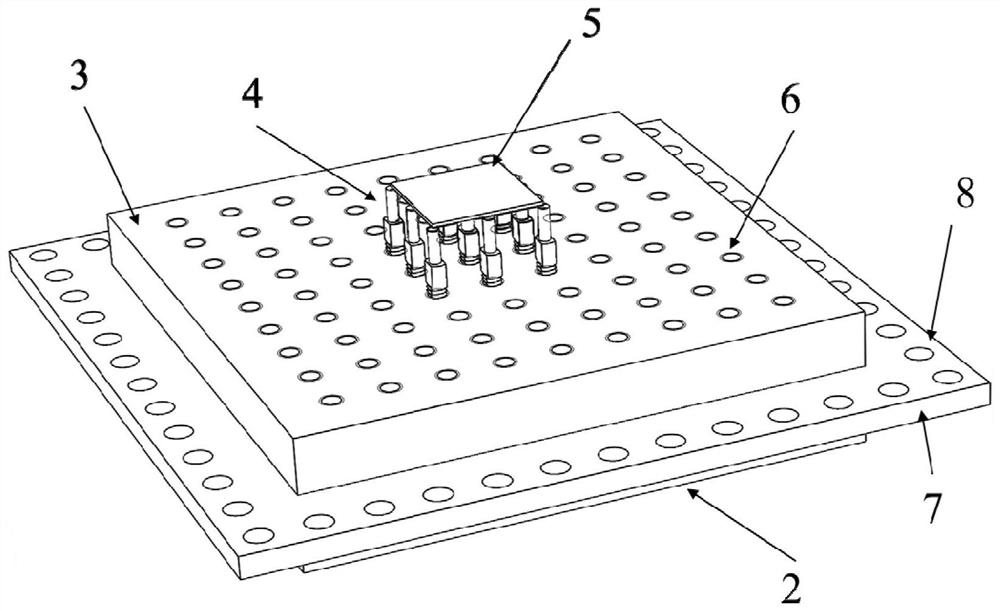

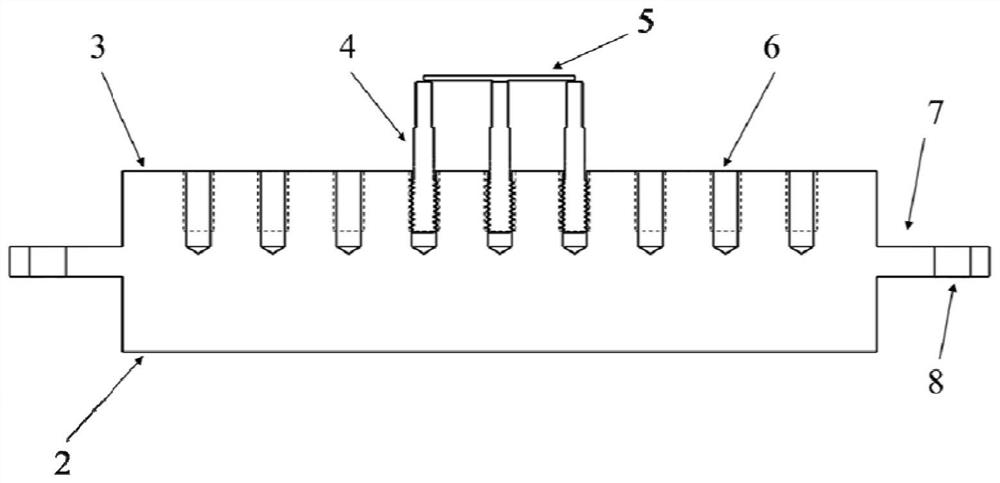

[0015] The substrate proposed by the present invention for in-situ measurement of stress in combination with finite elements in laser net shaping has a structure such as figure 1 As shown, it includes a substrate body 1, a specular reflection sheet 5 and a reflection sheet positioning bolt 4; substrate fixing wings 7 are processed around the substrate body 1, and substrate positioning holes 8 are opened on the substrate fixing wings 7; the substrate body 1 The upper surface is the manufacturing surface 2, the lower surface of the substrate body 1 is the measuring surface 3, and the measuring surface 3 is processed with evenly distributed measuring surface thread lattice holes 6, and the reflector positioning bolts 4 are connected with the measuring surface thread lattice holes 6 Cooperating with each other, the specular reflection sheet 5 is fixed on the end of the positioning bolt 4 of the reflection sheet.

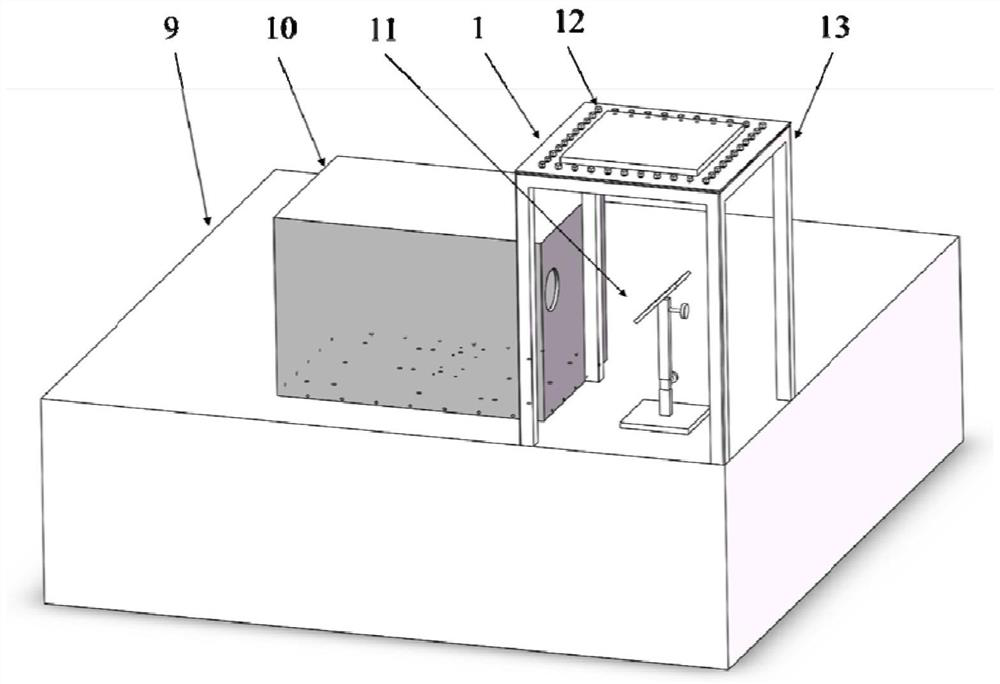

[0016] Below in conjunction with accompanying drawing, introduce c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com