An intelligent building spraying machine

A technology of intelligent building and spraying machine, which is applied in the direction of construction and building construction, can solve the problem of increasing the labor load of workers, and achieve the effect of increasing the labor load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

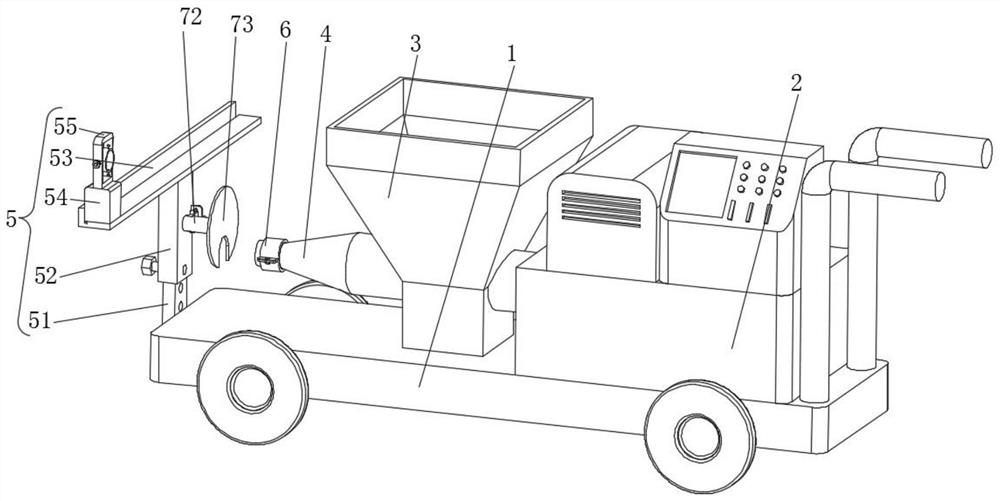

[0030] Example 1, such as Figure 1-8 As shown, the present invention provides an intelligent building spraying machine, including a base plate 1 and an adjustment structure 5, the top of the base plate 1 is fixedly connected with a connection cabinet 2, and the end of the connection cabinet 2 away from the base plate 1 is fixedly connected with a controller and a motor box. The top of the bottom plate 1 is fixedly connected with the material storage frame 3, and the inside of the material storage frame 3 is inserted with a connecting pipe 4. The end of the connecting pipe 4 close to the controller communicates with the connection cabinet 2, and the end of the bottom plate 1 away from the connection cabinet 2 is provided with an adjustment Structure 5.

[0031] Let's talk about the specific settings and effects of its adjusting structure 5, fixing structure 6 and auxiliary structure 7 in detail below.

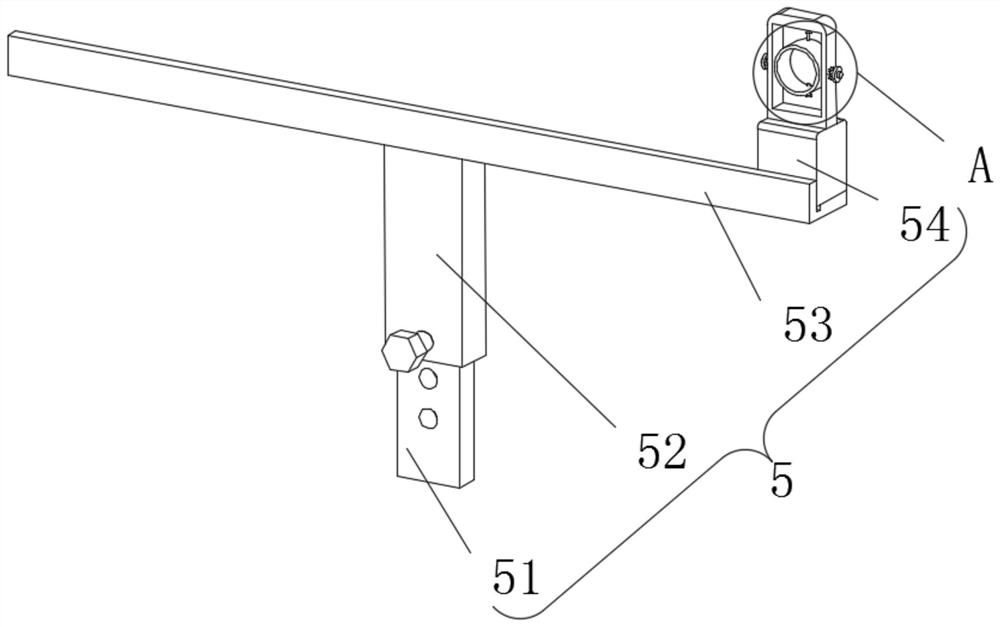

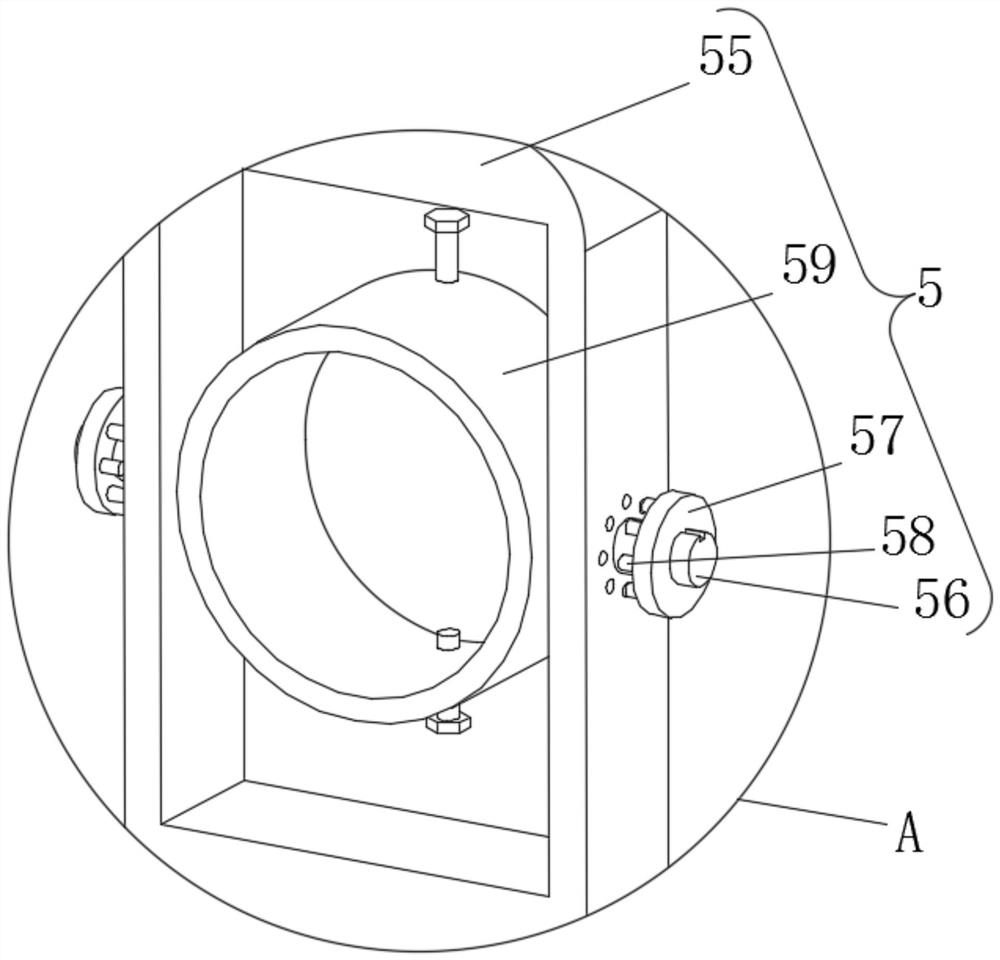

[0032] like figure 1 and Figure 4As shown, the adjustment structure 5 ...

Embodiment 2

[0036] Embodiment 2, on the basis of embodiment 1, as figure 1 and image 3 As shown, the sliding frame 52 is provided with an auxiliary structure 7 near one end of the connecting pipe 4, the auxiliary structure 7 includes a fixed column 71, the surface of the fixed column 71 is fixedly connected with the sliding frame 52, and the surface of the fixed column 71 is slidably connected with a sleeve 72, The end of the sleeve 72 away from the sliding frame 52 is fixedly connected to the limit plate 73, and the end of the sliding frame 52 close to the fixed column 71 is fixedly connected to a rectangular plate 74. A sliding rod 75 is inserted inside the rectangular plate 74, and the surface of the sliding rod 75 is fixed. A long plate 76 is connected, and the end of the slide rod 75 away from the fixed column 71 is fixedly connected with a sphere 77. First, the middle part of the nozzle is wound on the sleeve 72, and then the two ends of the nozzle are connected to the connecting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com