Binocular vision measurement method for coal flow of belt conveyor based on deep transfer learning

A technology of binocular vision measurement and belt conveyor, applied in the direction of measuring devices, optical devices, image analysis, etc., can solve the failure of stereoscopic matching of coal material images, affecting the operating efficiency of the system, and the calculation error of binocular vision measurement of coal flow and other issues to achieve real-time speed optimization and energy saving, ensure computing efficiency, and improve visibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0100] The present invention will be further described below.

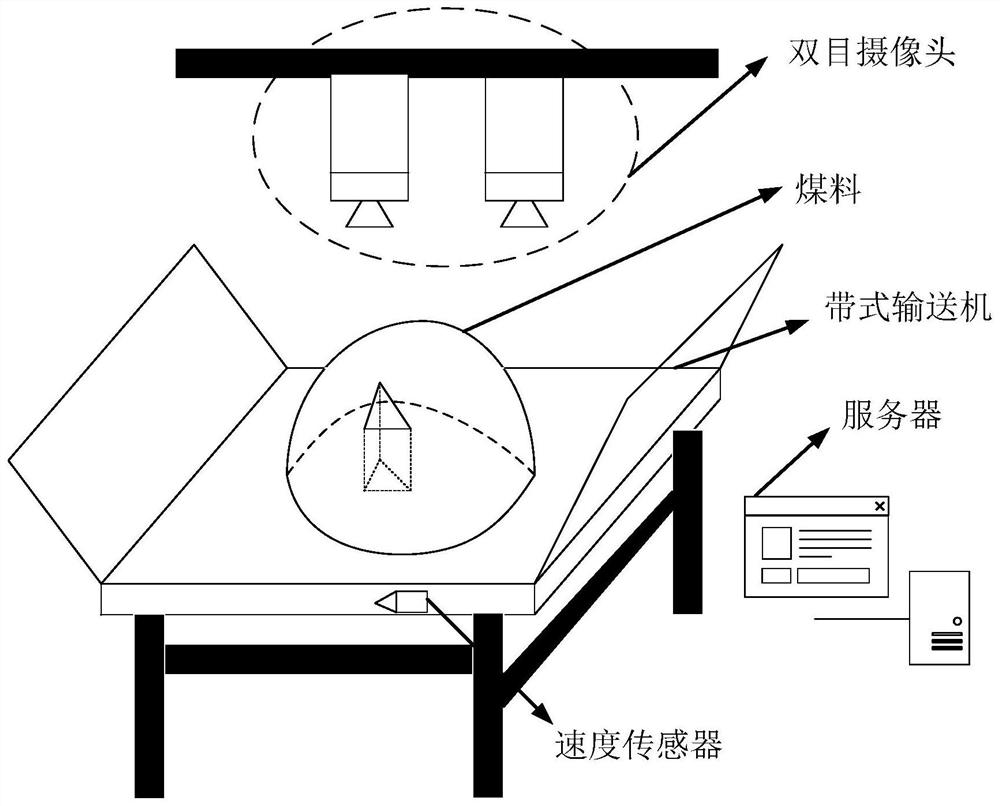

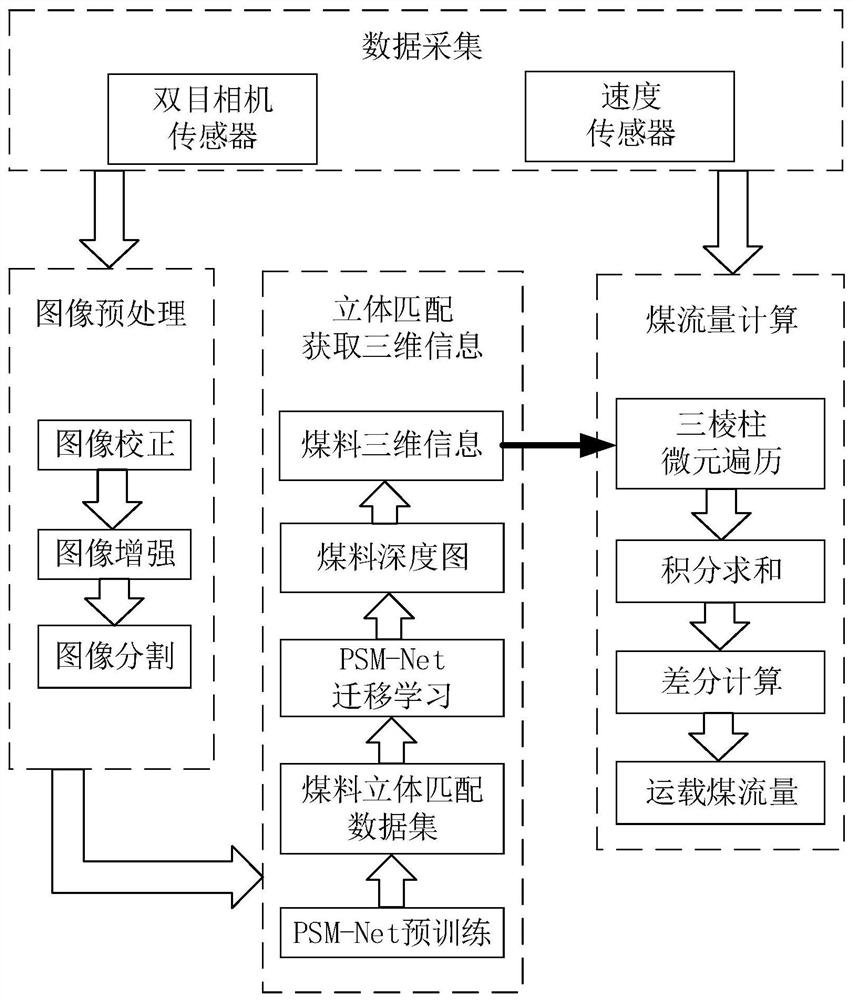

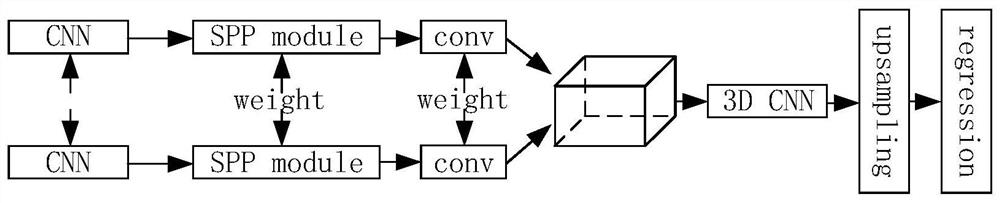

[0101] Such as Figure 1 to Figure 4 As shown, the intelligent visual measurement system adopted in the present invention is used to collect video images of coal material carried by the belt conveyor in real time by installing a binocular camera at the position directly above the belt conveyor perpendicular to the belt conveyor, and installing a speed sensor for real-time belt conveyor. Rotational speed measurement, and the video image of the coal material and the rotational speed of the belt are transmitted to the server for image analysis to obtain the carrying coal flow rate. The specific measurement steps are:

[0102] Step 1: Use the binocular camera to collect the left and right video images of the coal carried by the belt conveyor, and perform image preprocessing on the image of the coal carried. The specific process of the image preprocessing is:

[0103] Step 1-1: Use the Bouguet image correction algorit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com