Device for eccentric separation and residue-free cement removal of elbow cement nozzle

A residue-free, glue-nozzle technology, used in devices for coating liquids on surfaces, spraying devices, coatings, etc., can solve the problems of complete separation of glass glue and stainless steel glue nozzles, waste of resources, and very large use, etc. Conducive to recycling and improving the efficiency of manual work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

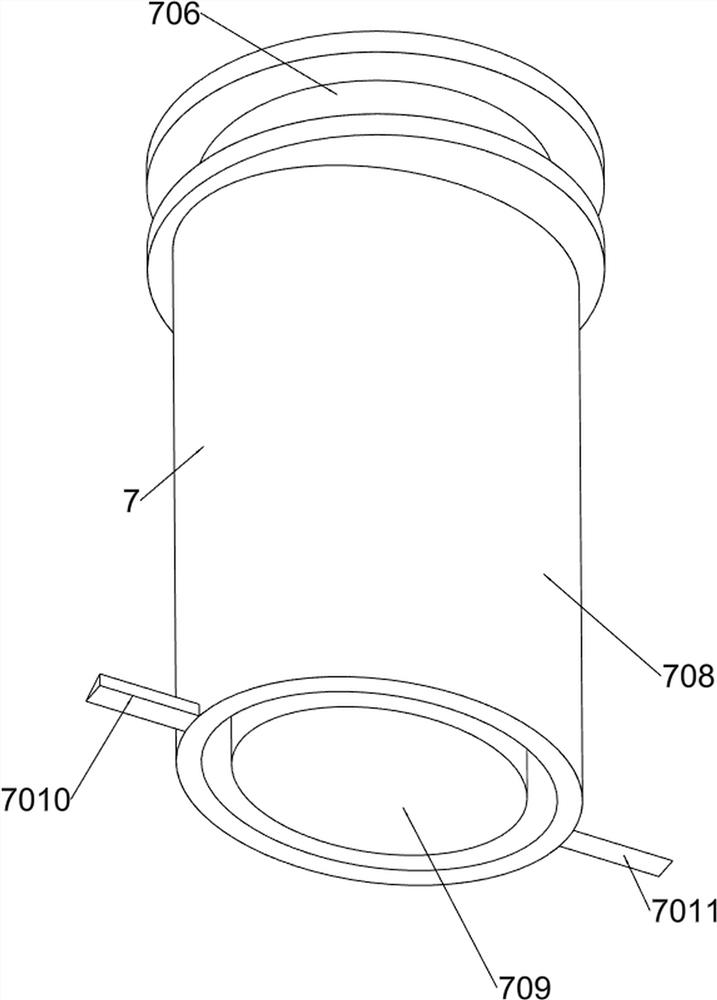

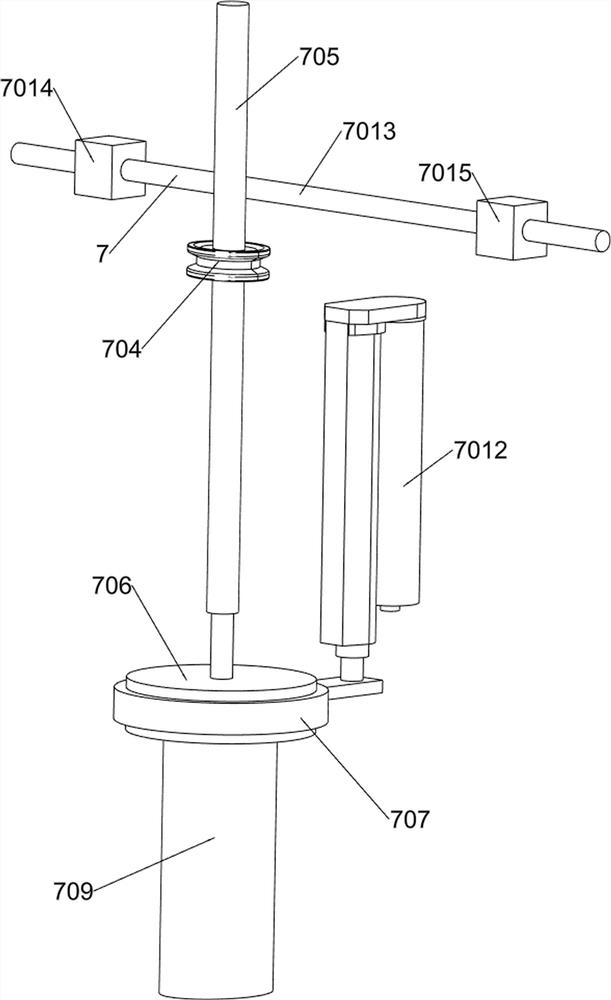

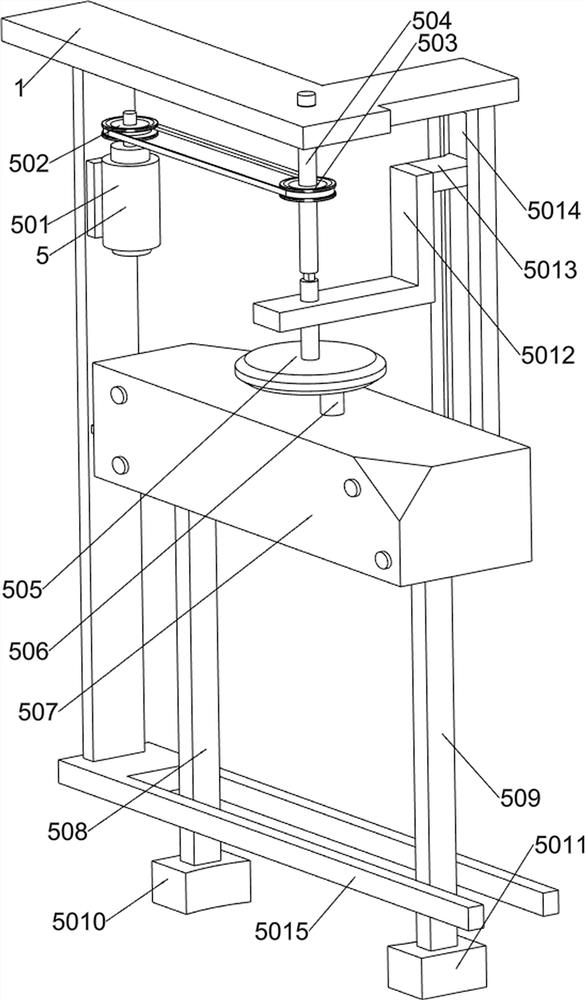

[0031] A device for eccentric separation of elbow glue nozzles and non-residual glue removal, such as Figure 1-10 As shown, it includes a main support frame 1, a control panel 2, a transmission mechanism 3, a limit separation seat 4, a nozzle head separation system 5, a transfer system 6 and a glue removal system 7; the main support frame 1 is used for supporting devices; the control panel 2 is fixedly connected with the main support frame 1; the transmission mechanism 3 is fixedly connected with the main support frame 1; the limit separation seat 4 is connected with the transmission mechanism 3; the nozzle head separation system 5 is connected with the main support frame 1; the transfer system 6 It is connected with the main support frame 1; the glue removal system 7 is connected with the main support frame 1.

[0032] Working principle: When you need to use this device, first place the device horizontally at the place to be used, turn on the power, then turn on the control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com