Meat can trademark printing device

A technology for printing devices and cans, which is applied in the directions of printing devices, printing, typewriters, etc., to achieve the effect of convenient collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

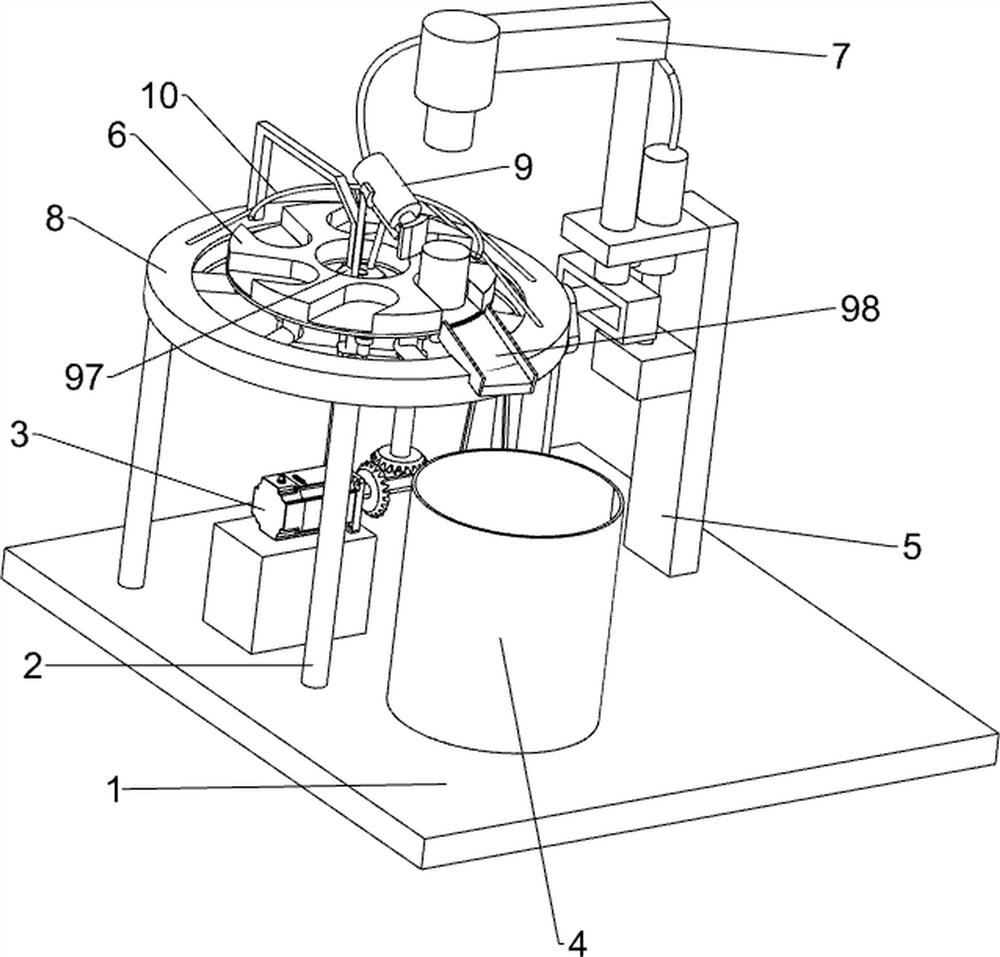

[0021] A kind of canned meat trademark printing device, such as figure 1 As shown, it includes a base 1, a first bracket 2, a servo motor 3, a finished product basket 4, a second bracket 5, a rotating mechanism 6, a lifting mechanism 7 and a circular slide rail 8, and the first bracket is uniformly arranged on the rear side of the top of the base 1 2. The number of the first support 2 is 4, the top of the first support 2 is connected with a ring slide rail 8, the servo motor 3 is provided on the left rear side of the top of the base 1, the finished product basket 4 is placed on the front side of the top of the base 1, and the base 1. A second bracket 5 is provided on the right rear side of the top, and a lifting mechanism 7 is connected to the second bracket 5. The parts of the lifting mechanism 7 are connected with the output shaft of the servo motor 3, and the rotating mechanism 6 is connected between the tops of the ring slide rails 8. The components of the swivel mechanism...

Embodiment 2

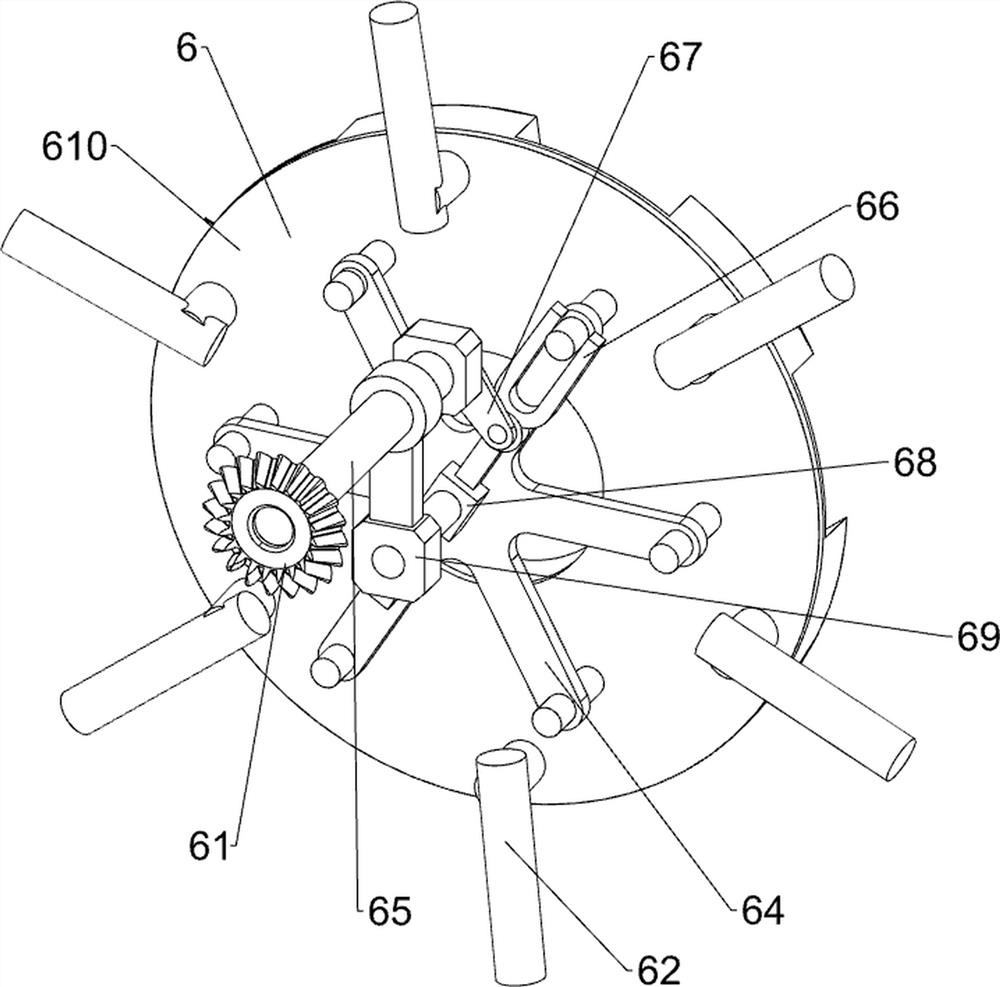

[0024] On the basis of Example 1, such as Figure 2-4 As shown, the rotating mechanism 6 includes a first bevel gear 61, a slide bar 62, a support frame 63, a turret 64, a first rotating shaft 65, a push rod 66, a rotating rod 67, a sliding sleeve 68, a fixed seat 69, and a rotating disk 610 , the bearing seat 611 and the fixed rod 612, the circular slide rail 8 is evenly connected with the slide bar 62 in the circumferential direction, the top of the slide bar 62 is connected with the rotating disk 610, and the middle side of the bottom of the rotating disk 610 is connected with the turret 64, wherein The tops of the three first brackets 2 are all provided with a support frame 63, and the support frame 63 is connected with a fixed seat 69, and the front part of the fixed seat 69 is connected with a bearing seat 611, and the bearing seat 611 is rotationally connected with the first rotating shaft 65. The bottom of a rotating shaft 65 is provided with a first bevel gear 61, the...

Embodiment 3

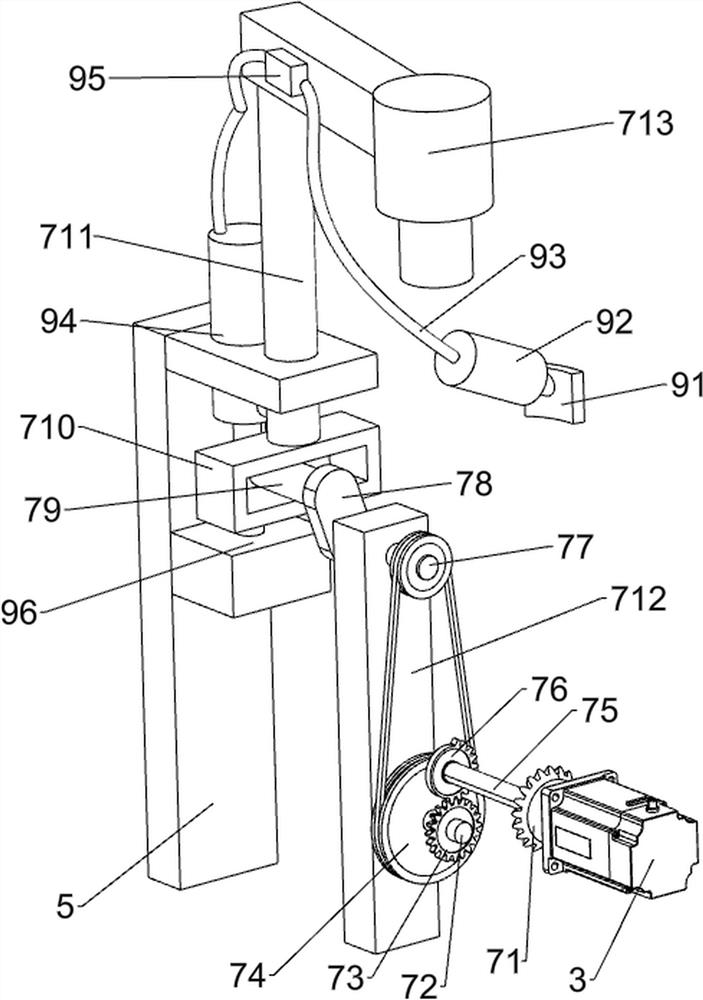

[0029] On the basis of Example 2, such as figure 1 and Figure 4 Shown, also include pusher mechanism 9, pusher mechanism 9 includes first piston 91, first cylinder body 92, connecting pipe 93, second cylinder body 94, fixed block 95, second piston 96, fixed mount 97 And the blanking plate 98, the bottom of the front side of the fixed rod 612 is connected with a fixed frame 97, the top of the fixed frame 97 is provided with a first cylinder 92, the right side of the first cylinder 92 is slidingly connected with a first piston 91, and the second support 5 A second cylinder 94 is provided on the rear side of the top, and a second piston 96 is provided at the bottom of the second cylinder 94. The second piston 96 is squeezed and fitted with the rectangular sliding sleeve 710, and a fixed block 95 is provided on the rear side of the left part of the stamp 713. A connecting pipe 93 is connected between the first cylinder body 92 and the second cylinder body 94, and the connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com