Self-rotating dustproof reversing camera

A camera and self-rotation technology, used in vehicle maintenance, image communication, vehicle components, etc., can solve the problems of seeing the rear of the vehicle, dust contamination, blurred camera acquisition, etc., to ensure clarity and maintain cleanliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

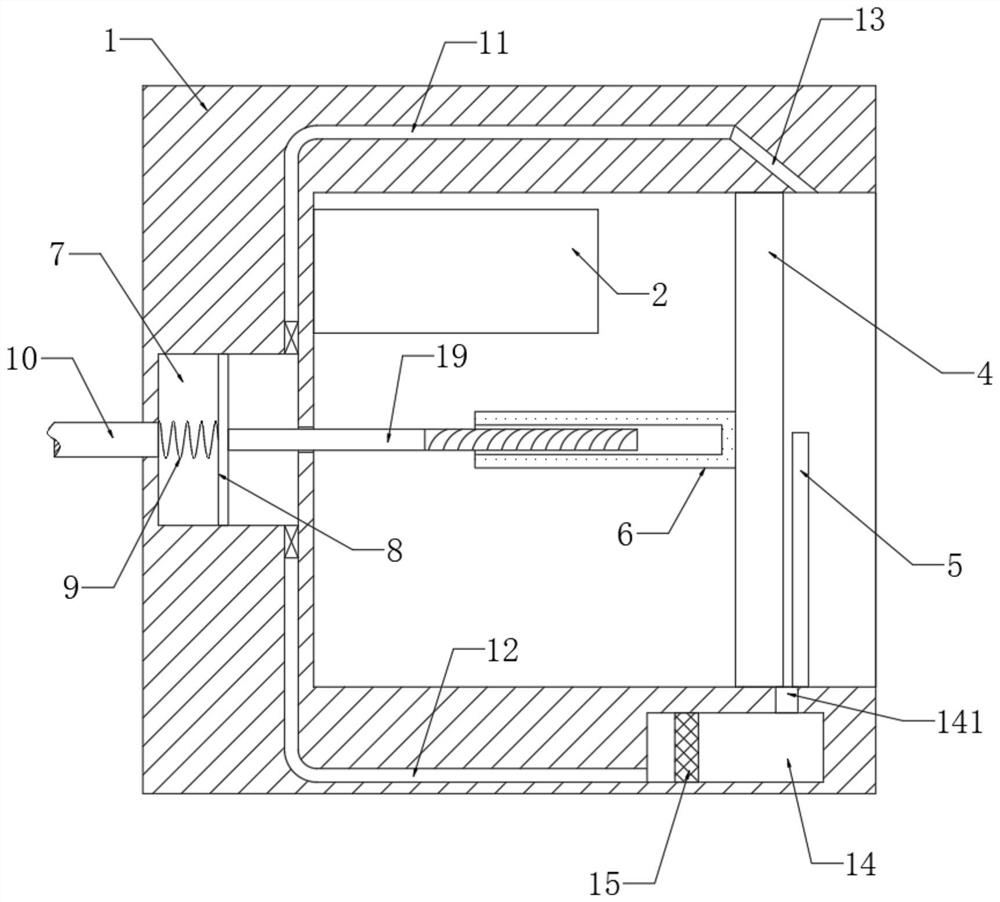

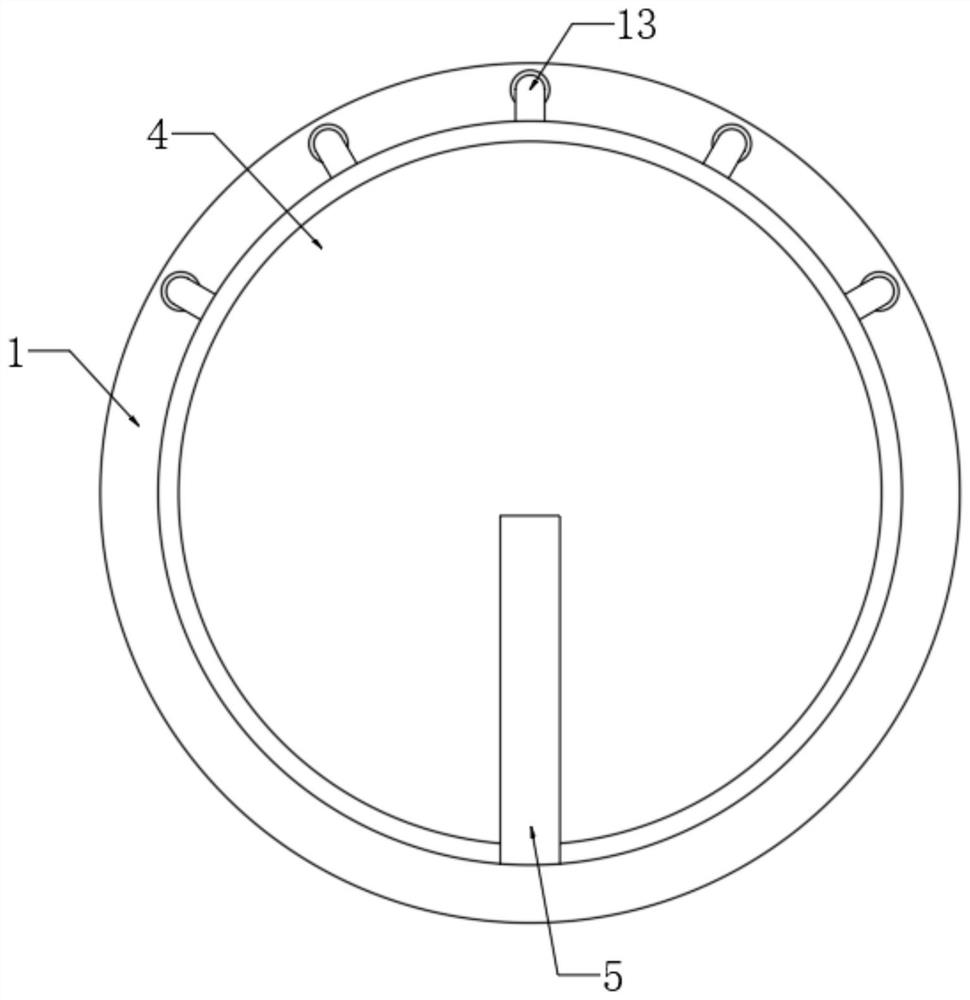

[0022] refer to Figure 1-2 , a self-rotating dust-proof reversing camera, including a lens barrel 1, a camera body 2 is installed in the lens barrel 1, a circular lens 4 is connected to the lens barrel 1 for rotation, and a brush plate is fixedly connected to the inner bottom of the lens barrel 1 5. The side wall of the lens 4 is fixedly connected with a threaded sleeve 6, and the internal thread of the threaded sleeve 6 is connected with a screw 19. The side wall of the lens barrel 1 is provided with an air intake slot 7, and a driving screw 19 is installed in the air intake slot 7 to reciprocate Mobile drives.

[0023] The driving device includes a piston 8 that is sealed and slidably connected in the air inlet groove 7, and the end of the screw rod 19 away from the threaded sleeve 6 is fixedly connected to the side wall of the piston 8. It should be noted that, as figure 1 As shown, the threaded part of the screw rod 19 is only distributed on a part of the screw rod 19 cl...

Embodiment 2

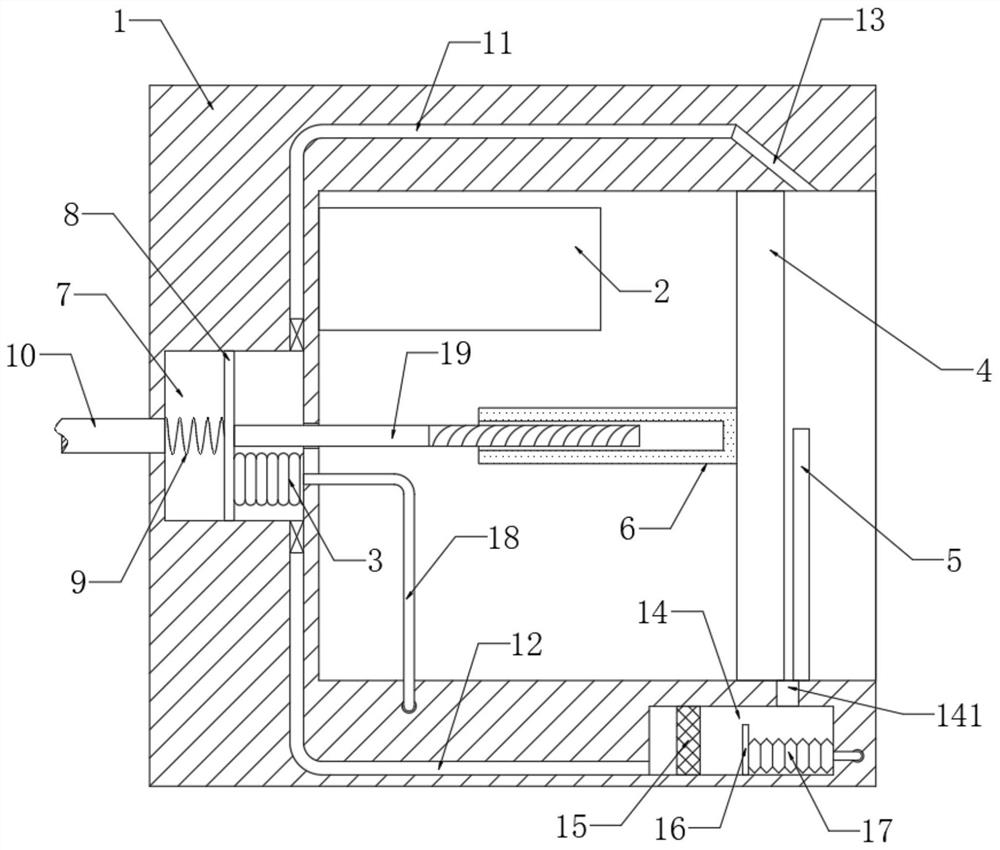

[0028] refer to image 3 , different from Embodiment 1, the clapper 16 is slidably connected in the dust storage tank 14, the side wall of the clapper 16 is fixedly connected with a telescopic air bag 17, and the end of the telescopic air bag 17 away from the clapper 16 is fixedly connected to the side wall of the dust storage tank 14 Above, the bellows 3 is fixedly connected between the piston 8 and the inner wall of the air intake groove 7 , and the bellows 3 communicates with the telescoping airbag 17 through the conduit 18 . It should be noted that both ends of the bellows 3 are blocked by the piston 8 and the inner wall of the air intake groove 7, which can ensure that the air can flow back and forth from the bellows 3 and the telescopic air bag 17 when the piston 8 moves back and forth.

[0029] In this embodiment, when the piston 8 moves back and forth in the air intake groove 7, it will continuously squeeze the bellows 3, blow the air in the bellows 3 into the telescop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com