Intelligent workpiece storage transfer trolley

A technology for transferring vehicles and workpieces, which is applied in trolleys, motor vehicles, multi-axis trolleys, etc., can solve the problems of difficult appearance protection, low workpiece transfer efficiency, and easy confusion of similar workpieces, and achieves reduction of bump damage, small footprint, Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing, the present invention will be further described:

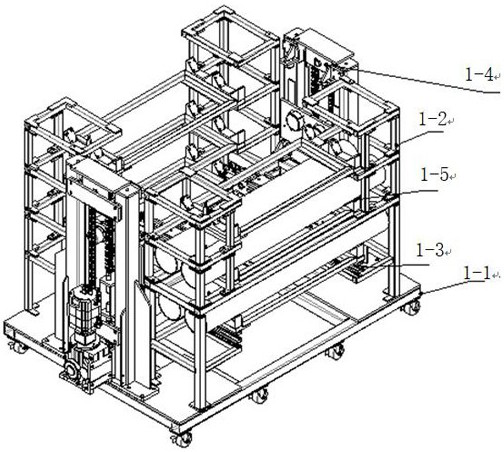

[0035] like figure 1 , an intelligent workpiece storage transfer vehicle, comprising a transfer vehicle main body 1, a protective cover 2, a control unit, a battery, a touch screen 5, an automatic door 4, an observation window 3, casters 6, a handle 7, a protective cover covering 2 and a transfer vehicle main body 1, The automatic door 4, the touch screen 5, and the observation window 3 are arranged on the side wall of the protective cover 2, and the two handles 7 are arranged on the front and rear walls of the protective cover 2. Several casters 6 are arranged at the bottom of the main body 1 of the transfer vehicle. The casters 6 have The braking function can make the transfer vehicle reliably stop at a certain position; the storage battery and the control unit are arranged on the main body 1 of the transfer vehicle.

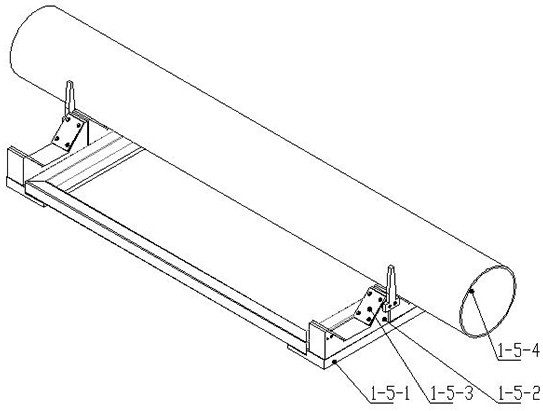

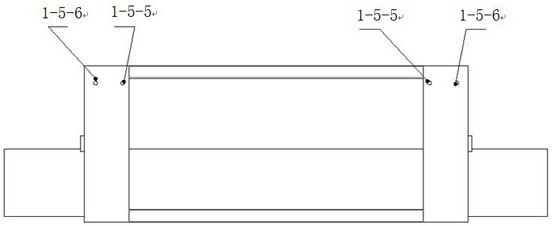

[0036] like figure 2 , the main body 1 of the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com