Container anti-overflow method and anti-overflow container

An anti-overflow, container technology, applied in the direction of containers, rigid containers, packaging, etc., can solve the problems of inconvenient operation, improper dosage, easy overturning or dumping, etc., to improve the utilization rate and avoid waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

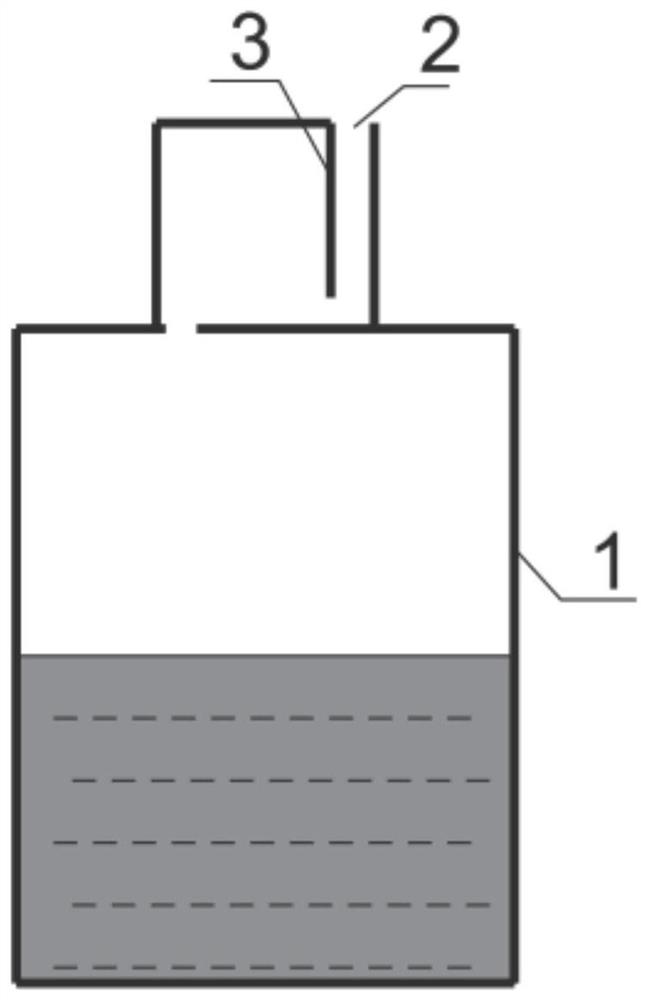

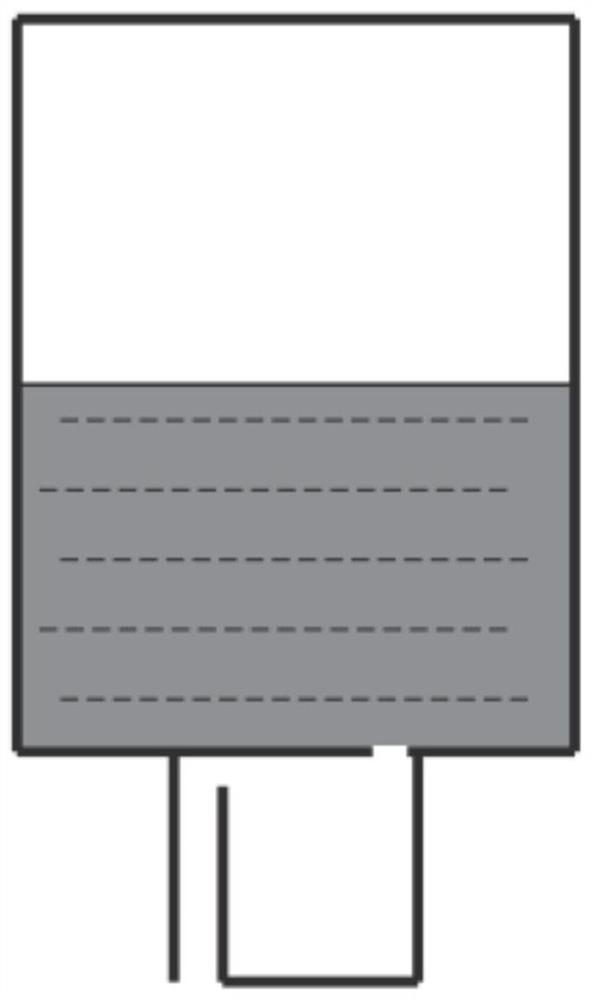

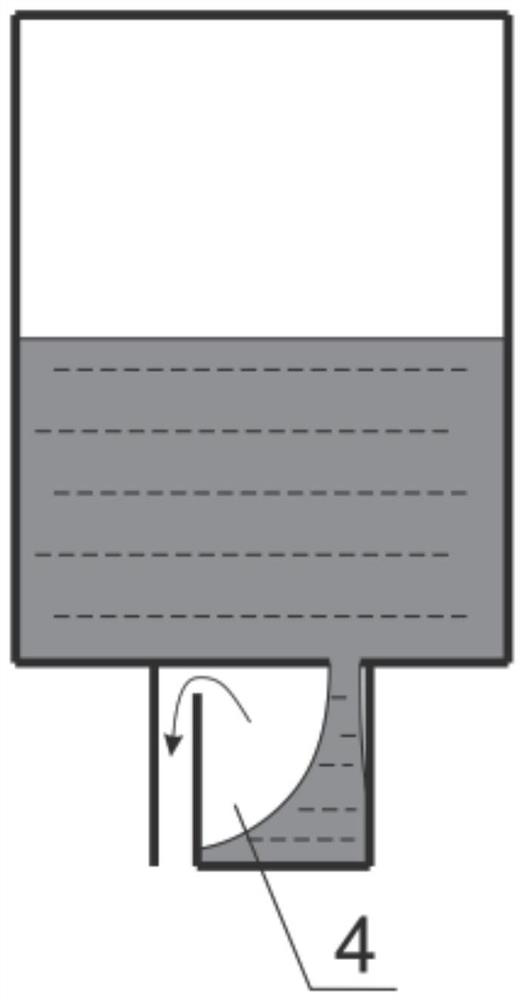

[0046] This embodiment discloses a method for container overflow prevention, such as figure 1 As shown, the container 1 includes a liquid outlet 2 arranged at the upper end. When the container is placed upright, the liquid is at the bottom of the container 1. When the container is turned upside down, as figure 2 As shown, the liquid converges to the side of the liquid outlet 2 in the container 1 and starts to flow toward the liquid outlet; generally, in order to maintain the balance of internal and external pressure, when the liquid flows out of the liquid outlet, there will be gas rushing into the container. When the anti-overflow cannot be achieved. Therefore, in order to prevent the liquid from directly flowing out of the liquid outlet 2 when the container 1 is inverted, as image 3 As shown, before the liquid flows to the liquid outlet, the intercepting structure 3 first intercepts the liquid flowing to the liquid outlet, and in the process of making the liquid flow to t...

Embodiment 2

[0048] This embodiment discloses a container with a labyrinth channel-shaped slow flow chamber and an overflow prevention method based on the container, such as Figure 5 As shown, the container of the labyrinth channel-shaped slow flow chamber includes a bottle cap 5 and a bottle body 6, and the bottle cap 5 matches the bottle mouth of the bottle body 6, as Figure 6 , 7 As shown, the bottle cap 5 is provided with a liquid outlet 51, and the bottle cap 5 is provided with a slow flow chamber 52, and the slow flow chamber 52 is provided with a labyrinth flow channel 53.

[0049] Such as Figure 7 , 8 as shown, Figure 7 , 8 It is a structural diagram of a bottle cap with or without a bottom cap at the same position and at the same angle. The bottom of the slow flow chamber 52 is provided with a bottom cap 54, and the bottom cap 54 is provided with a liquid inlet 541; 541 into the labyrinth channel 53 in the slow flow chamber 52; the labyrinth channel 53 includes a plurali...

Embodiment 3

[0055] This embodiment discloses a container with a liquid outlet column-liquid storage chamber type slow flow chamber and an overflow prevention method based on the container. The liquid outlet column is arranged at a central position, such as Figure 11 As shown, the container containing the liquid outlet-liquid storage type slow flow chamber includes a bottle cap 7 and a bottle body 8, the bottle cap 7 coincides with the bottle mouth of the bottle body 8, and the bottle cap 7 is provided with a liquid outlet 71, The liquid outlet 71 is set at the center of the bottle cap 7, and the bottle cap 7 is provided with a slow flow chamber 72, and the slow flow chamber 72 is provided with a liquid outlet column-liquid storage chamber 73.

[0056] Such as Figure 12 As shown, the slow flow chamber 72 is provided with a partition 721, the partition 721 separates the slow flow chamber into a liquid outlet column-liquid storage chamber structure 73, and the flow channel connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com