Tungsten hexafluoride preparation device and method for improving utilization rate of raw materials

A technology of tungsten hexafluoride and preparation device, applied in tungsten halide and other directions, can solve the problems of affecting the preparation effect, easy deposition of metal tungsten powder, reducing preparation quality, etc., and achieve the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments, but it is not intended to limit the patent of the present invention.

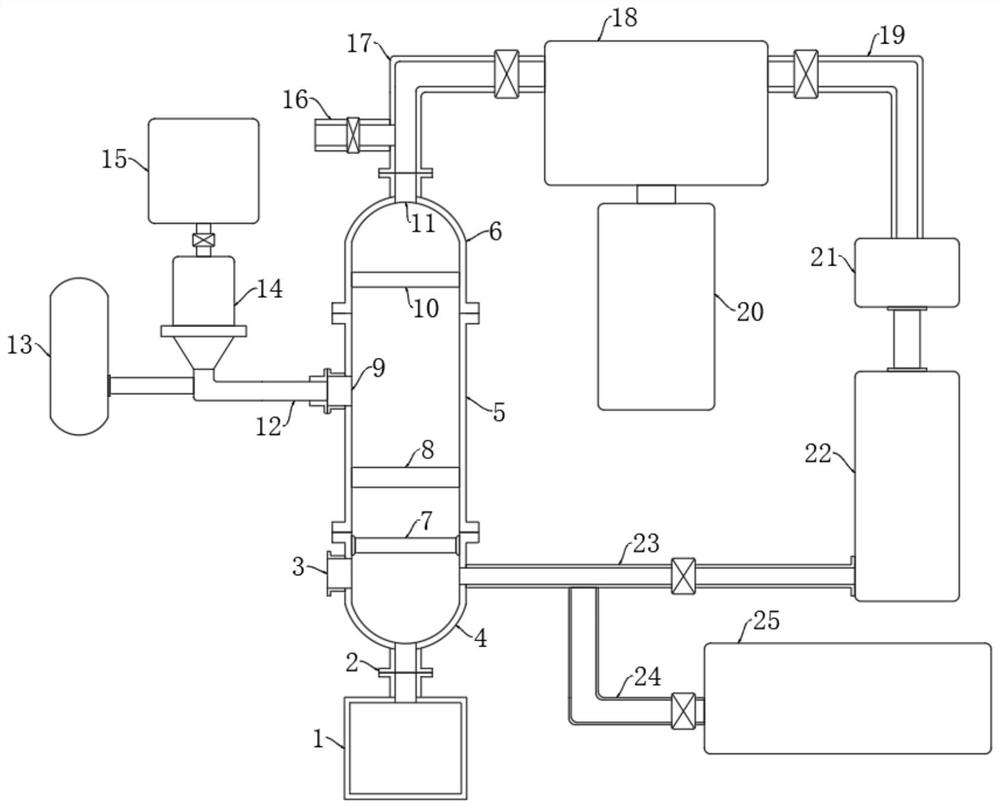

[0027] A tungsten hexafluoride preparation device for improving the utilization rate of raw materials, such as figure 1 As shown, the device includes a recovery tank 1, a fluidized bed reactor, a purge gas pipe 16, a condenser 18, a collection tank 20, a compressor 21, a buffer tank 22, a fluorine-containing mixed gas tank 25 and a feeding mechanism.

[0028] The recovery tank 1 is communicated with the fluidized bed reactor through the connecting pipeline 2, and the top of the fluidized bed reactor is provided with an air outlet 11, which is communicated with the condenser 18 through the first pipeline 17, and between the condenser 18 and the collection tank 20 The condenser 18 is communicated with the compressor 21 through the second pipeline 19, the compressor 21 is communi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com