Cable shearing mechanism with adjustable shearing length

A cutting mechanism and cable technology, which is applied in the field of cable cutting devices, can solve problems such as the inability to meet the cutting needs of cables of different lengths, and achieve the effects of preventing deviation, increasing cutting speed, and controlling precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0052]Example 1

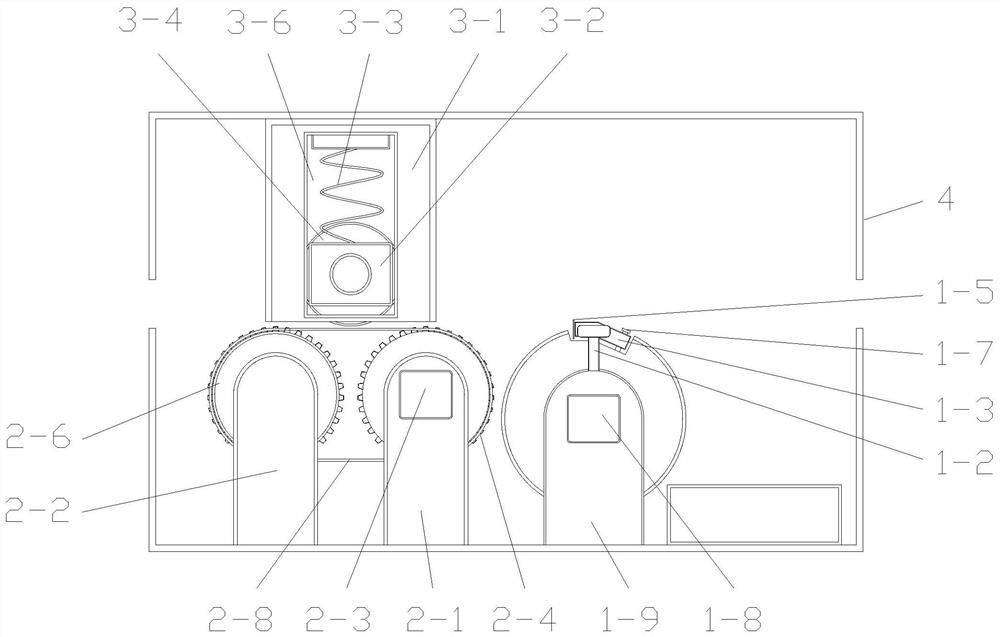

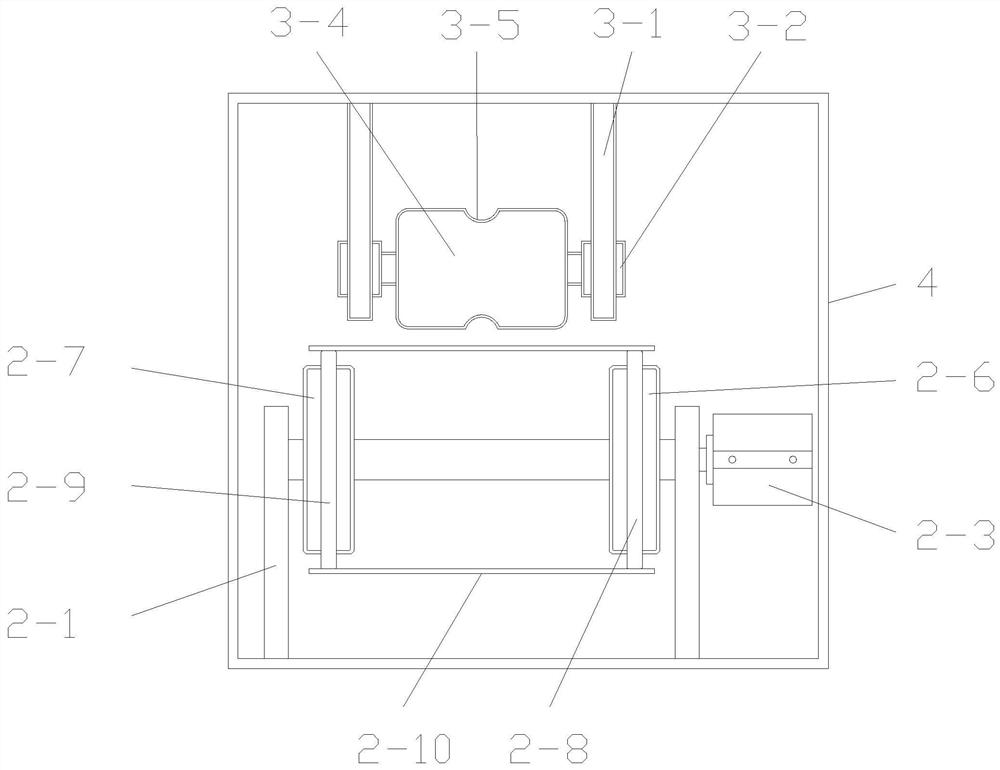

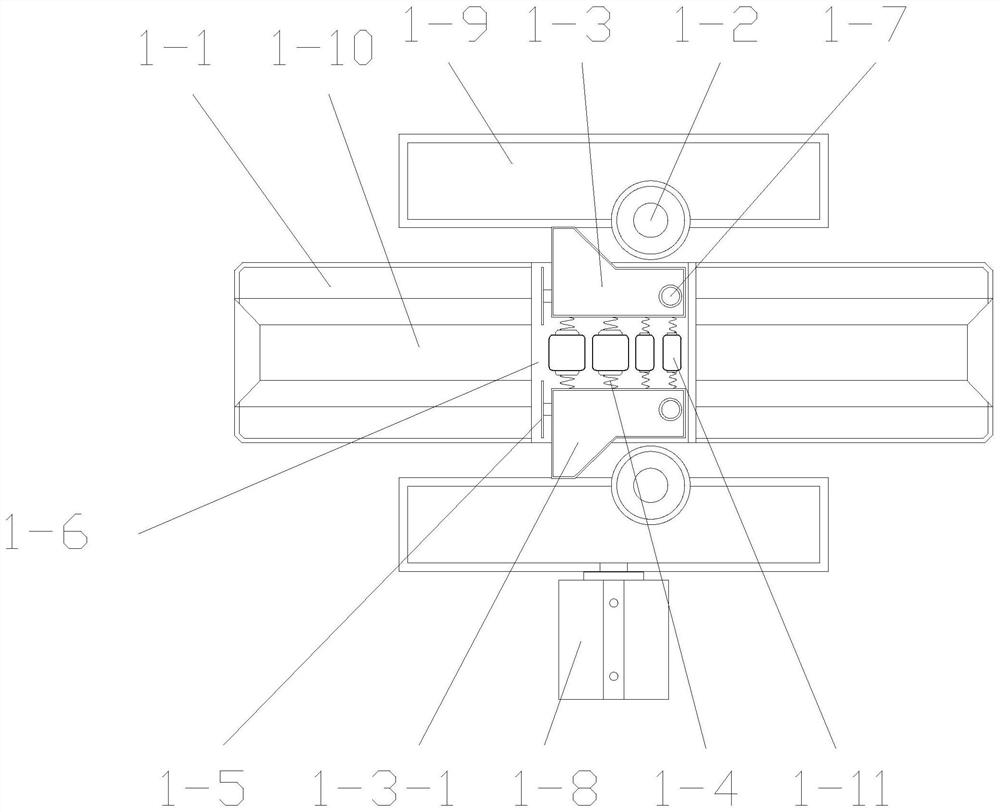

[0053]Cable shear mechanism adjustable with shear length, such asfigure 1 withFigure 3 ~ 5As shown, two first support columns 1-9, first rotating electric machine 1-8, shear wheel 1-1, two limit cylinders 1-2, clamping assembly, two blades 1-5, two Second Rotary Motor 1-13, four roller rollers 1-11; the clamping assembly includes two fixed cylinders 1-7, two connecting blocks 1-3, and the first retractable member 1-4. Two first support columns 1-9 are set inside and outside (pressfigure 1 The orientation shown), and the lower end is fixed to the bottom of the inner wall of the outer frame 4. The first rotating electric machine 1-8 is provided on one of the first support columns 1-9; the shear wheel 1-1 is axially connected to the rotation shaft of the first rotating electric machine 1-8, and is located in two first support columns 1 -9 between. There is a gap 1-6 on the circumferential surface of the shear wheel 1-1; the circumference of the shear wheel 1-1 is provide...

Example Embodiment

[0058]Example 2

[0059]The difference from the first embodiment is that the limit cylindrical 1-2 is rotated by rotating the connection to the first support column 1-9 to achieve the rotation of the limit cylinder 1-2.

[0060]During the limit cylinder 1-2 clamps the opposing two connection blocks 1-3 by extrusion, the rotation of the limit cylinder 1-2 can reduce the friction between the connecting blocks 1-3, so It can reduce the wear of both, while also preventing the rotation of the shear wheel 1-1 causes hindrance.

Example Embodiment

[0061]Example 3

[0062]The difference from the first embodiment is that the equal spacing at the circumferential surface of the shear wheel 1-1 is provided with two gaps 1-6, and a set of clamp assemblies are provided in each of the notches 1-6. The total number of blades 1-5 and the second rotating electric machine 1-13 is four, and the total number of the roller 1-11 is eight.

[0063]Two gaps 1-6 are provided by equal spacing, and the shear wheel 1-1 rotates two shears, and the speed of the shear wheel 1-1 can be reduced in the case of the desired cable shear length. Thereby, thereby reducing the energy consumption during the running of the first rotating motor 1-8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com