A quick mold changing device for forming metal handicrafts

A kind of handicraft and fast technology, applied in metal processing equipment, manufacturing tools, equipment for handling casting molds, etc., can solve the problems of long installation time, slow mold changing speed, hidden safety hazards, etc., and achieve the efficiency of installation and disassembly, and the installation speed. Fast and stable installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

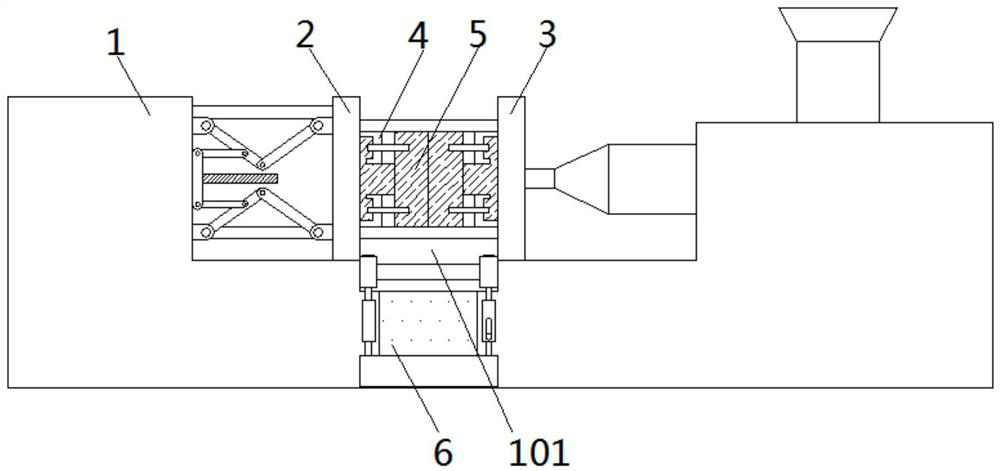

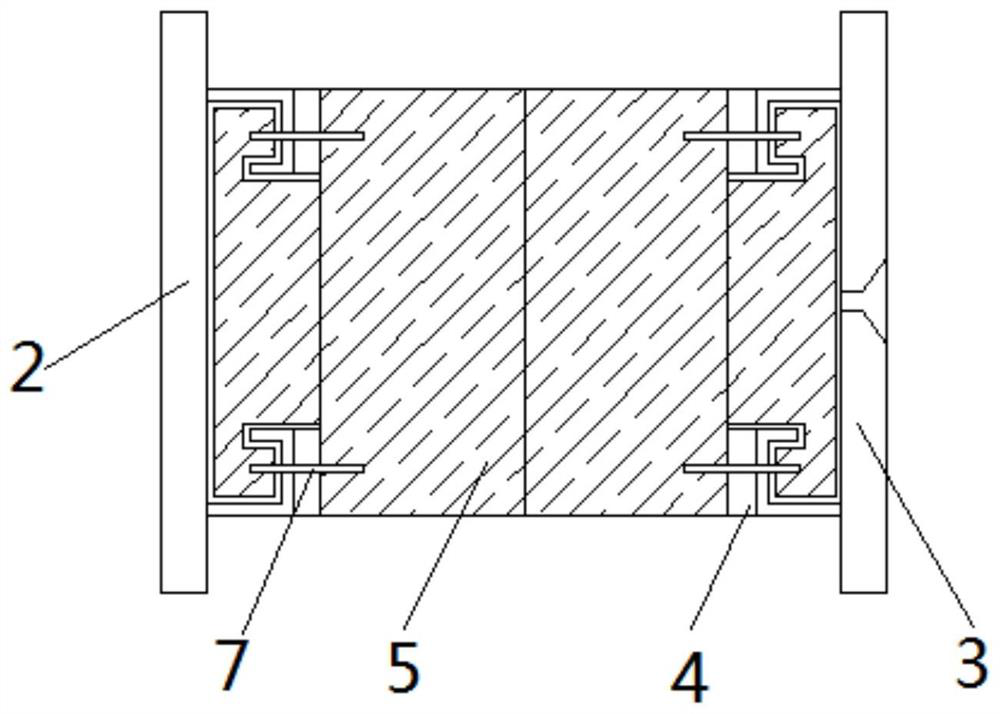

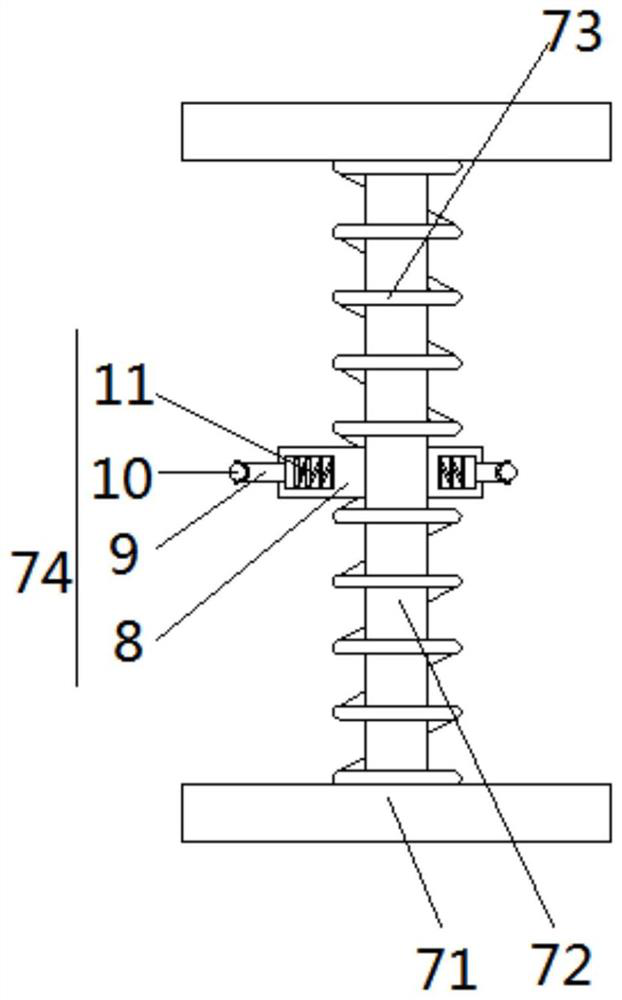

[0029] as attached figure 1 to attach Figure 8 Shown: a quick mold changing device for forming metal handicrafts, including an injection molding machine body 1, a blanking gap 101, a movable template 2, a fixed template 3, a mold 5, and a mold changing device 6, characterized in that: an injection molding machine body 1 The movable template 2 and the fixed template 3 are respectively installed on the left and right sides of the upper end. The upper end of the injection molding machine body 1 is located between the movable template 2 and the fixed template 3. There is a blanking gap 101, and an inclined plate is fixedly connected in the blanking gap 101. The upper and lower ends of the adjacent side of the movable template 2 and the fixed template 3 are fixedly connected with a receiving plate 4. The receiving plate 4 is hook-shaped, and the receiving plate 4 between the upper and lower ends of the movable template 2 and the fixed template 3 is arranged oppositely. The receiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com