Door and window structure

A technology for doors and windows and window frames, applied in the field of doors and windows, can solve the problems of easy accumulation of dust and inconvenient cleaning of dust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

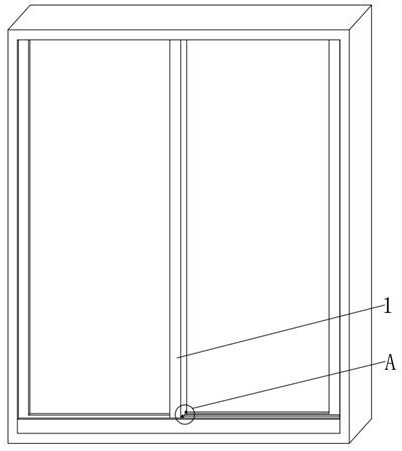

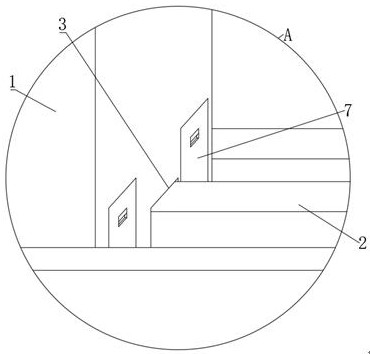

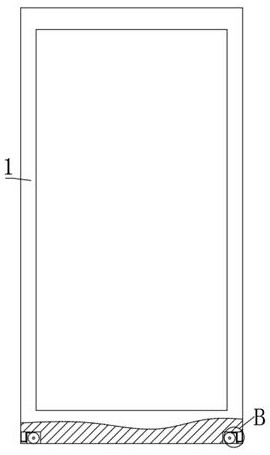

[0036] refer to Figure 1-8, a door and window structure, including two window frames 1 installed in the window frame, a tempered glass plate is bonded inside the window frame 1, a coaming plate and two guide plates 2 are fixed on the top and bottom of the inner wall of the window frame by bolts, The hoarding is arranged at the front end of the window frame 1, and the top and bottom of the window frame 1 are provided with guide grooves 3, the guide groove 3 is nested and connected with the corresponding guide plate 2, and two first grooves are provided on both sides of the bottom of the window frame 1 4 and the second groove 6, the inner wall of the first groove 4 is connected with the pulley 5 through bearing rotation, and the outer wall of the pulley 5 is provided with a plurality of ring grooves distributed evenly in the longitudinal direction, and a rubber ring is set in the ring groove, and the second groove 6. There is an ash collection box 7 built in. A dust guide plate...

Embodiment 2

[0047] refer to Figure 1-9 , a door and window structure, the dust guide plate 8 is arranged to be connected to the inner wall of the first groove 4 through bearing rotation, and the same third spring is fixed between the bottom of the dust guide plate 8 and the side wall of the first groove 4 by bolts 29.

[0048] During use, when the pulley 5 rotates, the force between the pulley 5 and the ash pushing plate 8 is transmitted to the ash guiding plate 8, and under the action of the third spring 29, the ash guiding plate 8 rotates back and forth at a certain angle, Thereby, the dust on the ash guide plate 8 is turned to the side close to the ash collection box 7, so that more dust is completely entered into the ash collection box 7 for collection, thereby further improving the dust cleaning effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com