Monitoring method for position of exhaust valve of marine low-speed machine

A technology for exhaust valves and low-speed machines, applied in mechanical equipment, engine components, machines/engines, etc., can solve problems such as easy failure of lubrication, stuck exhaust valve stem, excessive wear of exhaust valve stem, etc., to achieve satisfactory performance Effect of Exhaust Requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further elaborated and described below in conjunction with the accompanying drawings and specific implementation examples, but the protection scope of the present invention cannot be limited by this.

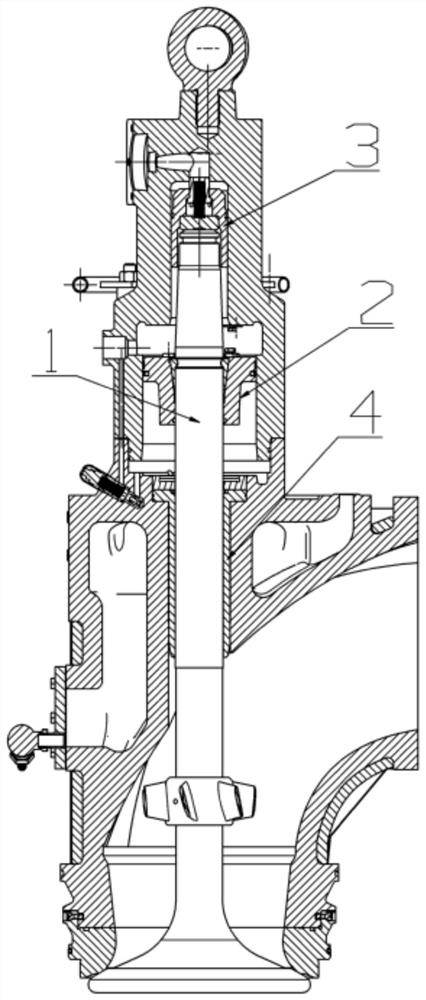

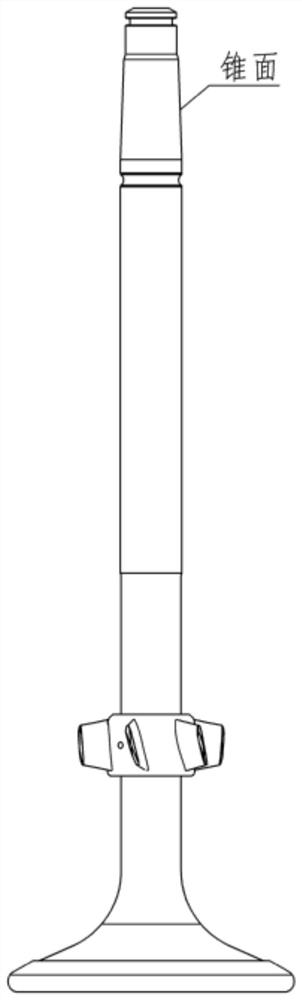

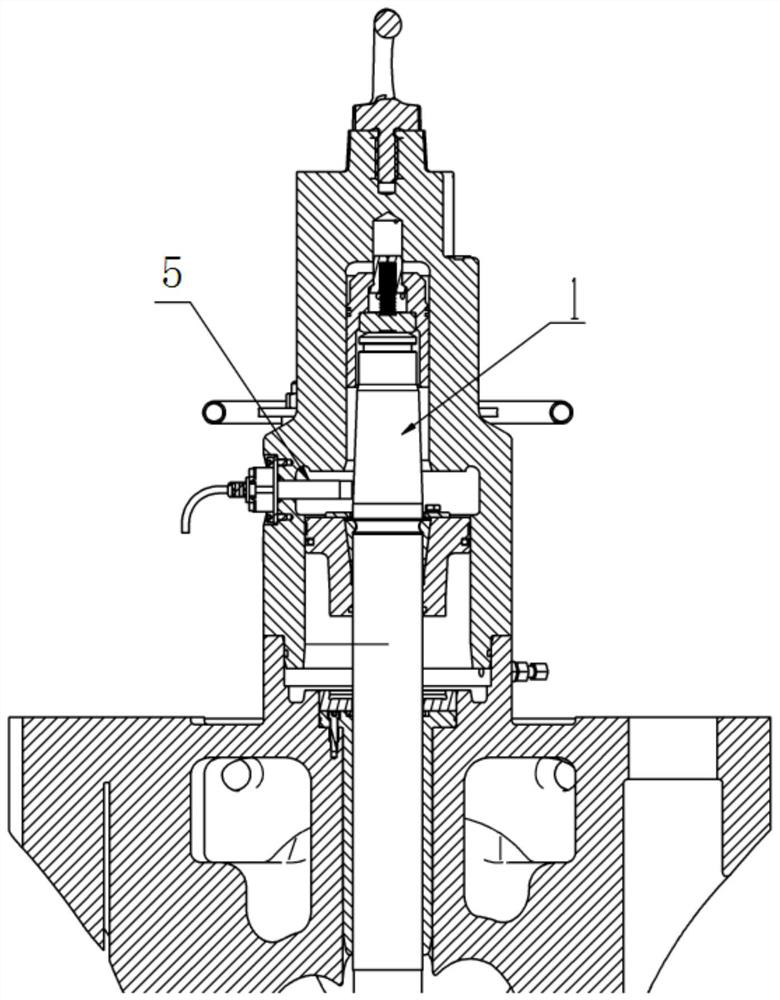

[0021] During the operation of marine low-speed engines, whether the timing of the exhaust valve switch is accurate is one of the factors that affect the performance and emissions of the main engine. During the operation of the main engine, the exhaust valve is subjected to high temperature and high pressure, and the entire exhaust valve stem is in a reciprocating state. In order to ensure the normal switching timing of the exhaust valve under severe working conditions, it is necessary to monitor the position of the exhaust valve stem in real time. monitor. Such as figure 2 The upper part of the shown exhaust valve stem is designed with a tapered surface, such as image 3 It is the relative position arrangement of the position sensor 5 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com