Work monitoring system for machine tool

A monitoring system and work technology, applied in the direction of test/monitoring control system, general control system, control/regulation system, etc., can solve problems without specific explanation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

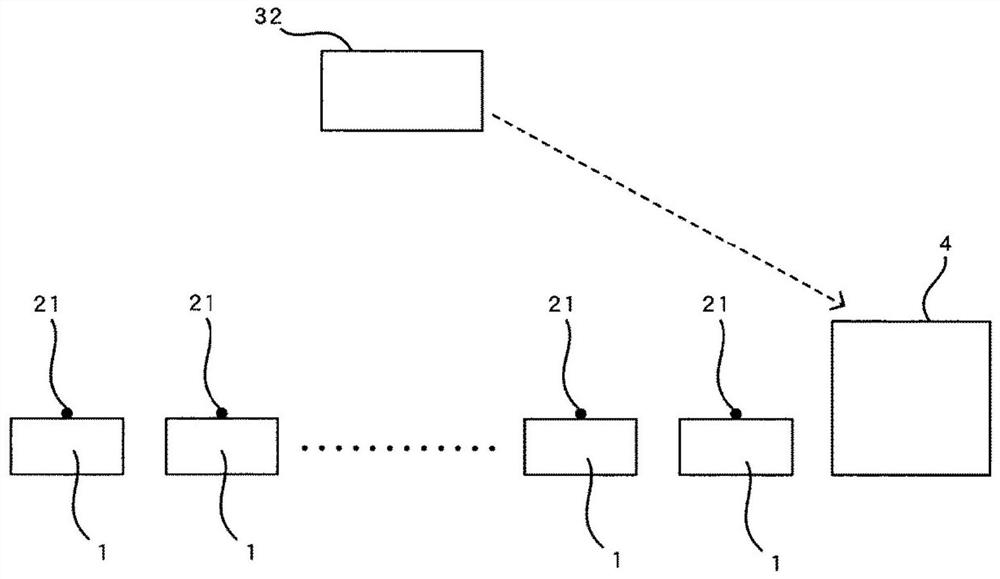

[0062] Embodiment 1 is based on the basic configuration (2), and is characterized in that, in each lamp 21, the color corresponding to the case within the normal operating range, the color corresponding to the case exceeding the normal operating range, and the color corresponding to the case of exceeding the normal operating range are respectively lit. And the color of the situation where the work is completed, at the place where the work monitoring of each machine tool 1 is carried out, specifically at the monitoring site 4, the change state of the color of each machine tool 1 is recorded, and the frequency of abnormal occurrence in each machine tool 1 is recorded. degree for statistics.

[0063] By counting the occurrence frequency of abnormalities in each machine tool 1 as described above, it is possible to statistically analyze problems and defects in the operation of each machine tool 1 .

Embodiment 2

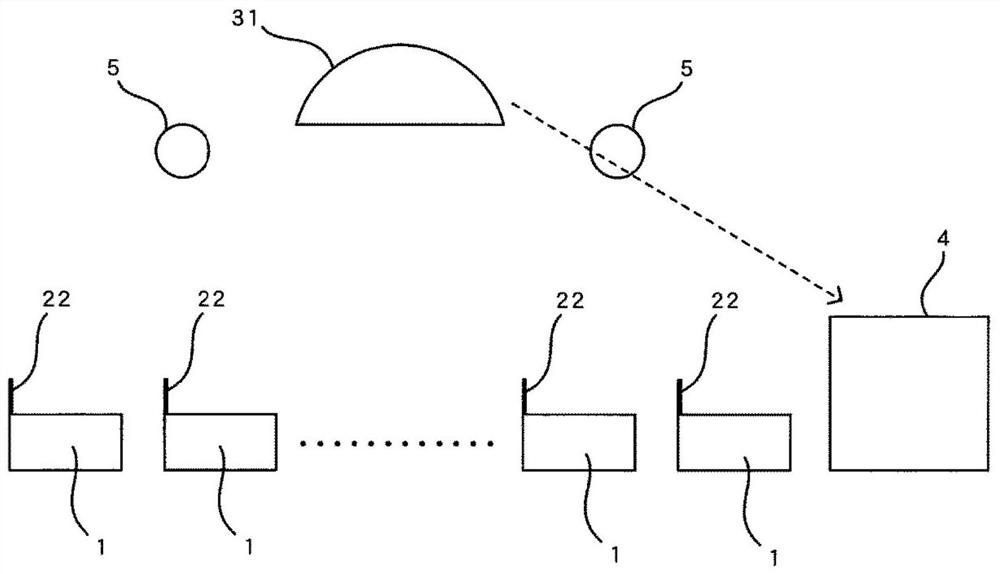

[0065] Embodiment 2 is based on the basic structure (1), and is characterized in that, in each reflective display panel 22, the position corresponding to the situation of normal operation and the position corresponding to the situation of exceeding the normal operation range are respectively set. position, and the position of the situation where the work is completed, and at the place where the work monitoring of each machine tool 1 is carried out, specifically at the monitoring site 4, the change state of the position of each reflector is recorded, and the abnormality in each machine tool 1 The frequency of occurrence is counted.

[0066] Also in the second embodiment, similarly to the first embodiment, problems and defects in the operation of each machine tool 1 can be statistically analyzed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com