Lubricating oil pump for engines or compressors

A lubricating oil pump and compressor technology, which is used in engine lubrication, engine lubrication with crankcase compressed fuel-air mixture, lubrication pump, etc., can solve long-term, troublesome pipeline system replacement, performance limitations, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

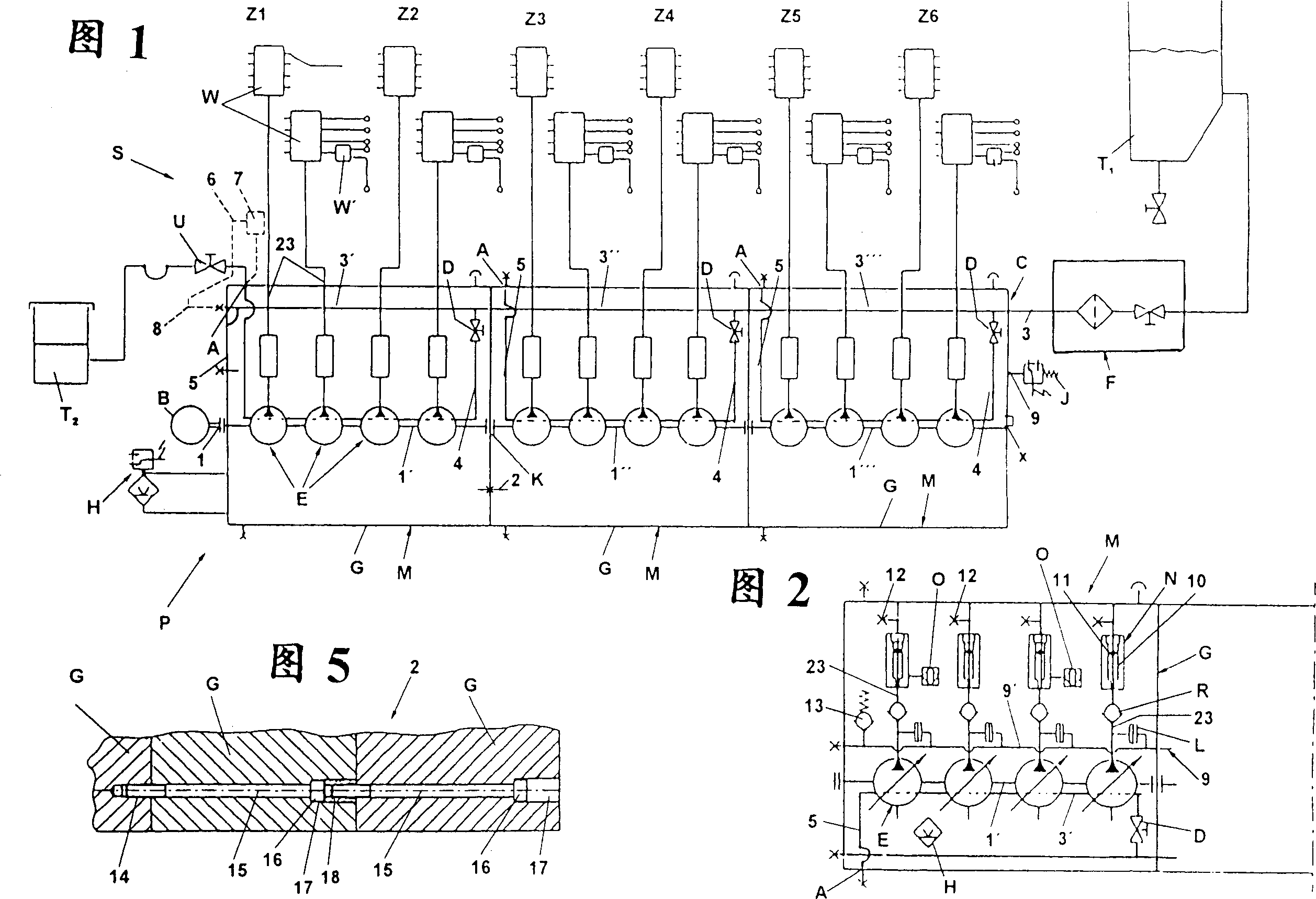

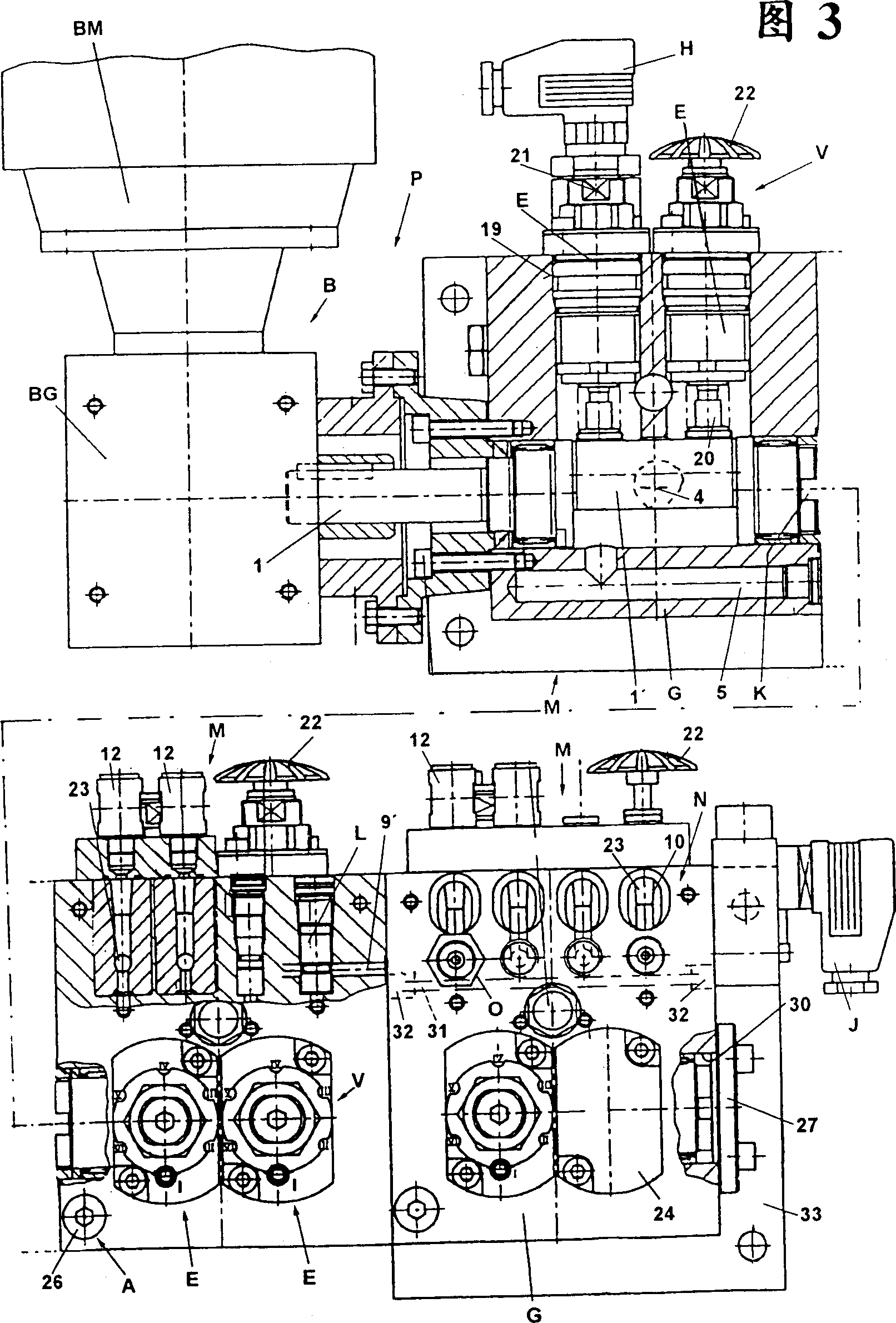

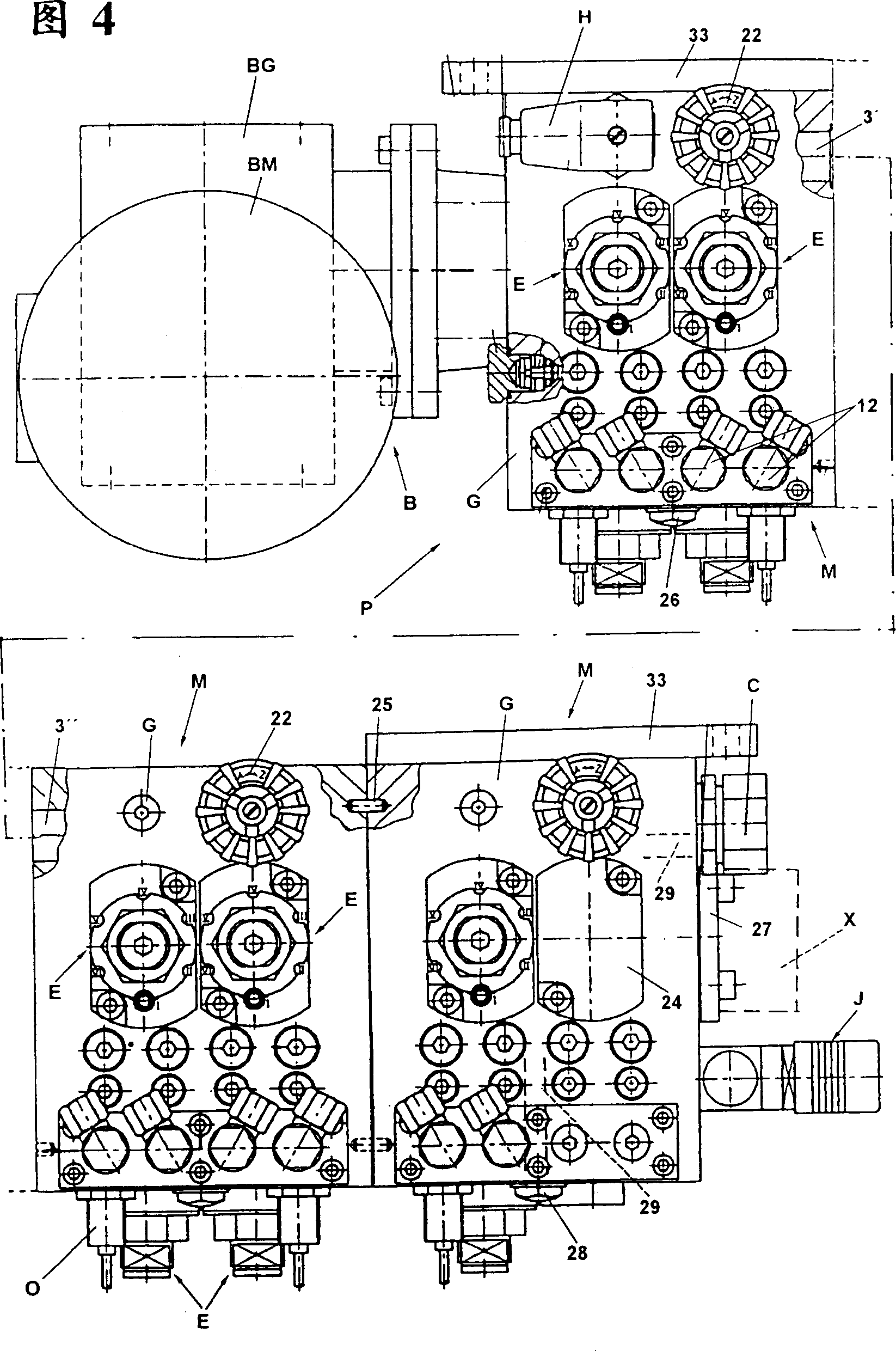

[0034] Cylinder lubricating system S for lubricating six cylinders Z1 to Z6 of medium or large diesel engines or compressors, such as two-stroke marine diesel engines, comprising as main components a cylinder lubricating oil pump P consisting of three pump building blocks M, many Sequential oil distributors W, W' and oil tanks T1, T2 (standard oil and running-in oil) corresponding to the number of cylinders. Each pump block M is housed in a box-shaped housing G in which four pump elements E are arranged via sequential oil distributors W for the upper and lower lubrication planes of cylinders Z1 to Z6, and via downstream The output valve of the sequential oil distributor W'.

[0035]The eccentric shaft sections 1', 1", 1'' belonging to the drive axis 1 leading to a combined drive B are supported in each housing. The eccentric shaft sections 1', 1", 1'' directly drive each pump element and pass through Couplings K are connected to each other. The housings G are interconnected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com