Irregular workpiece clamping device

A clamping device, irregular technology, applied in the direction of clamping device, positioning device, metal processing machinery parts, etc., can solve the problems of easy deviation in processing and difficult to achieve complete fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

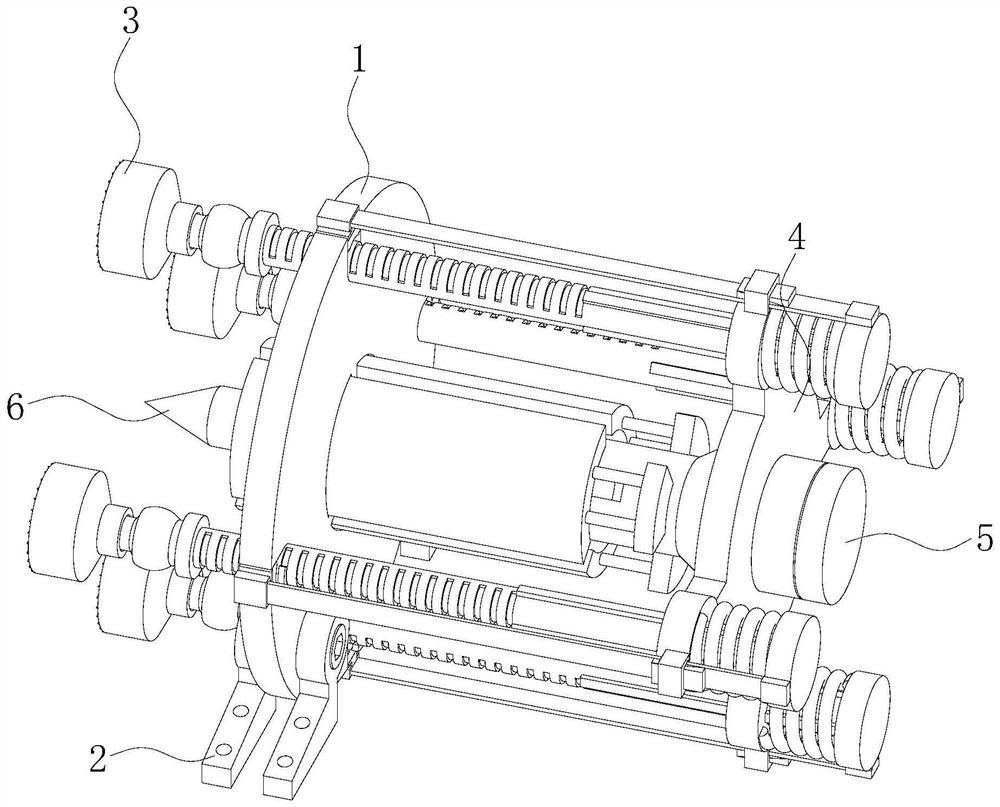

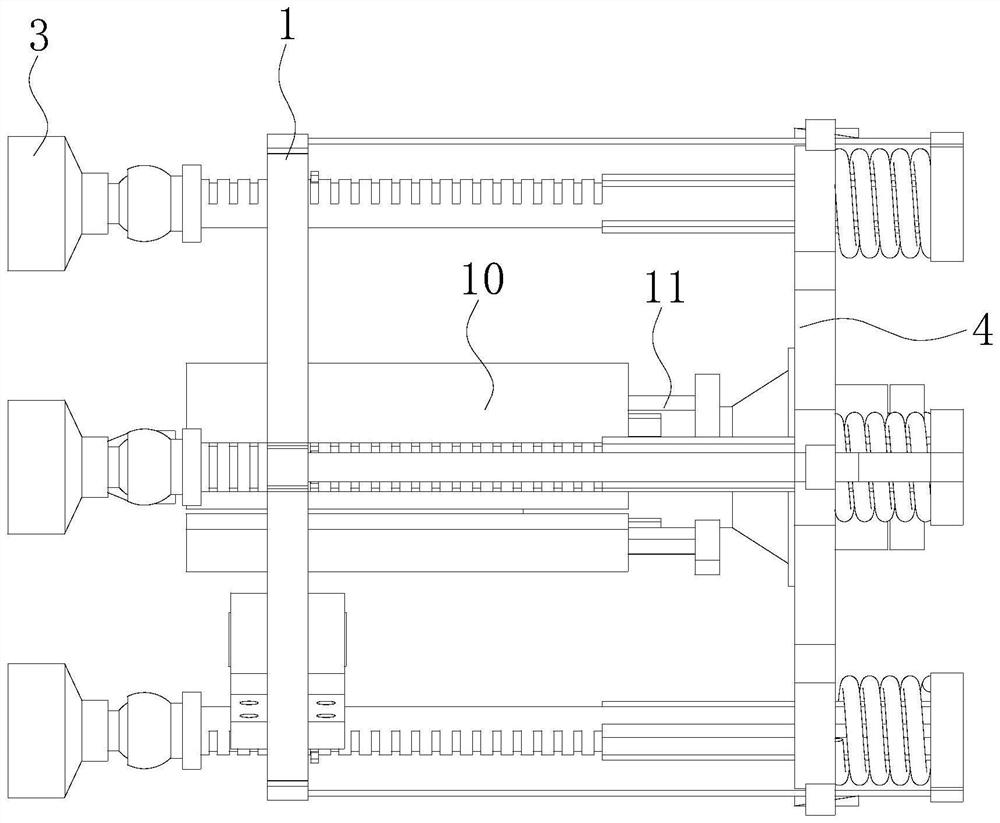

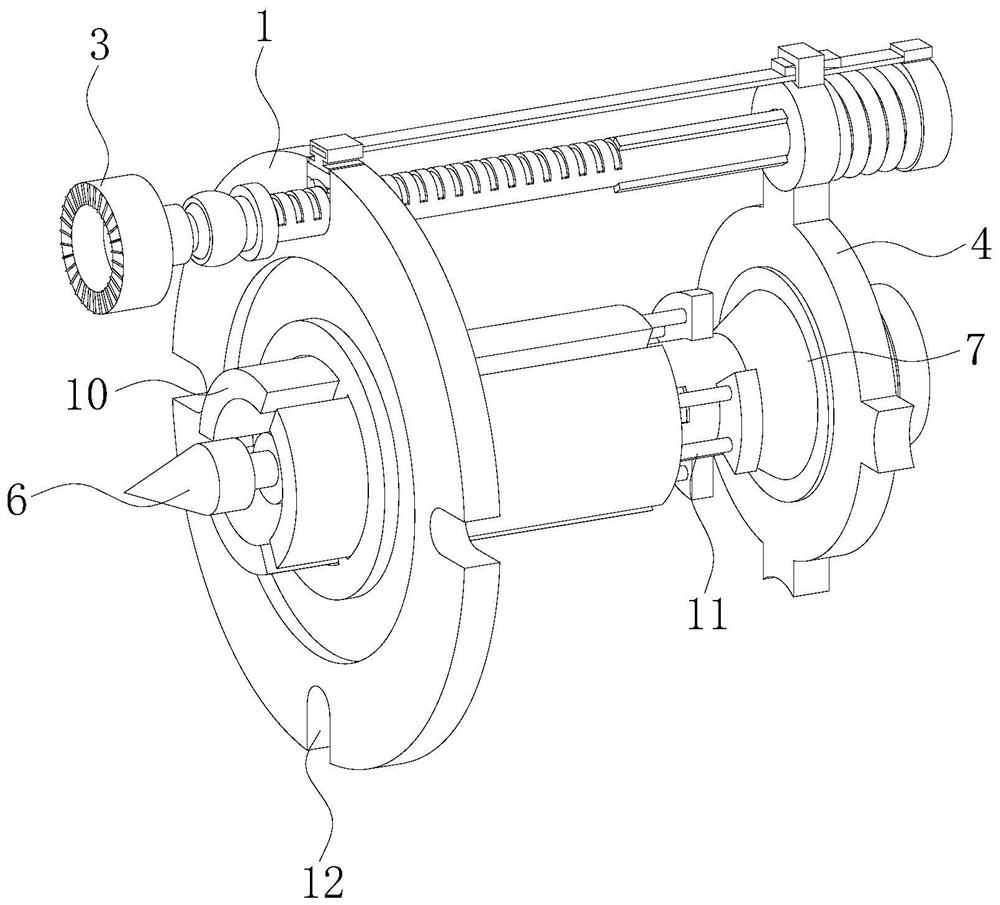

[0026] like Figure 1-7 As shown, an irregular workpiece clamping device includes a fixed plate 1 and two bases 2, the bases 2 are respectively located on the front and rear sides of the bottom surface of the fixed plate 1, the two bases 2 are fixedly connected with the fixed plate 1, and the fixed plate 1 Four limit mechanisms 3 are installed on the circumferential surface of the fixed plate 1, the fixed plate 1 is a circular structure, the limit mechanism 3 is vertically arranged with the fixed plate 1, and the four limit mechanisms 3 are distributed in a circular array equidistant from the axis line of the fixed plate 1 Setting, the right side of the fixed plate 1 is provided with a push plate 4, the right side of the push plate 4 is fixedly equipped with a force plate 5, the push plate 4 is a circular structure, the force plate 5 is concentrically arranged with the push plate 4, and the push plate 4 is set concentrically with the fixed plate 1, the force plate 5 cooperates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com