Online monitoring method for motor winding insulation

A winding insulation and insulation monitoring device technology, applied in the direction of motor generator testing, measuring electricity, measuring devices, etc., to achieve the effects of reducing economic losses, accurate detection, and reducing the risk of insulation failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

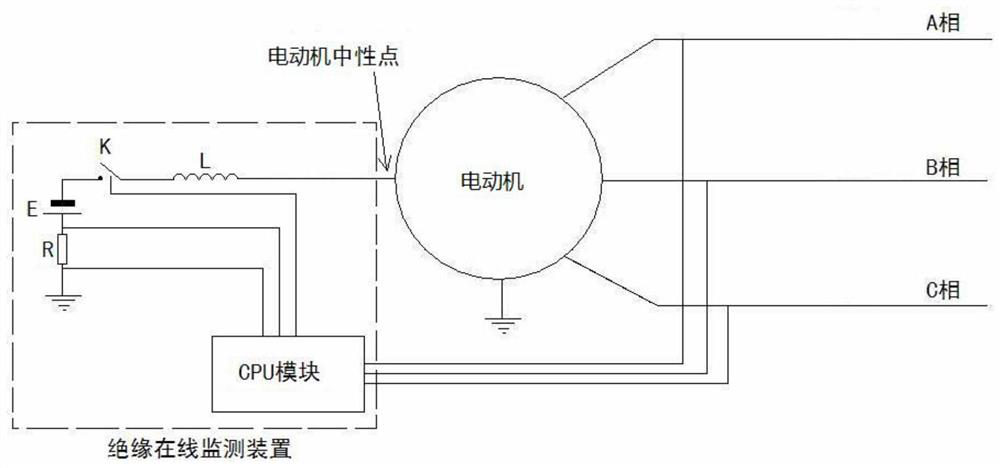

[0009] Such as figure 1 As shown, an on-line monitoring method for motor winding insulation, the equipment used includes: protective reactance L, relay K, constant voltage DC power supply E, sampling resistor R and insulation monitoring device; protective reactance L is connected to the neutral point outlet of the motor winding Above, the function is to prevent the relay K contact from being disconnected when the motor winding insulation monitoring device fails, causing the neutral point of the motor winding to be grounded for a long time through E and R; the output terminal of the protection reactance is connected to the normally open point of the relay K, The normally open point of the relay K is connected in series with the constant voltage DC power supply E and grounded through the sampling resistor R; the insulation monitoring device is responsible for collecting the exit voltage of the motor winding, which is used to decide when to close the contact of the relay K and col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com