A log cutting device suitable for mop bar production

A mop rod and log technology, which is applied in the forestry field, can solve problems such as waste of log materials, and achieve the effects of reducing the cost of raw materials and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

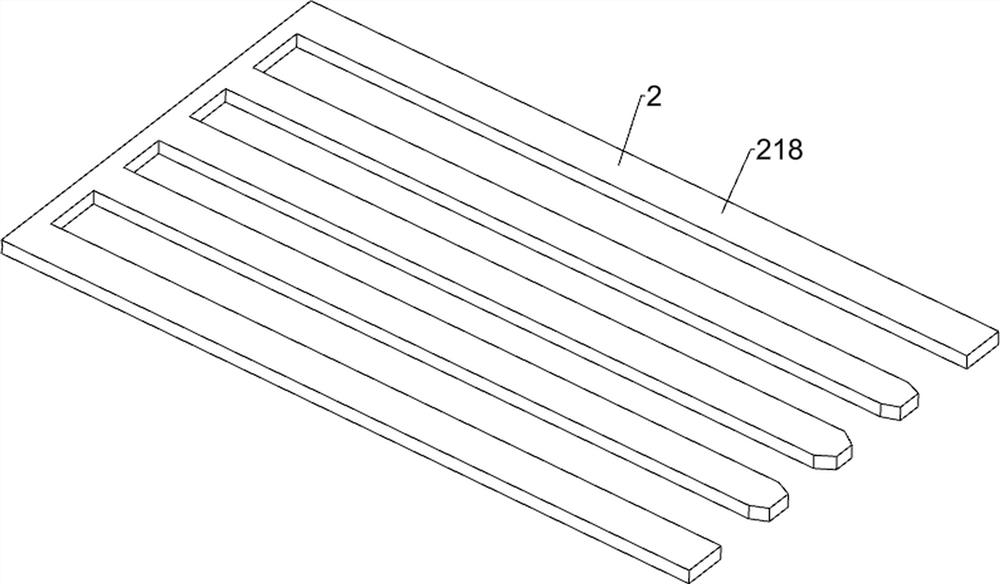

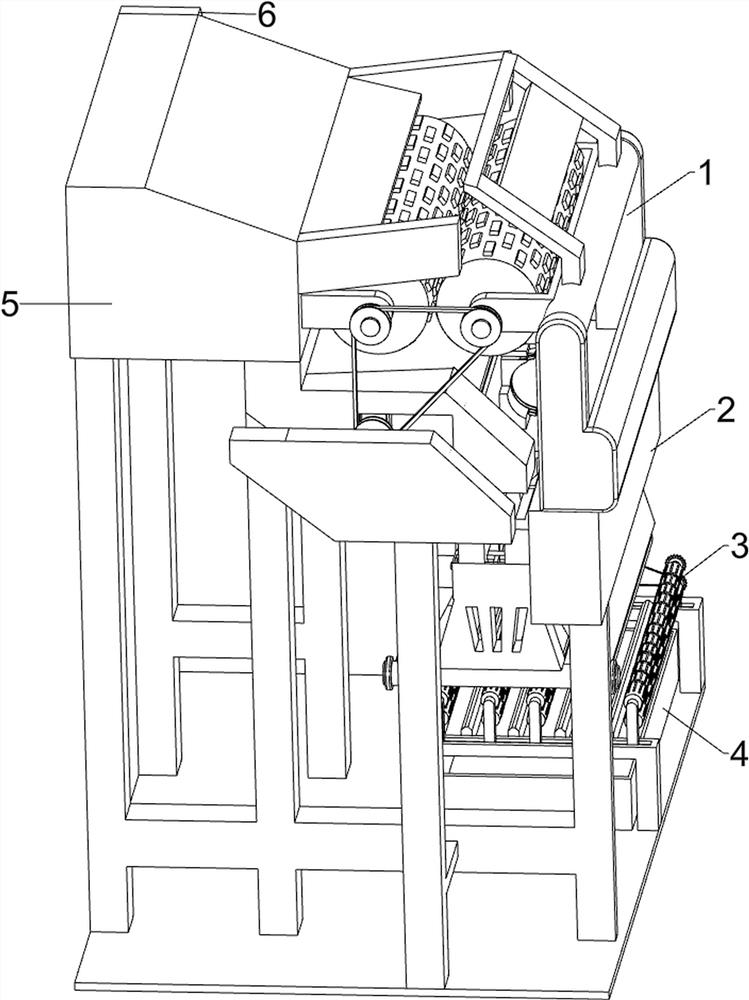

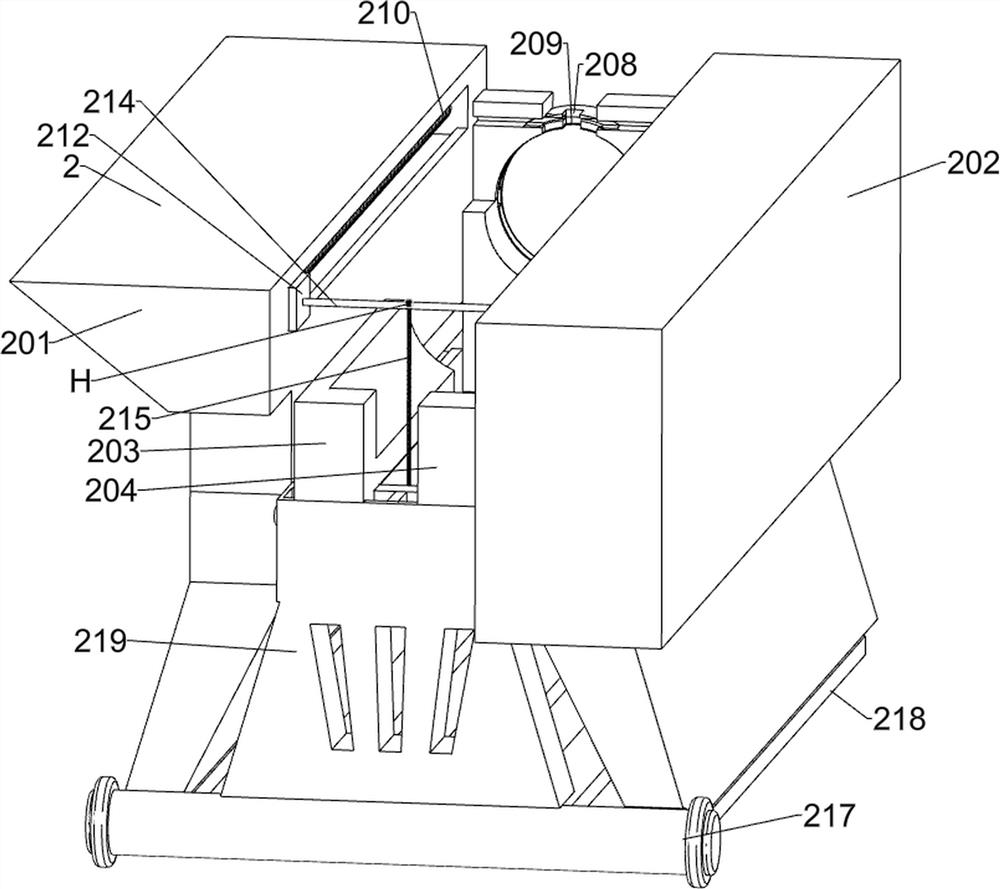

[0033] A log -cutting device suitable for the production of mop poles, such as Figure 1-13 It shows that there are pre -processing components, sub -cutting components, cutting components, collecting boxes, brackets, and console; pre -processing components connect to sub -cut components; Connect to the platform; connect to the cut component to the stand; connect the collection box to the bracket; the console is connected to the bracket.

[0034] First place it and keep the bracket stable, the external power supply, and the original wood processing work after regulating the console. The logs to be treated are rolled into the pre -processing component along the bracket platform. The component cuts the irregular shape of the log into a cylindrical wood with a unified size, and then the wood falls into the part -cut component. In the component, the cut component cuts four wooden strips into four cylindrical wooden sticks at the same time, and the four processed wooden sticks fall into ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap