Sectional type anoxic cracking method for household garbage

A domestic waste, segmented technology, applied in the field of segmented anoxic pyrolysis of domestic waste, can solve the problems of clean disposal of harmful substances dioxins, inability to crack domestic waste, and low output value of converted syngas, so as to eliminate harmful substances. Effects of dioxins, overcoming a lot of waste, prolonging the time of stay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

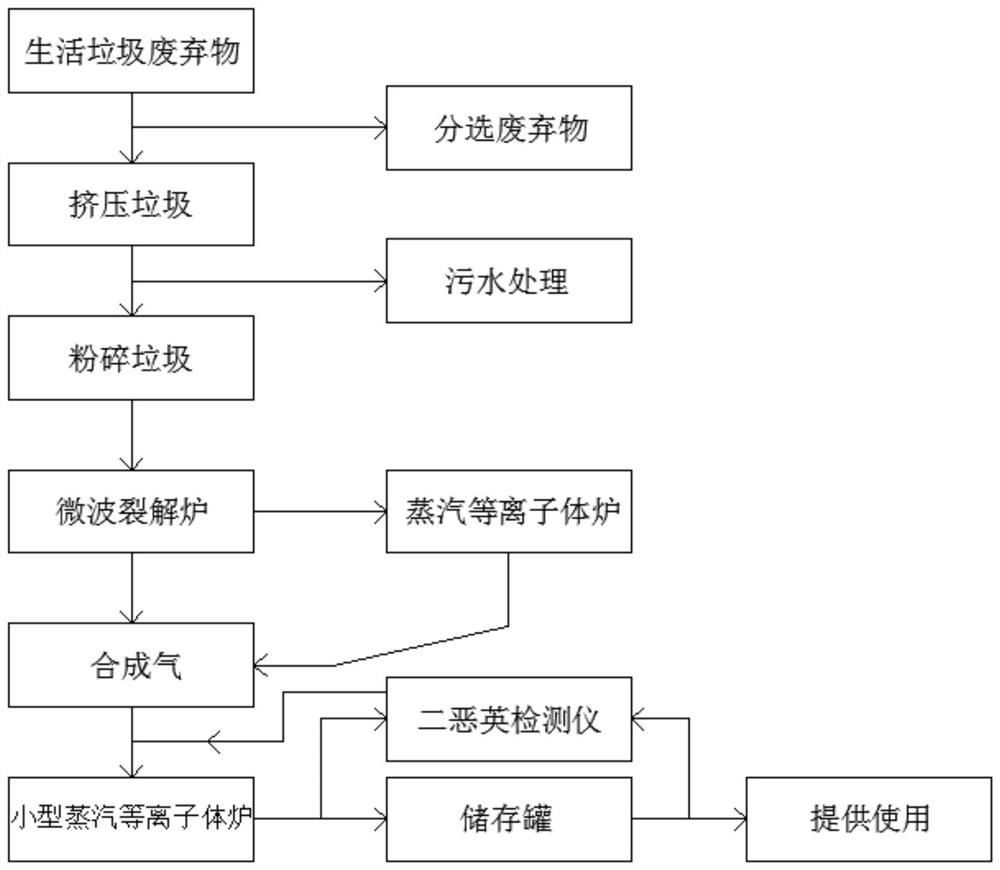

[0032] Combine below figure 1 Illustrate the specific embodiment of the present invention, a kind of subsection type anoxic pyrolysis method of household garbage, comprises pretreatment stage, pyrolysis stage and cleaning stage, and pyrolysis stage comprises the following steps:

[0033] S1: Transport the pulverized garbage prepared in the pretreatment stage to the microwave cracking furnace. The pulverized garbage should be stirred in advance to avoid agglomeration after entering the microwave cracking furnace; the pulverized garbage is cracked in an anoxic state with water vapor as the reaction medium , the ratio of the water vapor to be crushed is 1.33; the generated synthesis gas and ash are collected; the temperature in the microwave cracking furnace is controlled at 200-800°C;

[0034] S2: Transport the remaining ash and slag from the S...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap