An igniter

A technology of igniter and fire source, applied in the direction of combustion ignition, piezoelectric ignition, electrostatic ignition, etc., can solve problems such as danger and difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

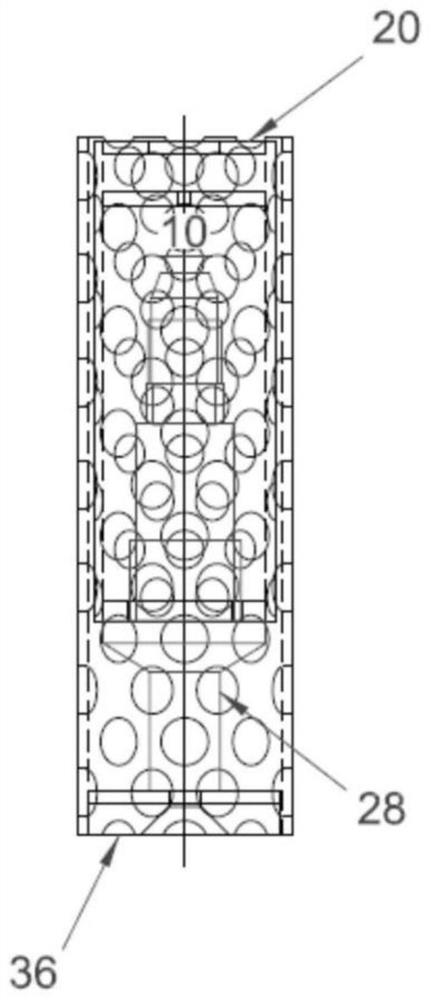

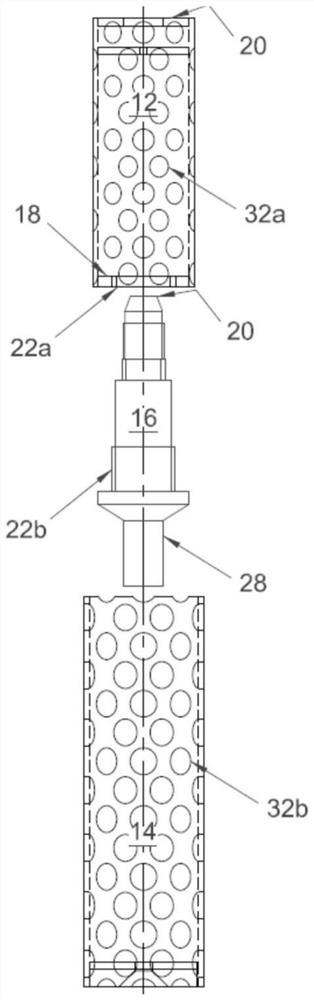

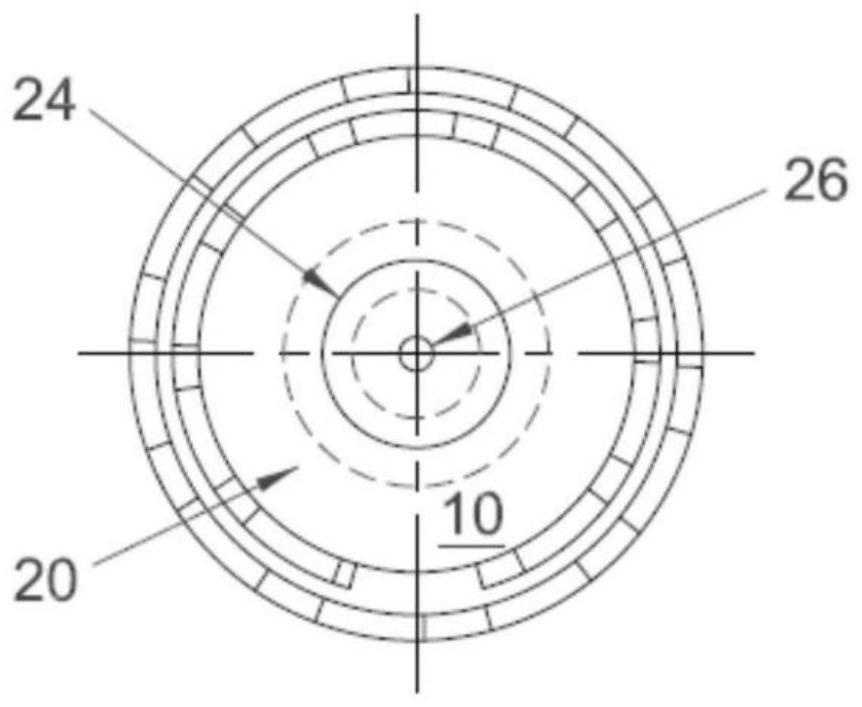

[0055] figure 1 , image 3 and Figure 4 One embodiment of the igniter assembly 10 of the present invention is shown, while figure 2 and Figure 6 An exploded view of the component parts of igniter assembly 10 is shown. figure 2 and Figure 6 Will be discussed in more detail in a later section.

[0056] The igniter assembly 10 may include: an inner holder in the form of an inner tubular member 12 ; an outer housing in the form of an outer tubular member 14 ; and a piezoelectric ignition source 16 . Inner tubular member 12 and outer tubular member 14 generally have a hollow cylindrical shape. While embodiments of the present invention define both the inner and outer tubular members comprising hollow cylindrical shapes, other tubular shapes having different cross-sections are contemplated, such as triangular, square and hexagonal.

[0057] Inner tubular member 12 and outer tubular member 14 are typically made of a heat resistant material such as mild steel. While embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com