A kind of transport robot for workshop and transport method

A robot and workshop technology, applied in transportation and packaging, motor vehicles, trolleys, etc., can solve the problems of easy accumulation of small foreign objects, easy to hinder the movement of other equipment, affecting the operation of rail cars, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

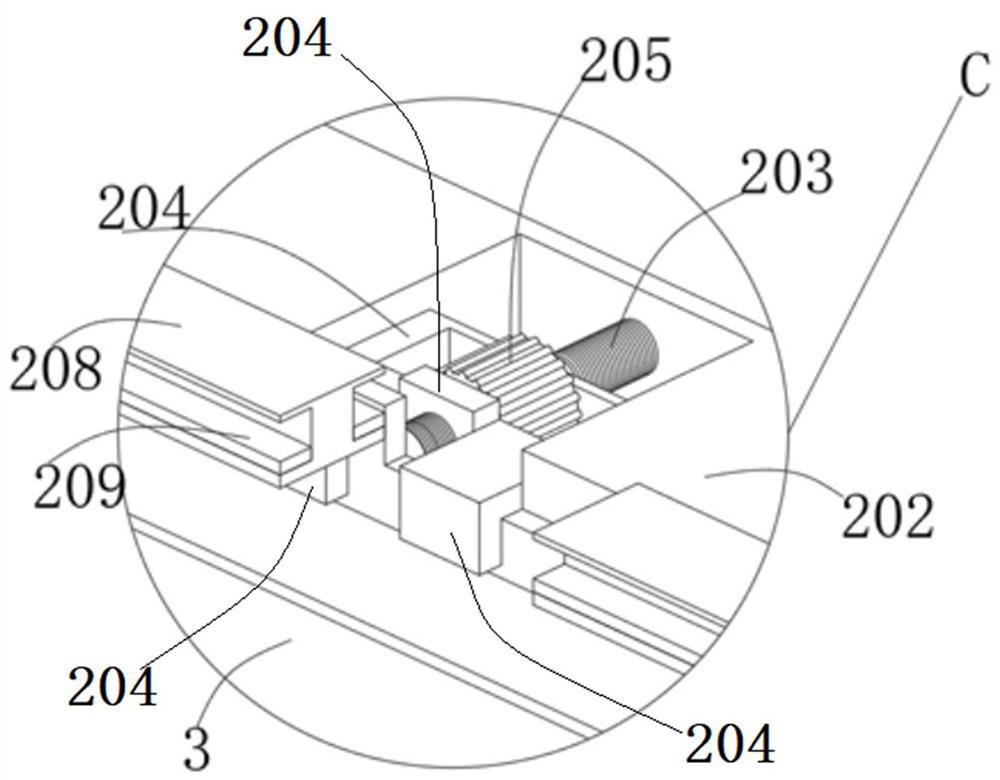

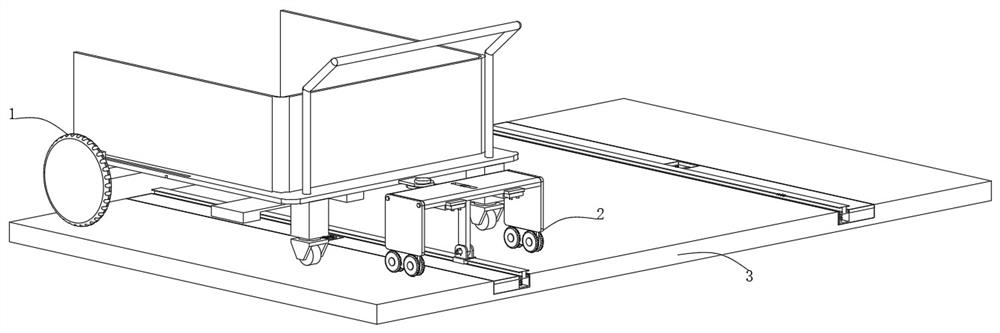

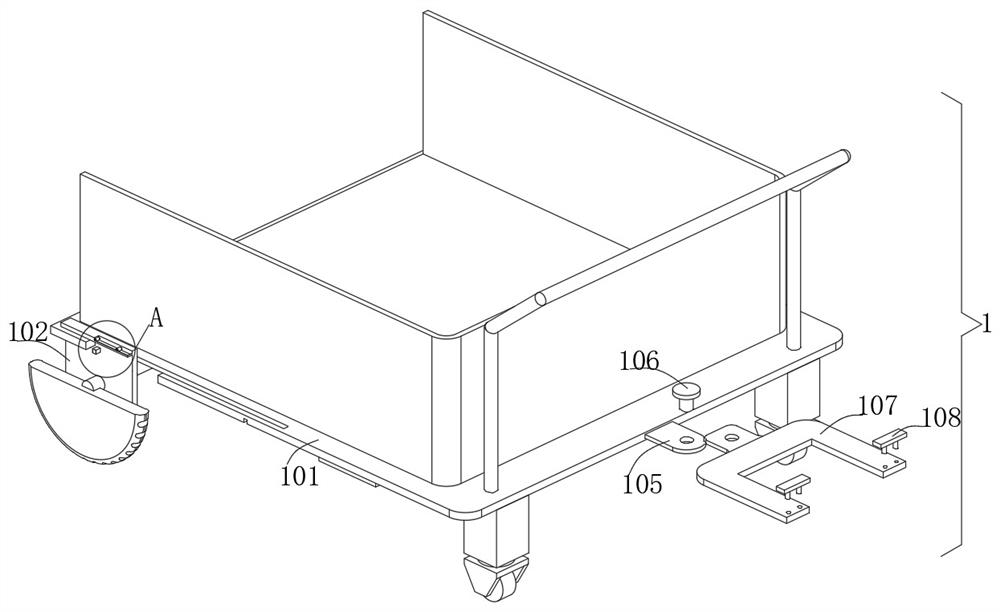

[0028] Embodiment 1, refer to Figure 1-9: A transport robot for workshop, including a storage mechanism 1, a guide mechanism 2 and a ground body 3, the guide mechanism 2 is arranged on the top of the ground body 3, the storage mechanism 1 is also arranged on the top of the ground body 3, and the guide mechanism 2 includes two installations Frame 202 and moving frame 210, the establishment of the installation frame 202 is convenient for the installation and setting of other functional components of the equipment, the establishment of the mobile frame 210 is convenient for the installation and setting of other functional components of the equipment, and the top center of each installation frame 202 is provided with an installation slot. The establishment of the installation groove is convenient for the installation and setting of the installation frame 202. The threaded rods 203 are fixedly connected between the two sides of each installation groove relative to the center of the...

Embodiment 2

[0029] Embodiment 2, refer to Figure 2-9 : the outer surface of each support frame 204 slides through to the bottom of the corresponding guide rail 208 , the bottom center of the moving frame 210 is fixedly connected to both sides with the connecting frame 211 , and the bottom end of each limit rod 216 slides through the limit tube 213 On the inner bottom surface, the inner surface walls on both sides of each mounting frame 202 are fixedly connected with limit bars 209 near the top edge. The outer surfaces on both sides of the vehicle body 101 are provided with a set of positioning openings on one side of the corresponding adjustment groove, and each set of positioning openings has a total of There are two. The outer surfaces of the two sides of the movable frame 102 are located inside the two positioning openings, and the adjustment blocks 103 are fixedly connected. The top of the connecting frame 107 is slidingly embedded with limit bolts 108 near the edges of both ends. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com