High-rail corridor elevator walking mechanism

A technology for corridor elevators and walking mechanisms, which is used in elevators, lifts, transportation and packaging in buildings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

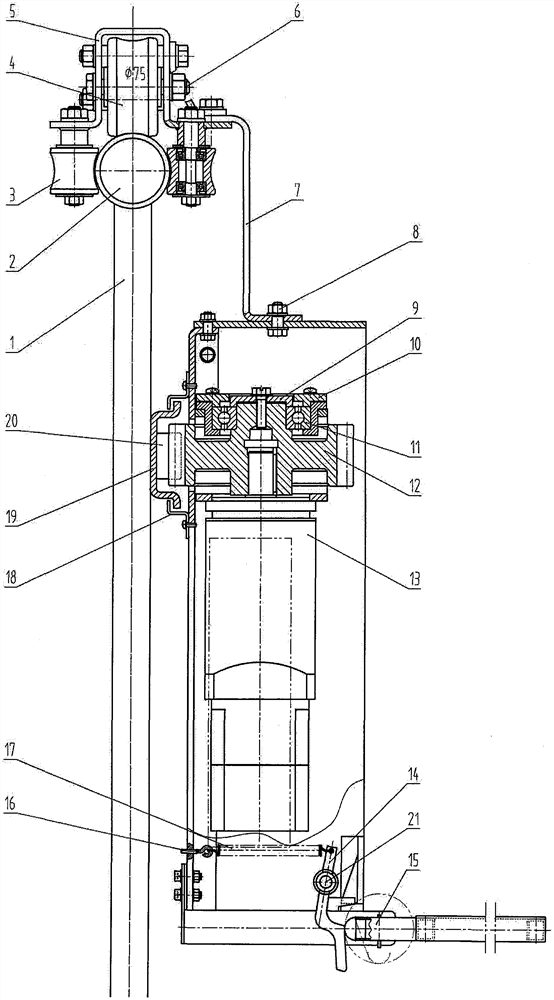

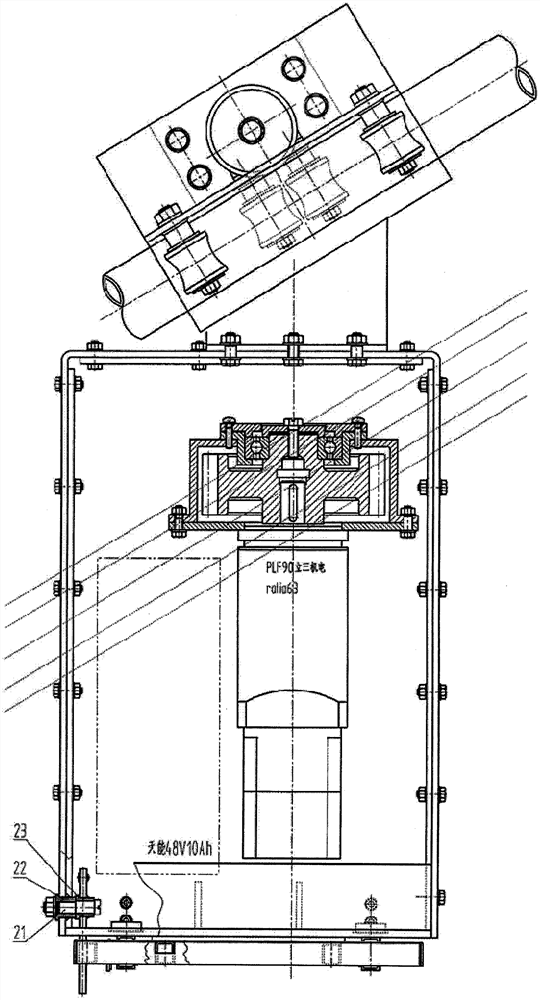

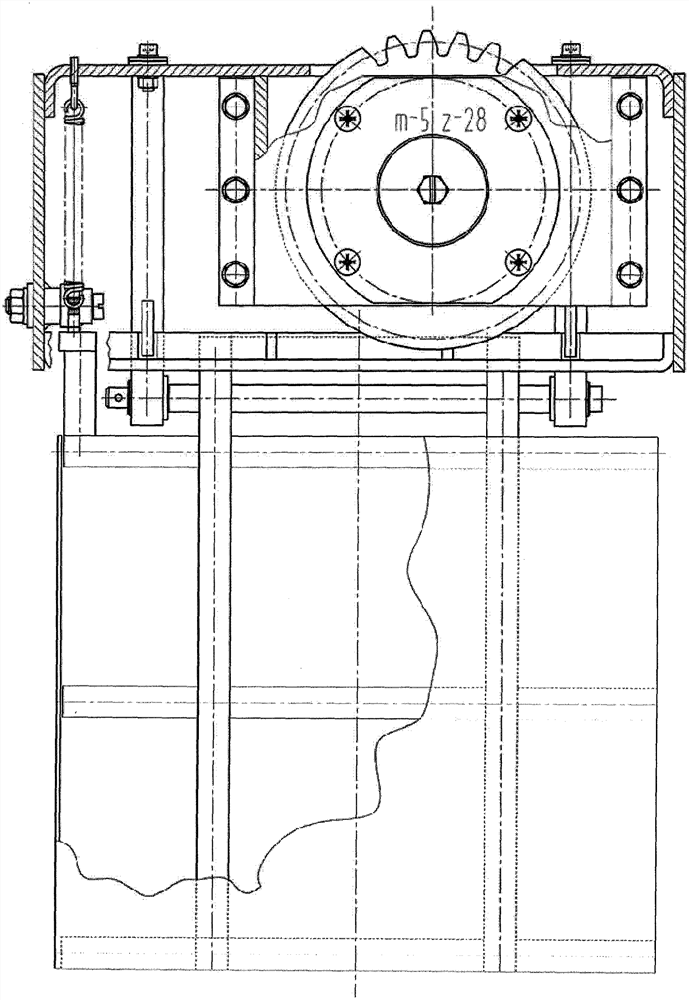

[0016] The invention includes a bearing wheel assembly, a frame, a power assembly and a pedal mechanism. like figure 1 , the load-bearing wheel assembly includes a wheel frame 5, load-bearing wheels 4 and 4 guide wheels 3. like figure 2 , the cross-section of the wheel frame 5 is shaped like a door frame, and the center positions of the two vertical plates of the wheel frame 5 are provided with concentric holes, and the center line is a horizontal line. The load-bearing wheel 4 is located in the middle of the wheel frame 5, and the load-bearing wheel shaft is installed in the concentric hole and fastened with a nut 6. The lower end of the vertical plate of the wheel frame is bent 90° to the outside as the guide wheel mounting plate. Two shaft holes are respectively arranged on the mounting plate, and its axis is perpendicular to the axis of the guide rail 2. The wheel shafts of the 4 guide wheels 3 are respectively contained in the shaft holes and fastened with nuts. lik...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com