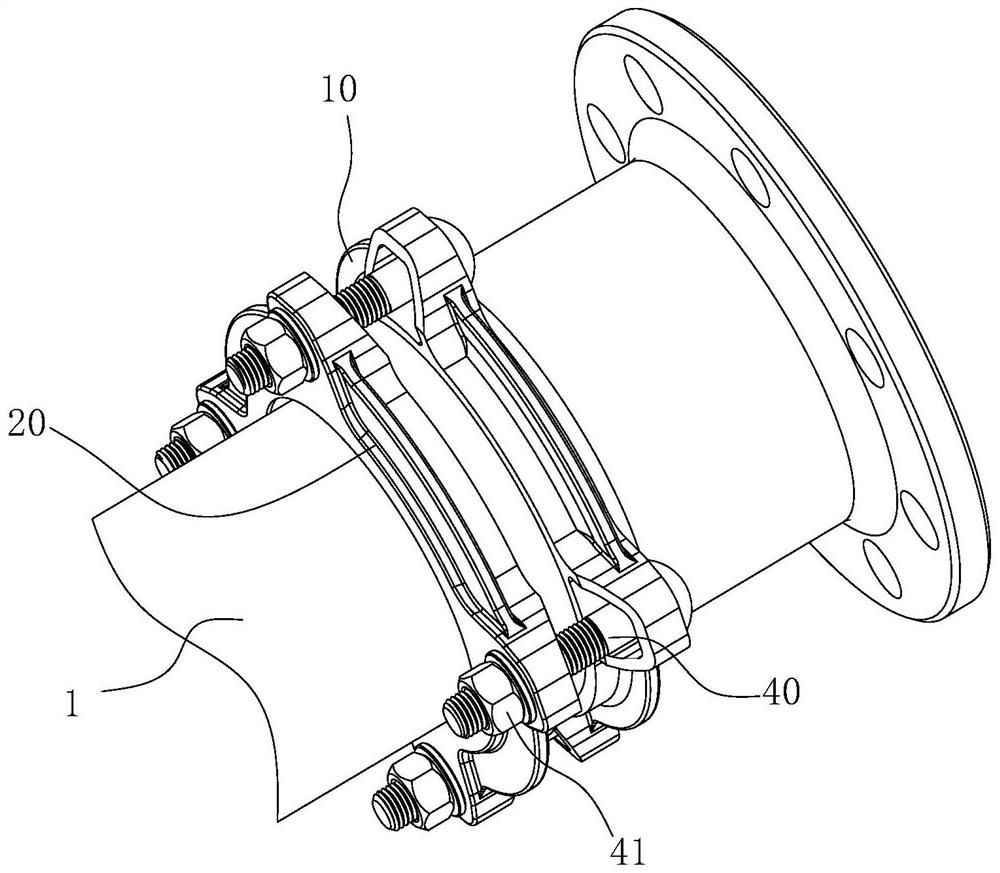

Pipe connecting device

A connecting device and pipeline technology, which is applied in the direction of flange connection, sealing surface connection, pipe/pipe joint/pipe fitting, etc., can solve the problem that the elastic sealing ring cannot form a sealing ring, the sealing effect is poor, and the elastic sealing ring is prone to aging and failure And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

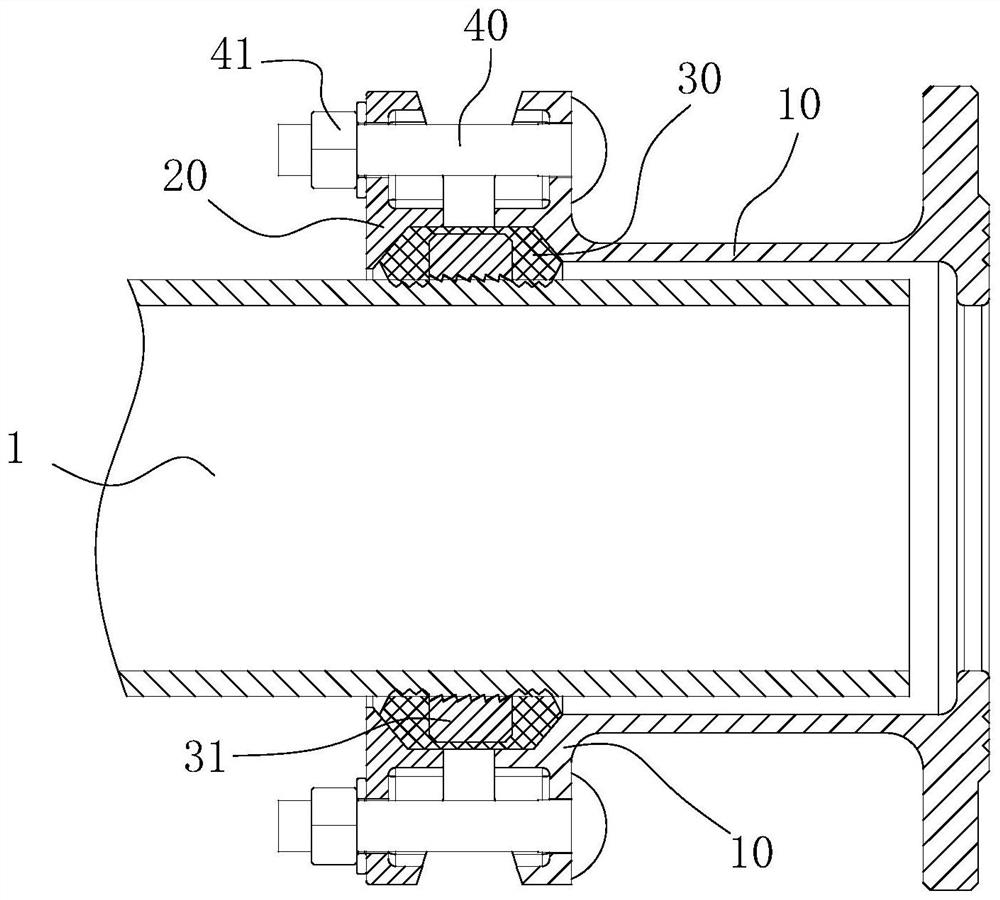

[0016] Embodiment one: if figure 2 As shown, the locking teeth 31 are arranged in the middle of the elastic sealing ring 30, the distance between the connecting sleeve 10 and the pressing sleeve 20

Embodiment 2

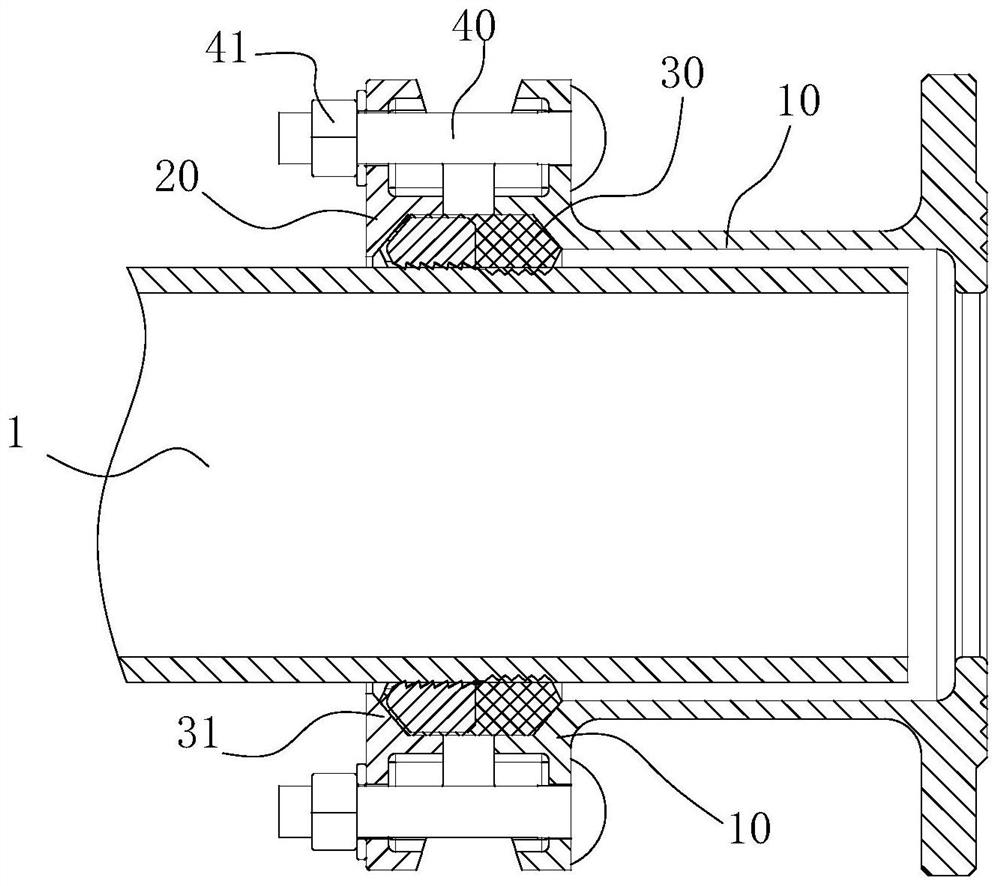

[0017] Embodiment two: if image 3 As shown, the locking teeth 31 are arranged at the half of the elastic sealing ring 30 close to the pressure sleeve, and the axial dimension of the locking teeth 31 is smaller than the width of the inner ring of the elastic sealing ring 30 . In this way, the width of the sealing surface is further increased to improve the sealing effect.

Embodiment 3

[0018] Embodiment three: as Figure 4 As shown, the cross section of the locking teeth 31 is in the shape of "I", and the outer ring of the "I" shape is embedded in the outer ring of the elastic sealing ring 30 . The "I" shape effectively ensures its structural strength and the exposed "I" shaped outer ring can more effectively withstand the gap between the connecting sleeve 10 and the pressing sleeve 20 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com