Clamping device for rapidly clamping end socket of pressure container

A technology for clamping pressure and container heads, applied in chucks, manufacturing tools, manipulators, etc., can solve problems such as head deformation and increase the risk of head welding defects, achieve uniform force and reduce head deformation. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific technical solutions of the present invention are further described below, so that those skilled in the art can further understand the present invention, but do not limit the rights thereof.

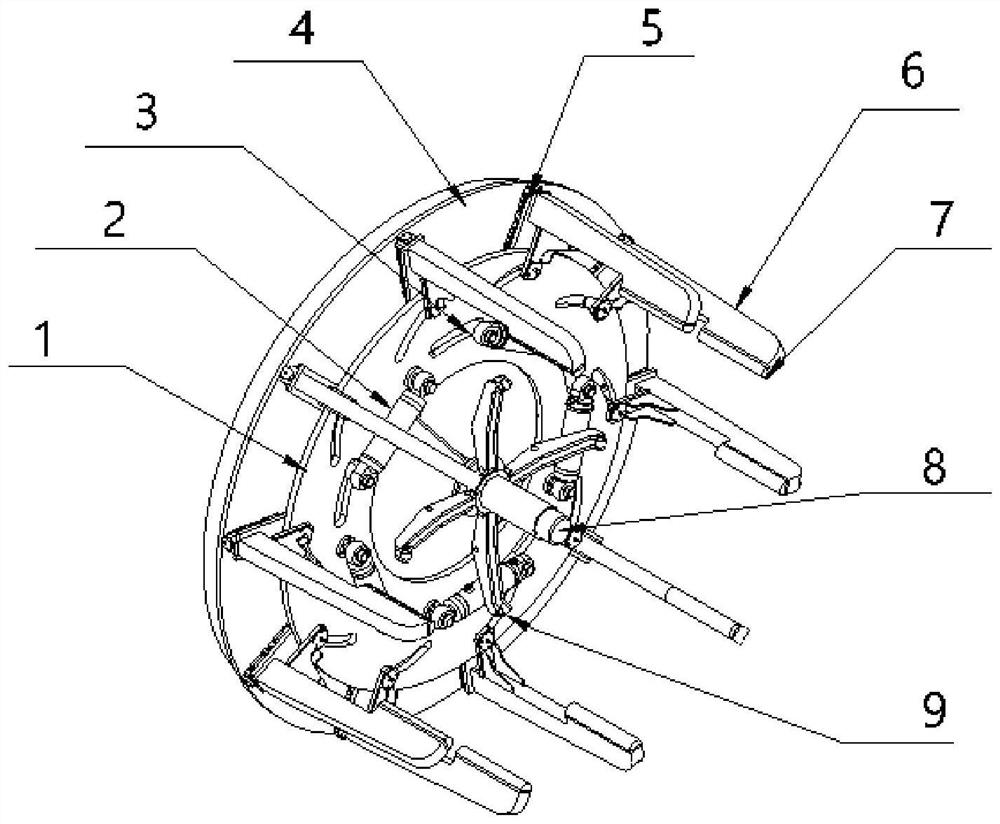

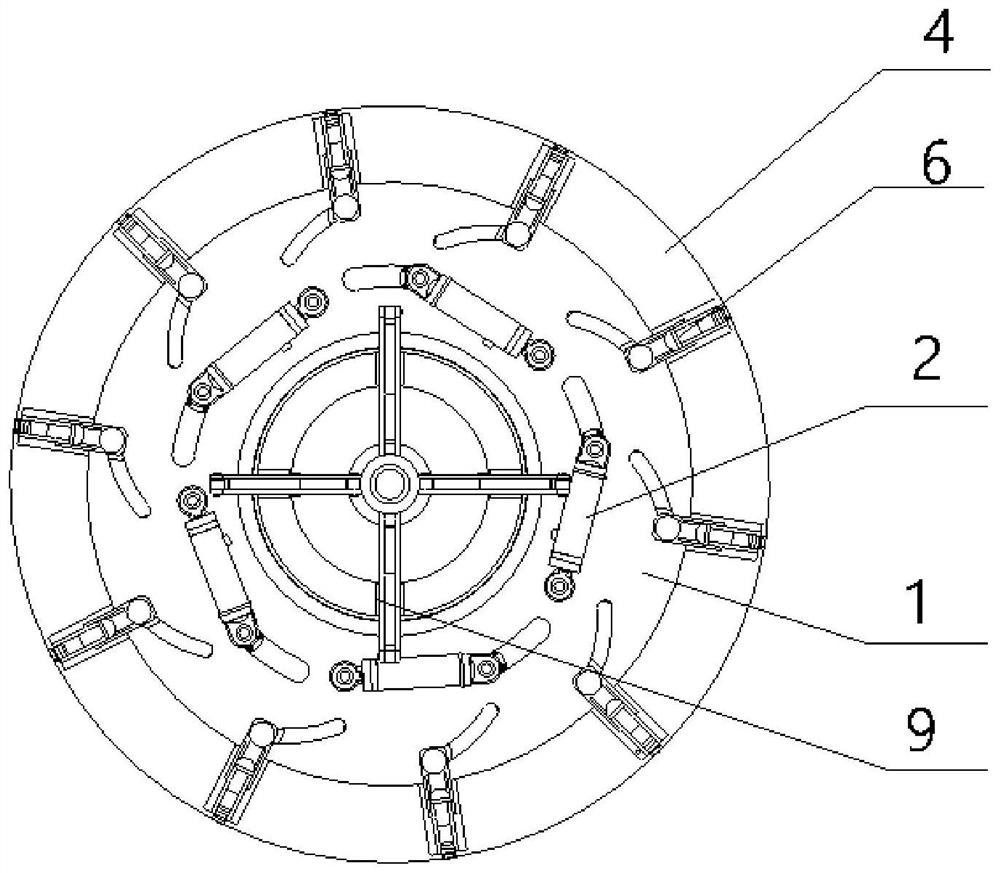

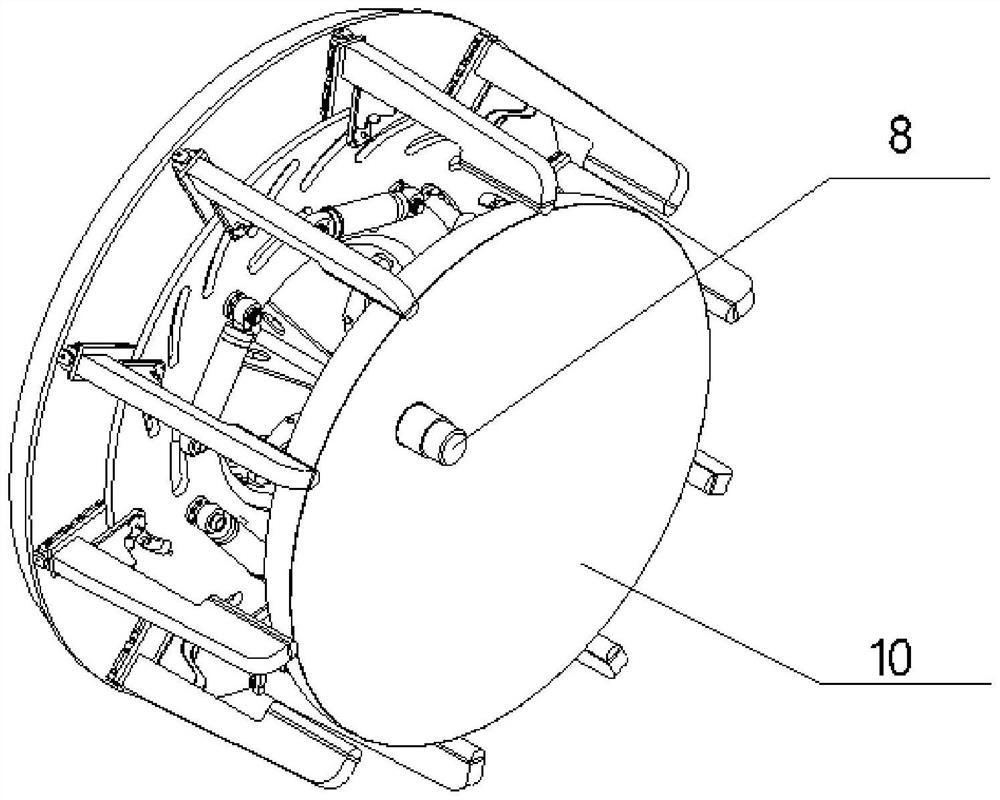

[0018] refer to Figure 1-Figure 3 , a clamping device for quickly clamping the head of a pressure vessel, including a chassis base, a turntable and a number of claws, the chassis base and the turntable are arranged concentrically, the turntable is rotated and installed on the chassis base, and the center position of the chassis base is installed There is a head positioning shaft, and a drive mechanism that drives the turntable to rotate is installed on the turntable; a number of slideways are radially installed on the upper surface of the chassis base, the jaws are installed on the slideways, and the jaws are provided with slideways. A guide pin shaft arranged in parallel, the turntable is provided with a guide groove that cooperates with the guide pin and pulls the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com