Rice seedling raising device with an automatic sowing function

A seedling raising device and rice technology, which is applied in the field of plant seedling raising, can solve the problems of large manpower, difficulty in sweeping mud, uneven seed distribution, etc., and achieve the effect of uniform arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

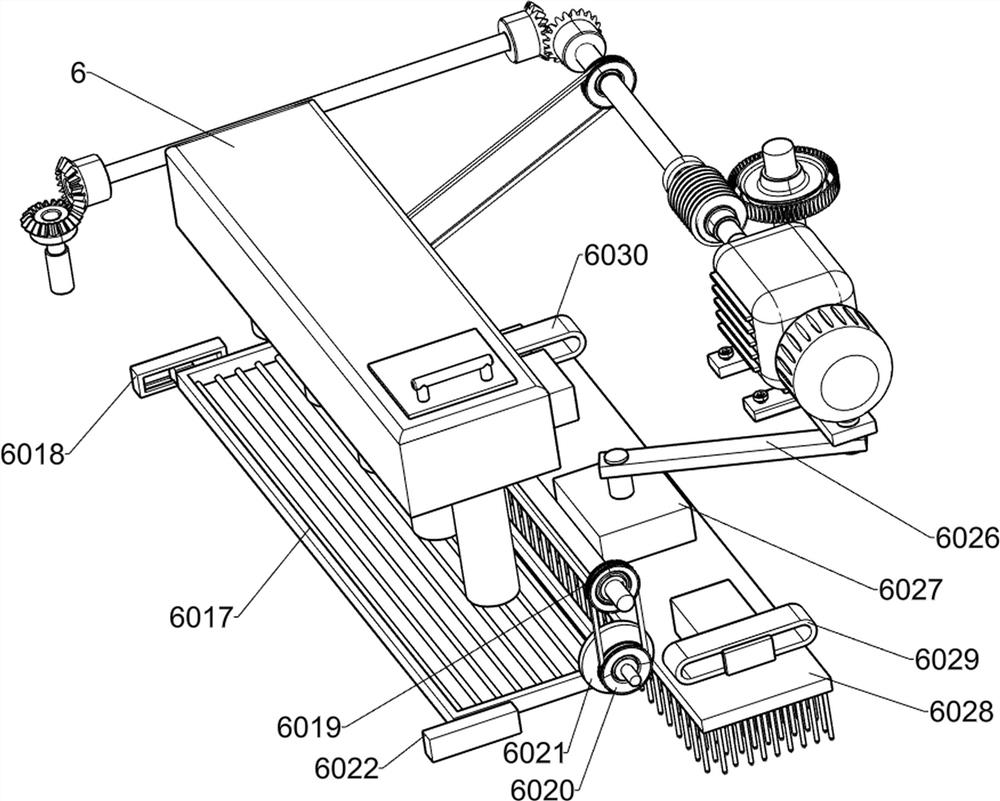

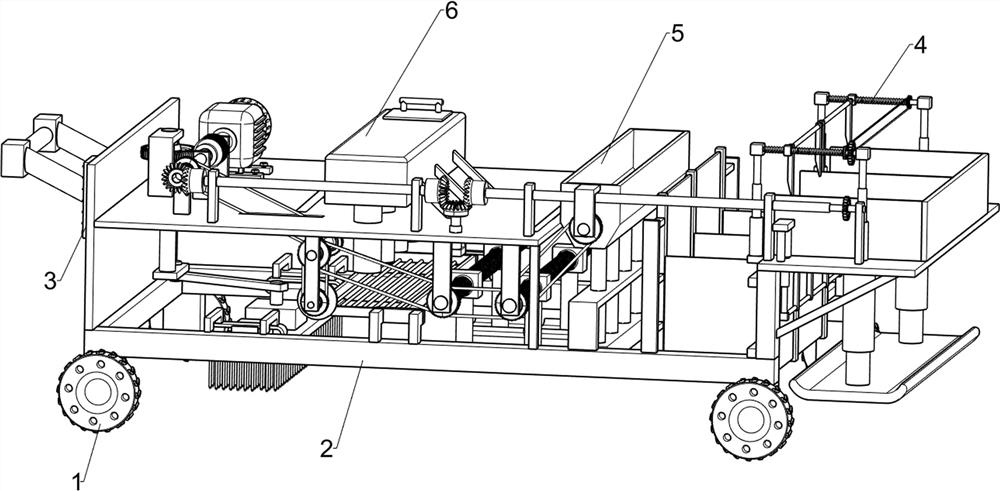

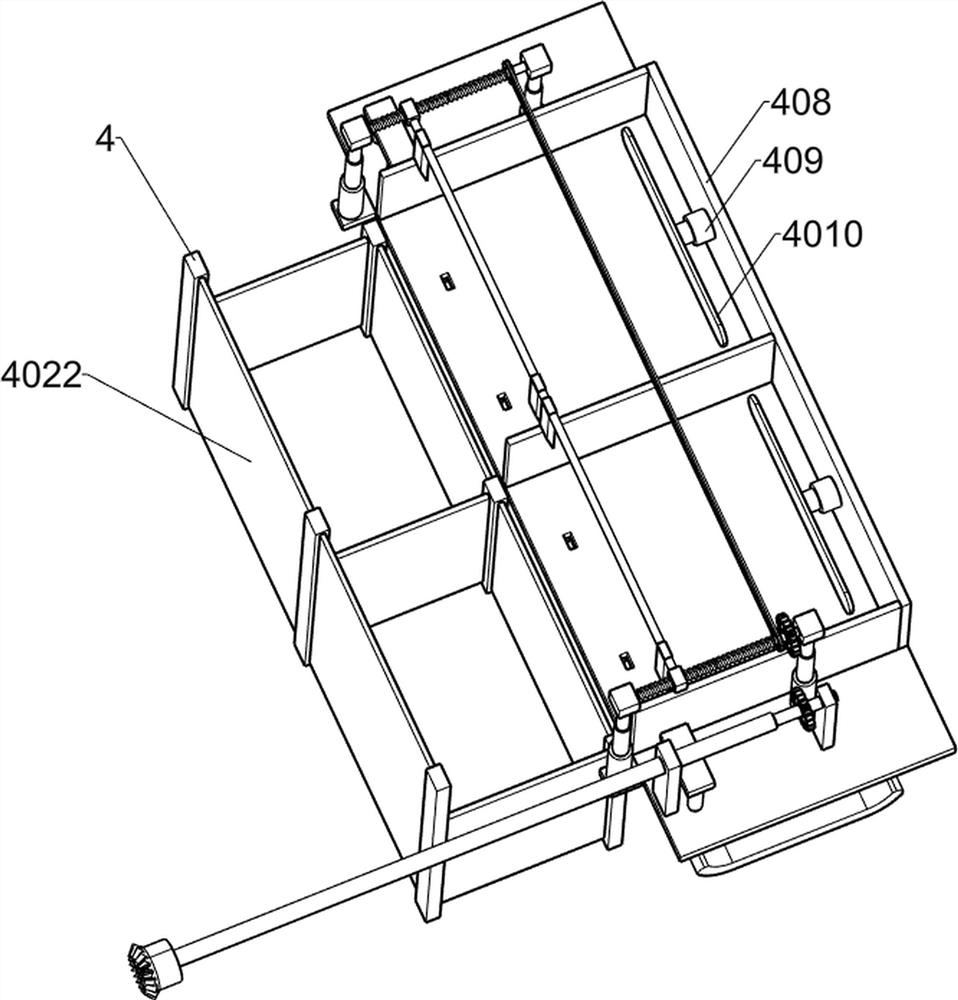

[0029] A rice seedling raising device for automatic seeding, such as Figure 1-10 As shown, it includes a wheel 1, a support chassis 2, a controller 3, a seedling raising board placement system 4, a mud feeding system 5 and a seeding system 6; the four diagonal corners of the support chassis 2 are respectively provided with wheels 1; the support chassis 2 is connected with the controller 3; the seedling raising board placement system 4, the mud feeding system 5 and the seeding system 6 are sequentially arranged above the supporting chassis 2; the mud feeding system 5 is connected with the seeding system 6.

[0030] Before the device is in operation, push the device to the seedling field, connect the battery externally, control the controller 3 to start the device, check the running transmission between the systems, and close the device after confirming that it is correct; put the germinated seeds into the seeds in the sowing system 6 The storage box 6011 puts the soil into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com