Poultry breeding device and method

A poultry and chamber technology, applied in the field of poultry breeding, can solve the problems of large temperature difference, waste of heat, sick goslings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

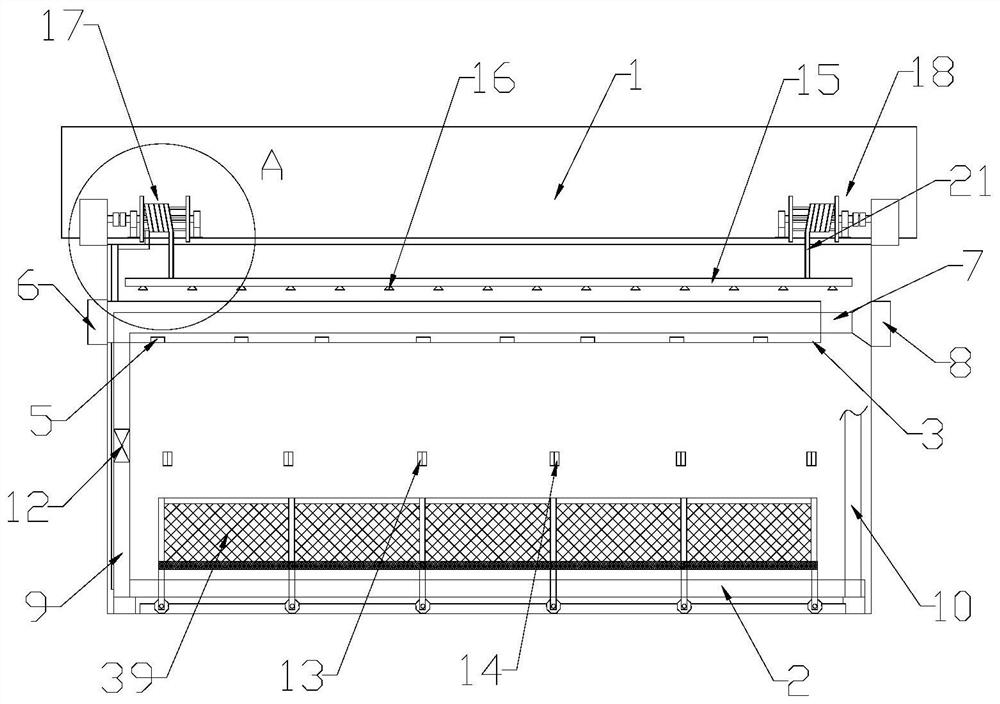

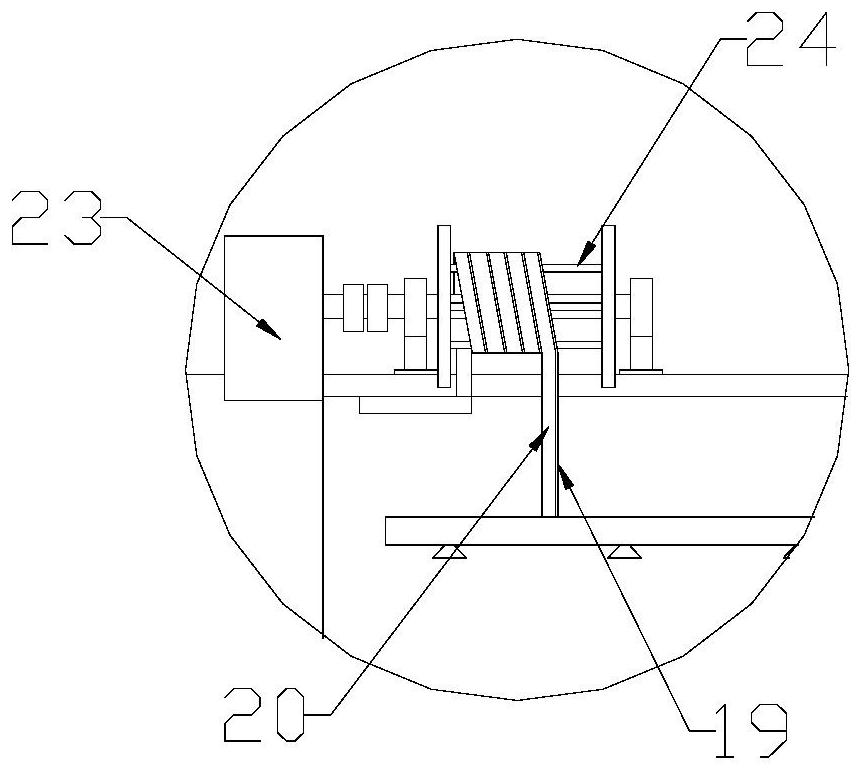

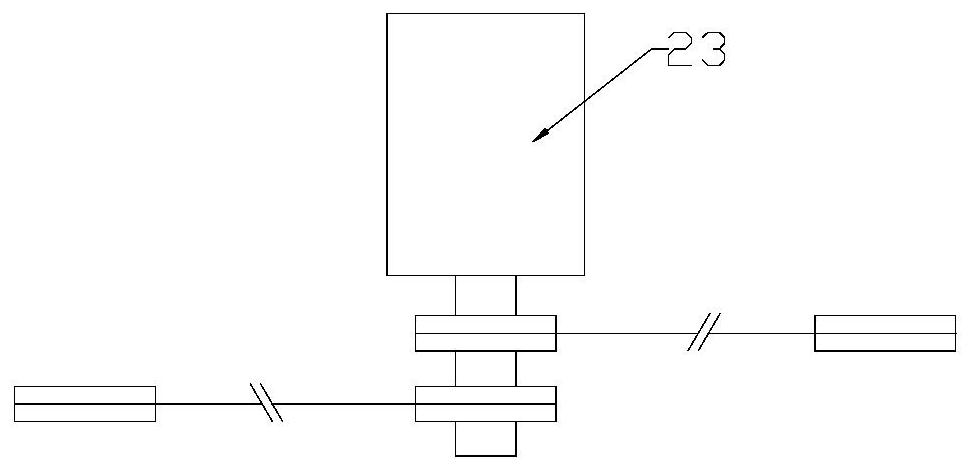

[0031] Such as figure 1 , 5 As shown in and 6, a poultry breeding device includes a chamber body 1, and the lower end of the chamber body 1 is provided with 2 rows of feeding units at intervals, and a ventilation duct 2 is fixed below each row of feeding units, and a heating mechanism is installed in the ventilation duct 2 , the heating mechanism can be an electric heater, etc., and the two side walls in the chamber body 1 are respectively fixed with an exhaust channel 3 and a second air inlet duct 4, and the exhaust channel 3 is provided with several exhaust outlets 5, and the exhaust outlet The first one-way valve is installed at 5 places, and one end of the exhaust pipe is a closed end, and the other end is connected to the air outlet, and an exhaust fan 6 is installed at the air outlet.

[0032] The first air inlet duct 7 is fixed in the exhaust passage 3, and one end of the first air inlet duct 7 passes through the closed end to be connected with the air inlet, and the a...

Embodiment 2

[0043] This embodiment is basically the same as Embodiment 1, the difference is that, as Image 6 As shown, both ends of the ventilation pipe 2 are provided with a vent 34 communicating with the interior of the chamber 1, and the vent 34 is provided with an openable gate 35, and the gate 35 is in sealing contact with the vent 34, and the gate 35 can be pneumatically operated. A telescoping rod or an electric telescoping rod controls opening and closing. The gate 35 is in the normally open state, and the indoor air is heated by the heating mechanism to ensure the indoor temperature. In order to ensure that the indoor temperature is uniform, a fan can also be installed indoors to accelerate the flow of air; when the room needs ventilation, the gate 35 is closed, and the rest of the steps Same as embodiment one.

Embodiment 3

[0045] This embodiment is basically the same as embodiment one or two, the difference is that, as Image 6 As shown, each row of feeding units includes a plurality of feeding compartments 39, and the heating mechanism includes a heating inlet pipe 36, which is connected to the steam oven, and the heating inlet pipe 36 is arranged between adjacent feeding units, and the ventilation duct 2 is provided There are heating fins 37 corresponding to the feeding compartments 39 one-to-one. The side of the ventilation duct 2 away from the heating inlet pipe 36 is provided with a cooling outlet pipe 38. One end of the heating radiator 37 is connected to the heating inlet pipe 36, and the other end is connected to the cooling pipe 36. Outlet pipe 38 is connected. The hot steam enters the heating radiator 37 through the heating inlet pipe 36 for heat exchange, and the cold water is discharged through the cooling outlet pipe 38. By setting the heating radiator 37 corresponding to the feedin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com