Folding control surface assembling method

An assembly method and technology for folding rudders, which are used in manufacturing tools, hand-held tools, etc., can solve the problems of peeling off the protective coating on the surface of the rudder surface, unable to find the mounting holes of the rudder surface, and difficult to meet the design requirements, so as to reduce the number of equipment. , Excellent assembly quality and use effect, the effect of improving assembly accessibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

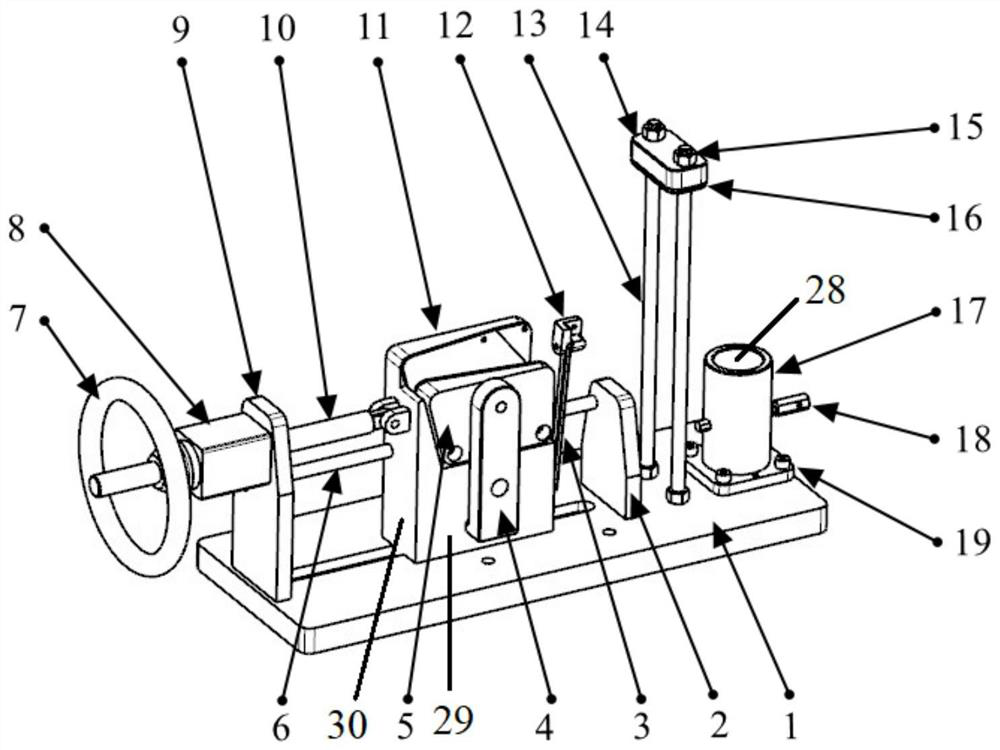

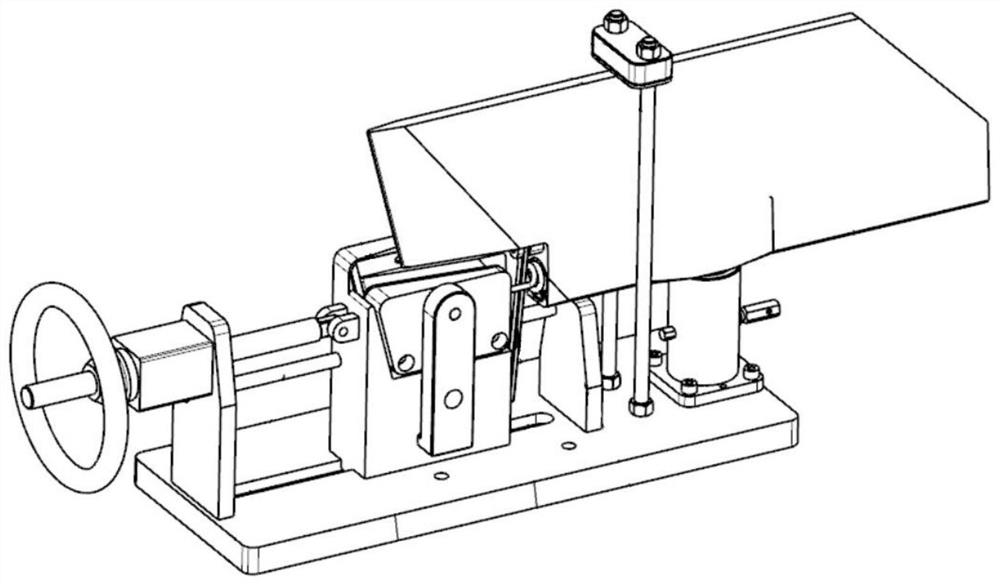

[0078] A specific embodiment of the present invention discloses a rudder surface assembly tool for assembling the front section of the rudder surface and the rear section of the rudder surface. Such as figure 1 As shown, the rudder surface assembly tooling includes a first positioning clamping structure, a second positioning clamping structure, a torsion spring alignment structure and an orientation drive mechanism.

[0079] The structure and function of each part of the rudder surface assembly tool are described in detail below.

[0080] The first positioning and clamping structure is used for positioning and clamping the front section of the rudder, and provides a basis for subsequent structures. The first positioning clamping structure includes a positioning clamping assembly and a first clamping part.

[0081] Such as figure 1 As shown, the positioning and clamping assembly includes a base 1 , a mounting seat 17 , a positioning pin 18 and a screw 19 . The mounting base...

Embodiment 2

[0102] Another specific embodiment of the present invention discloses a rudder surface assembly method, such as Figure 7 As shown, this assembly method is suitable for the assembly process of the folded structure rudder surface containing torsion spring elements with large torque. Specifically, the assembly method includes the following steps:

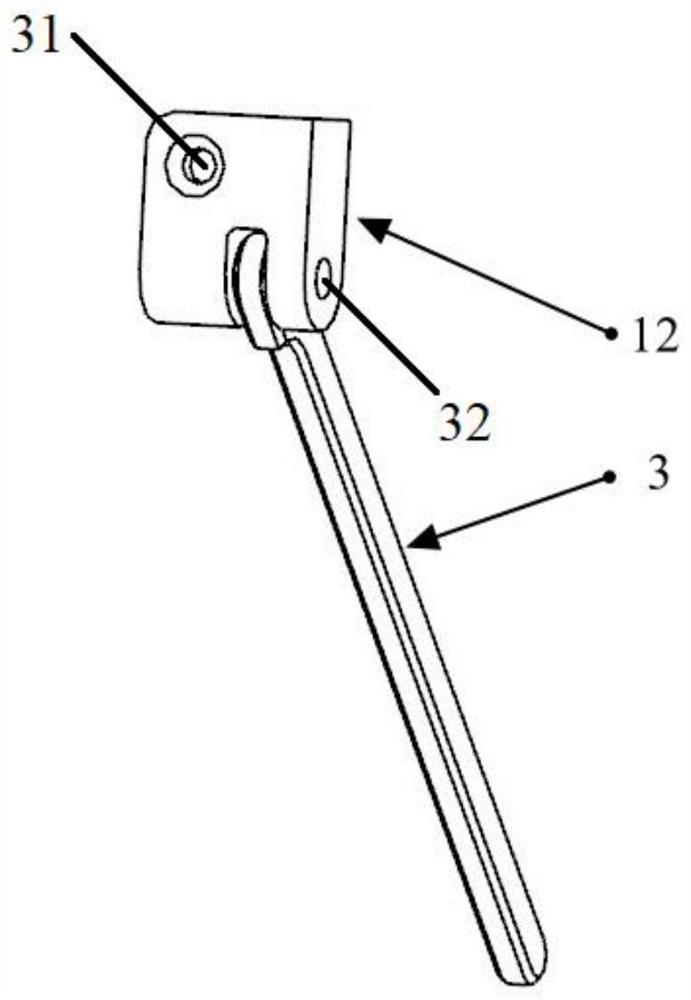

[0103] (1) Insert the rotating shaft 27 of the front section of the rudder into the shaft hole of the mounting seat 17, adjust the angular position of the front section of the rudder, and insert the positioning pin 18 to constrain it. During the process of inserting the front section of the rudder, pay attention to avoiding the screw rods 13 on both sides to prevent the screw rods from rubbing rudder surface coating;

[0104] (2) Install the upper platen 16 on the screw rods 13 on both sides, and fix it by nuts 15. Before installation, check whether the rubber pad 14 on the bottom surface of the upper platen 16 exists, and install it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com