Laser automatic obstacle avoidance and autonomous driving meal delivery robot

A food delivery robot and automatic obstacle avoidance technology, applied in the direction of manipulators, manufacturing tools, etc., can solve problems such as odor accumulation, shelf contamination, spillage, etc., and achieve the effects of umami protection, stability assurance, and vibration mitigation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

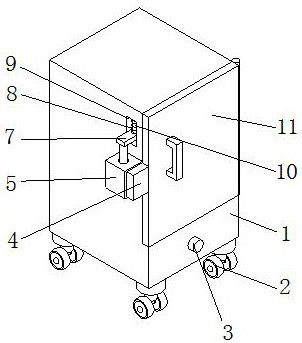

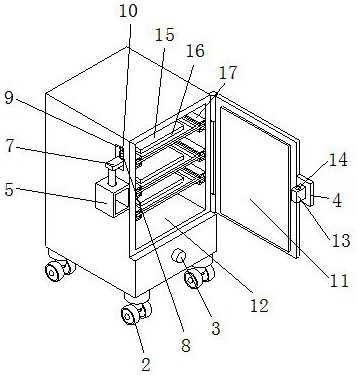

[0031] see Figure 1-Figure 3 , the present invention provides a technical solution: a laser automatic obstacle avoidance and autonomous driving food delivery robot, including a robot body 1, the robot body 1 is an existing structure and will not be described in detail here, the interior of the robot body 1 is a hollow structure, The inside of the robot body 1 is provided with a power supply, a power device and a control system, and the bottom of the robot body 1 is provided with a universal wheel 2, which is an existing structure. The power device can make the universal wheel 2 rotate, and then make the robot body 1 move, and the robot body 1 can be programmed through the external control system. The front side of the robot body 1 is fixedly connected with the sensor 3, and the sensor 3 is The existing structure will not be described too much here. The sensor 3 is connected to the power supply inside the robot body 1 to work. The robot body 1 can sense whether there is an obs...

Embodiment 2

[0034] see Figure 4-Figure 5 , on the basis of Embodiment 1, a chute 23 is provided on the upper surface of the slide rail 17, and a support block 18 is slidably connected to the inside of the chute 23, and the support block 18 can move up and down inside the chute 23, and the chute The upper surface inside the 23 is fixedly connected with a first support block 22. The interior of the first support block 22 is a hollow structure. On the inner upper surface, a plurality of first support blocks 22 are provided with the same structure, the upper surface inside the first support block 22 is fixedly connected with a third spring 24, and the bottom end of the third spring 24 is fixedly connected with a second support block 25, the surface of the second support block 25 is slidingly connected with the inside of the first support block 22, the second support block 25 can slide up and down inside the first support block 22, and the top of the second support block 25 is connected with ...

Embodiment 3

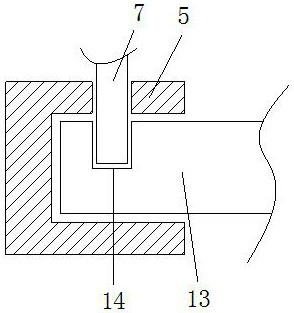

[0037] see Figure 1-Figure 3 , on the basis of Embodiment 1, the left side of the robot body 1 is fixedly connected with a second fixed block 5, the inside of the second fixed block 5 is a hollow structure, and the left side of the robot body 1 is provided with a moving groove 9, and the moving groove 9 The inside of the moving groove 9 is fixedly connected with a positioning shaft 10, and the inside of the moving groove 9 is slidably connected with a fixed rod 7. The fixed rod 7 is in an inverted L shape, and the fixing rod 7 can move up and down inside the moving groove 9. The inside of the rod 7 transverse rod extends to the outside of the fixed rod 7, the inside of the fixed rod 7 horizontal rod is slidingly connected with the surface of the positioning shaft 10, the fixed rod 7 can move up and down on the surface of the positioning shaft 10, the fixed rod 7 horizontal rod The top of the top is fixedly connected with the first spring 8, the top of the first spring 8 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com