Chemical quantitative filling machine

A filling machine, chemical technology, applied in the chemical field, can solve the problems of different rates, inaccurate filling amount, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

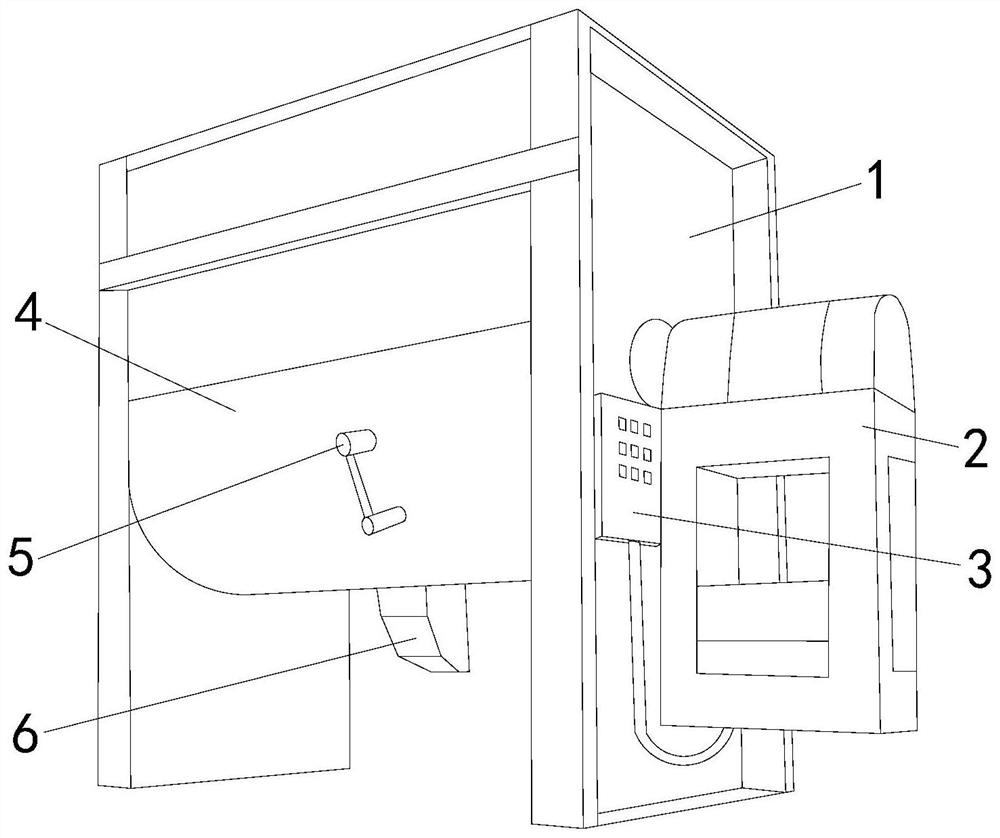

[0024] see figure 1 , the present invention provides a chemical quantitative filling machine, the structure of which includes: a chassis frame 1, a power box 2, a control panel 3, a filling box 4, a stop valve 5, and a liquid outlet 6, and the side of the chassis frame 1 The power box 2 and the control panel 3 are connected. The filling box 4 is located in the chassis frame 1 and is connected with a stop valve 5. The liquid outlet 6 is located at the bottom of the chassis frame 1 and communicates with the filling box 4. The chassis frame 1 The filling box is connected by two plates of equal size. 4 forms the frame structure of the filling machine, and its bottom is at the same level as the ground. As a communication carrier between the power box 2 and the filling box 4, the power lines in the two are connected to each other, relying on the power supply of the power box 2, the filling box 4 has the kinetic energy to realize chemical quantification and process raw material resi...

Embodiment 2

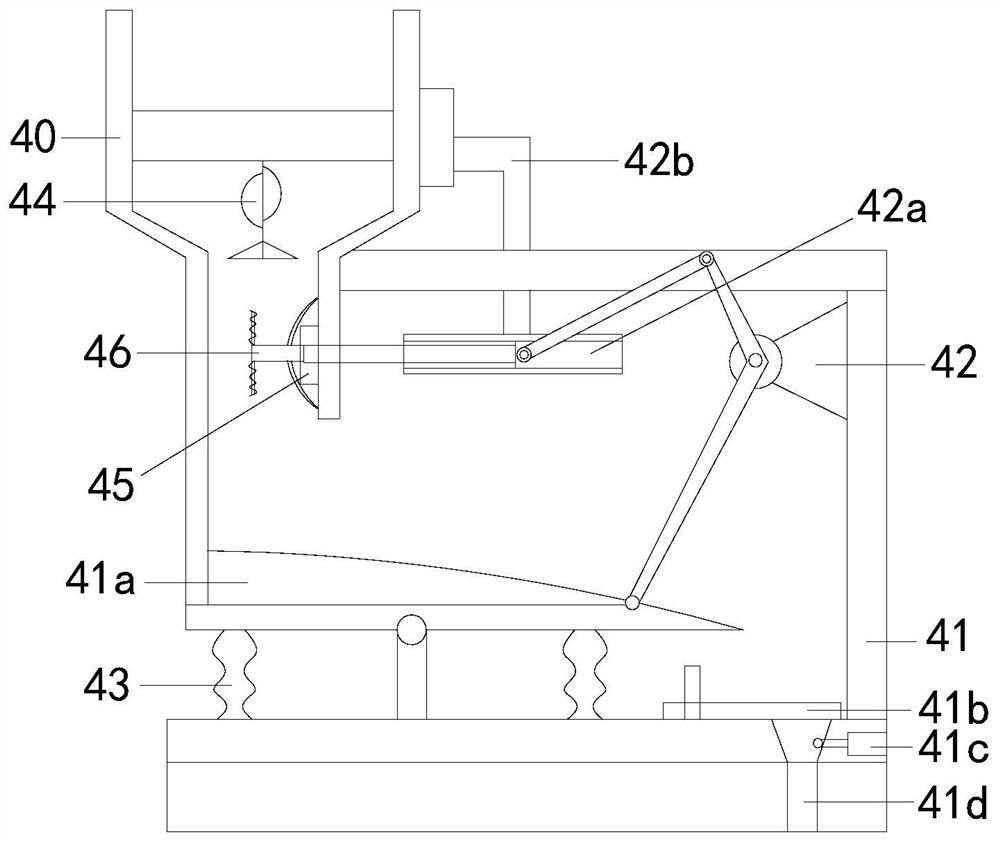

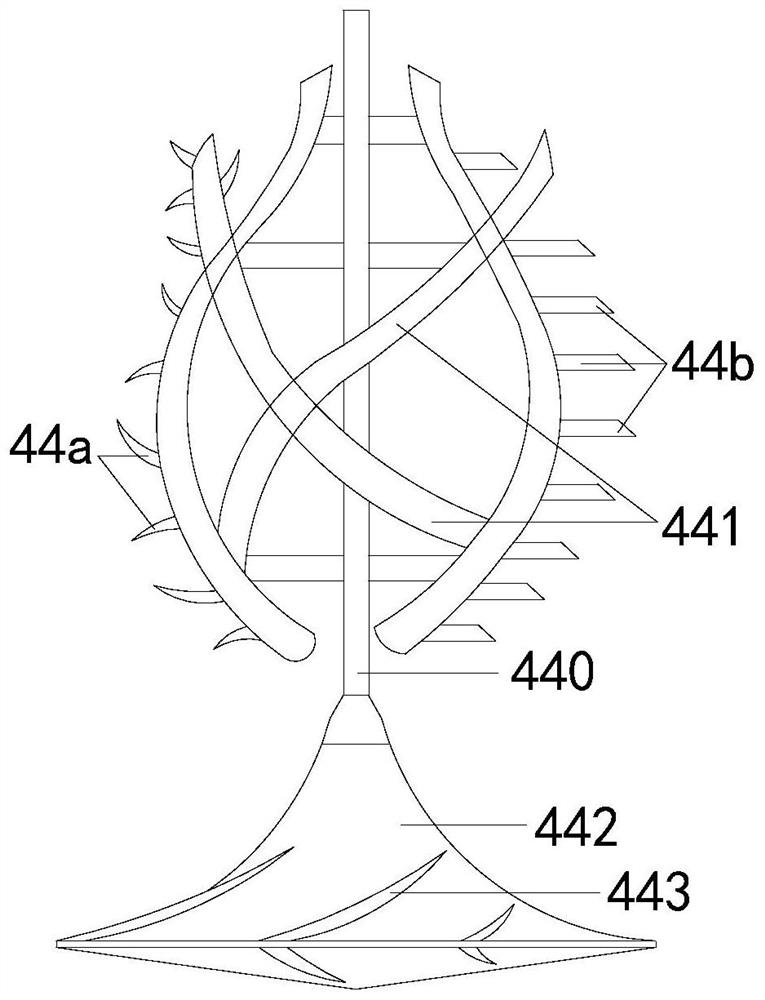

[0030] The description of the second embodiment drawn in conjunction with the first embodiment, combined with figure 2 , image 3 and Figure 5 , the feeding hopper 40 is arranged on the top of the box board 41, the box board 41 is connected with the power arm 42 and is provided with a fixed column 43, the whipping fan shaft 44 is arranged in the feeding hopper 40, and a circulating swivel seat 45 and The crankshaft 46 is thinned and the two are connected to each other. The main shaft 440 is provided with a curved stick frame 441 and its end is connected with a splitter cone 442. The surface of the splitter cone 442 is distributed with diversion grooves 443. Both sides of the vertical shaft 460 are The airfoil 461 is connected and the end is provided with a crushing cone 462. The side of the crushing cone 462 extends outwards to connect with the winding rod 463. In order to avoid the condensate generated by incomplete mixing of chemical materials from blocking the input chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com