Automatic packaging garbage can

A trash can, automatic technology, applied in the field of trash cans, can solve the problems of hand pollution, time-consuming and laborious, unpleasant smell, etc., and achieve the effect of keeping hands clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

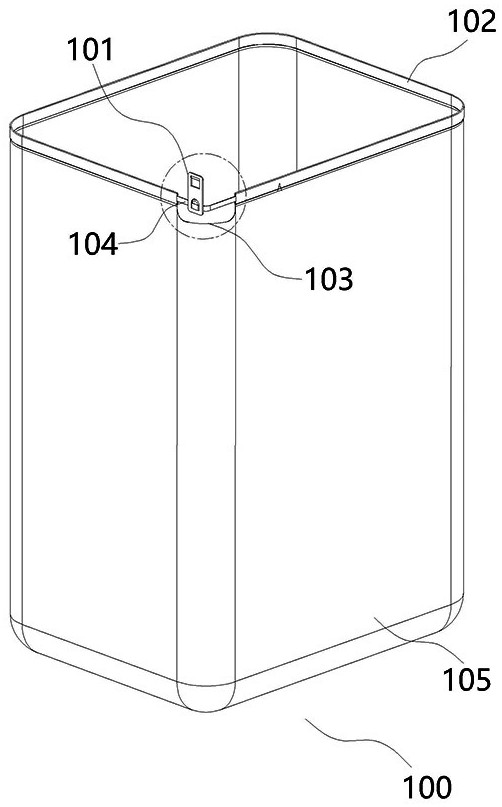

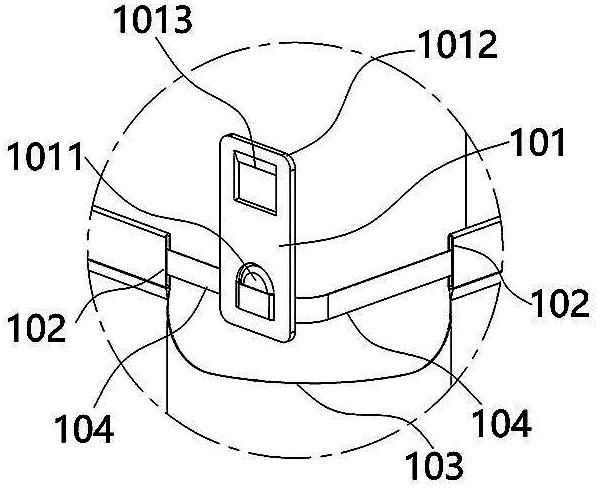

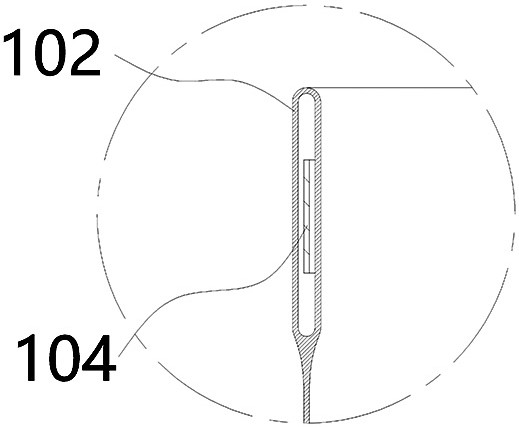

[0074] Such as Figure 23 Shown: a trash can, including a barrel body 401, characterized in that it mainly includes an escapement assembly erected on the barrel body 401; the escapement assembly can at least keep two or more garbage bags in an open state, And can cancel the mouth keeping state of garbage bags one by one. A further solution is to clamp more garbage bags layer by layer on the edge of the bucket body by the escapement assembly. When the garbage bags are full and need to be packed, the escapement assembly can release the bag that carries the garbage. Only a garbage bag can also be used to allow the packing operation of a person or a machine to take away the garbage bag that carries the garbage from the escapement assembly, while the remaining garbage bags continue to be bound by the escapement assembly, so as to keep the garbage. The bag is in an open state. Multiple garbage bags are stored together in the garbage can, which saves the tedious labor of replacing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com