A dual-channel dust-suppressing guide trough for air-material separation

A dual-channel, material-guiding trough technology, applied in the directions of loading/unloading, conveyor objects, transportation and packaging, can solve the problems of reducing induced wind and dust, difficult to control dust, and large belt speed. The effect of suppressing blanking dust, reducing the cost of dust control, and reducing dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

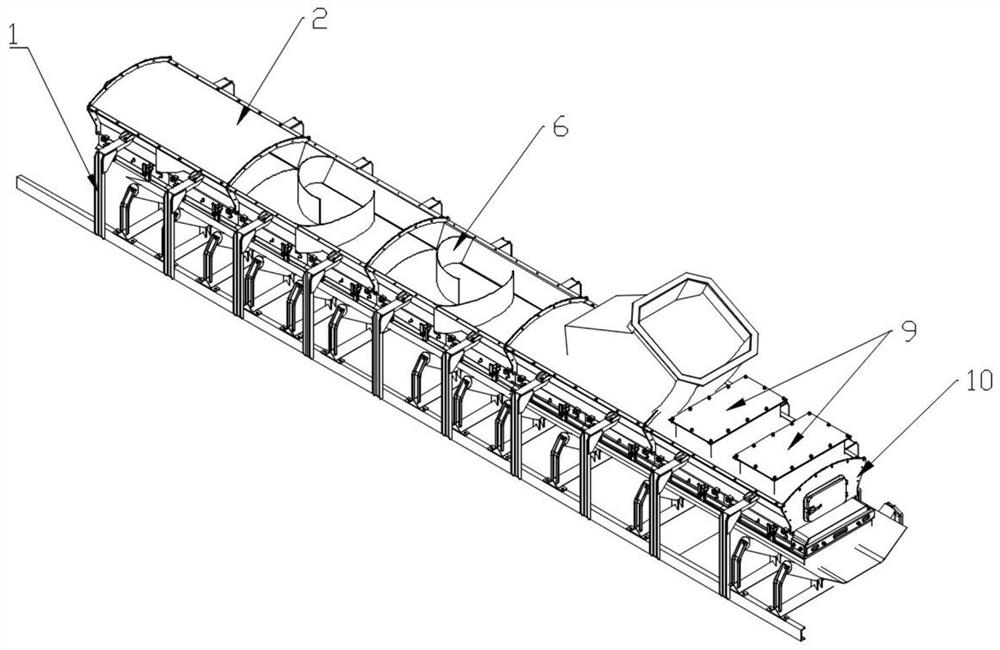

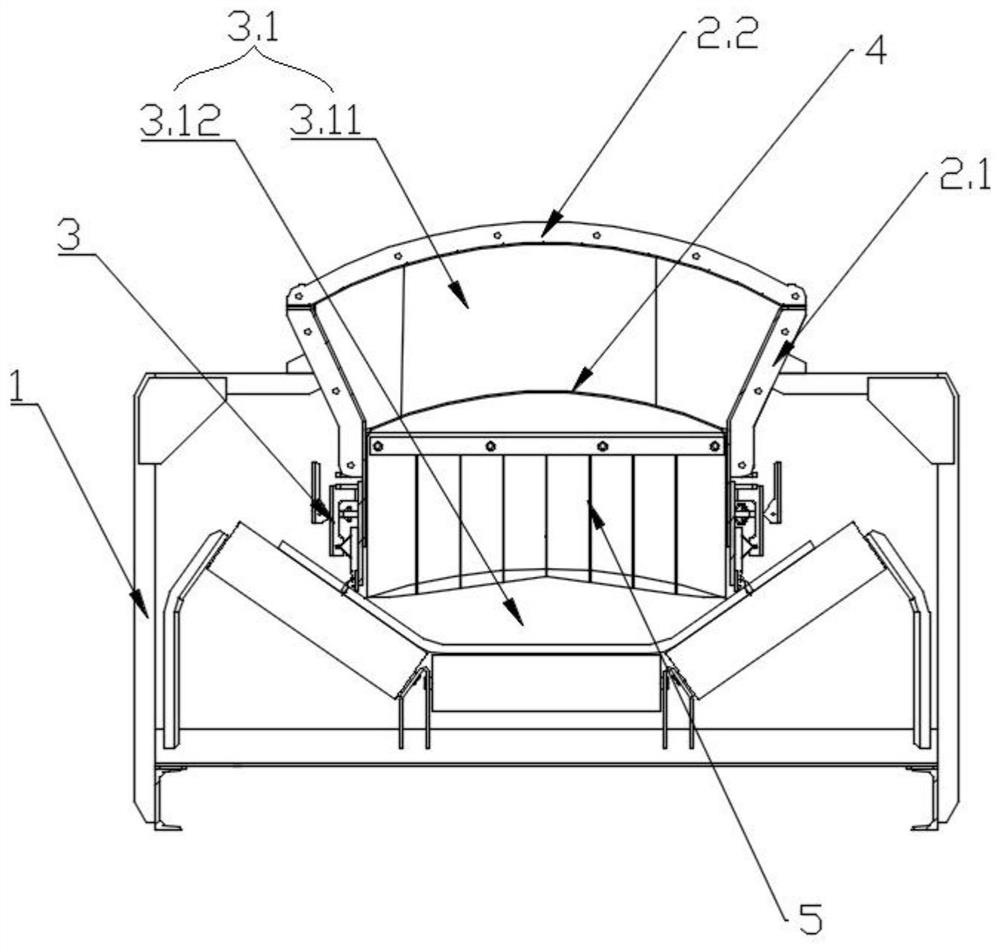

[0036] like Figure 1-3 As shown, the embodiment of the present invention discloses a dual-channel dust-suppressing guide chute for air-material separation, including: multiple pairs of pillars 1, and each pair of pillars 1 is symmetrically installed on the middle frame of the belt conveyor on site, To support the entire chute; the top shield 2, the top shield 2 is installed on the pillar 1, the top shield 2 includes two symmetrically arranged side plates 2.1 and a top cover erected above the side plates 2.2; sealing assembly 3, the sealing assembly 3 is used to connect the top shield 2 and the belt conveyor to form a sealed material guide channel between the top shield 2 and the belt upper surface of the belt conveyor 3.1, the sealing assembly 3 includes a holder, an anti-overflow skirt and a liner arranged on the outside of the side plate 2.1, which are used to block and seal the material in the flow passage, and the anti-overflow skirt is made of polyurethane wear-resistant...

Embodiment 2

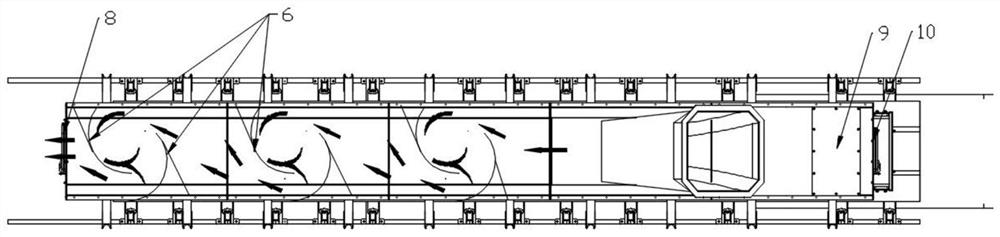

[0044] The difference between this embodiment and Embodiment 1 is that in each attenuation part, two adjacent baffles 6 are arc-shaped baffles, and the arc-shaped openings of the two baffles are arranged in opposite directions, and the The induced wind performs vortex attenuation movement under the action of the arc-shaped baffle, which avoids dust caused by fine materials brought up by the change of wind direction. After the induced wind passes through multiple vortexes, it reaches the filter dust suppression air curtain 8, and the induced wind after the reduced energy is filtered and discharged through the air primary effect metal filter screen on the filter dust suppression air curtain 8.

Embodiment 3

[0046] The difference between this embodiment and Embodiment 1 is that each baffle 6 is only fixedly connected to one of the two side plates, the top cover and the diverter plate, and a plurality of baffles 6 are in the upper channel 3.11. The radial parts are staggered to form a plurality of communicating attenuation channels.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com