Fault Diagnosis Method and Diagnosis System of Engine Temperature Control Module

A temperature control module and fault diagnosis technology, applied in engine cooling, engine components, machine/engine, etc., can solve problems such as increasing complexity, ECU unable to judge intermediate state, thermostat unable to carry out self-diagnosis, etc., to achieve retention functional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific embodiments of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments. The following examples are intended to illustrate the present invention, but not to limit the scope of the present invention.

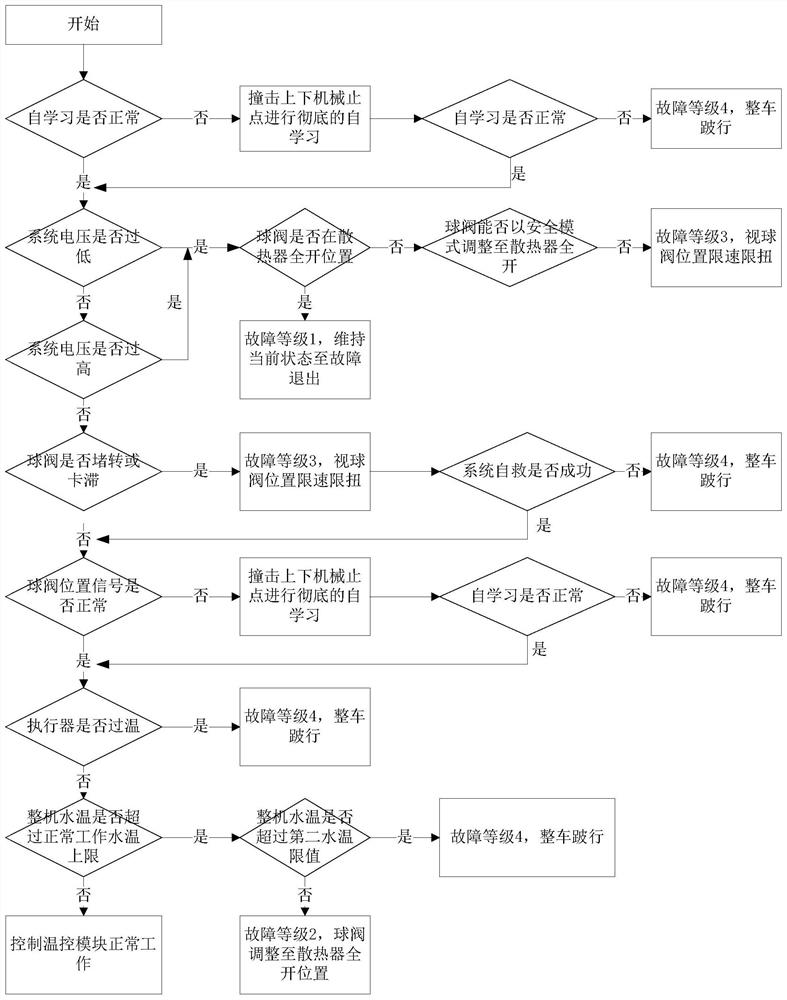

[0038] like figure 1 As shown, the fault diagnosis method of the engine temperature control module provided by the embodiment of the present invention includes:

[0039] Step S10: After the engine is started, self-learning of the temperature control module is performed.

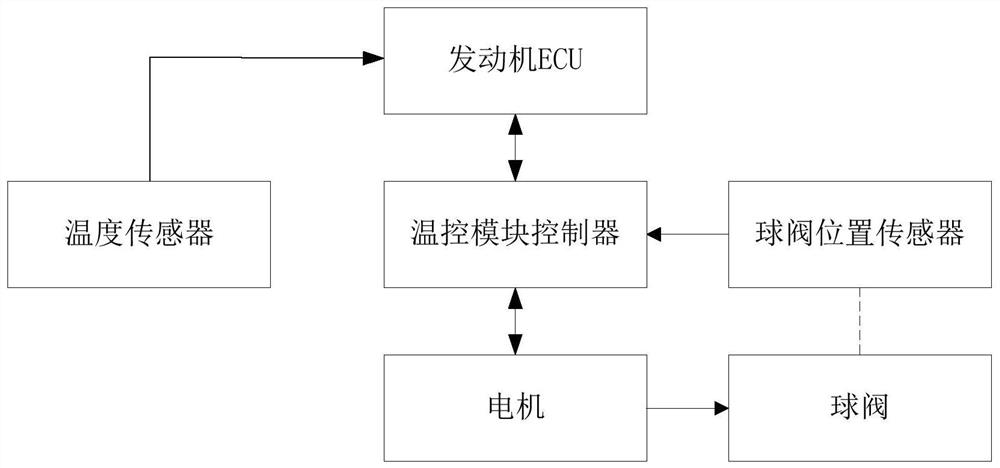

[0040] In step S10, after the engine is started, the engine ECU sends a signal to the temperature control module controller, and the temperature control module controller starts the temperature control module self-learning after receiving the signal. When the temperature control module is self-learning, it is to check whether the stroke of the ball valve meets the design value without hitting the upper and lower dead centers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com