Test tube detection device and test tube detection method

A test tube detection and test tube technology, which is applied in the direction of measuring devices, test tube holders/clamps, and the counting of items shipped by conveying devices, etc. The detection process is convenient and the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

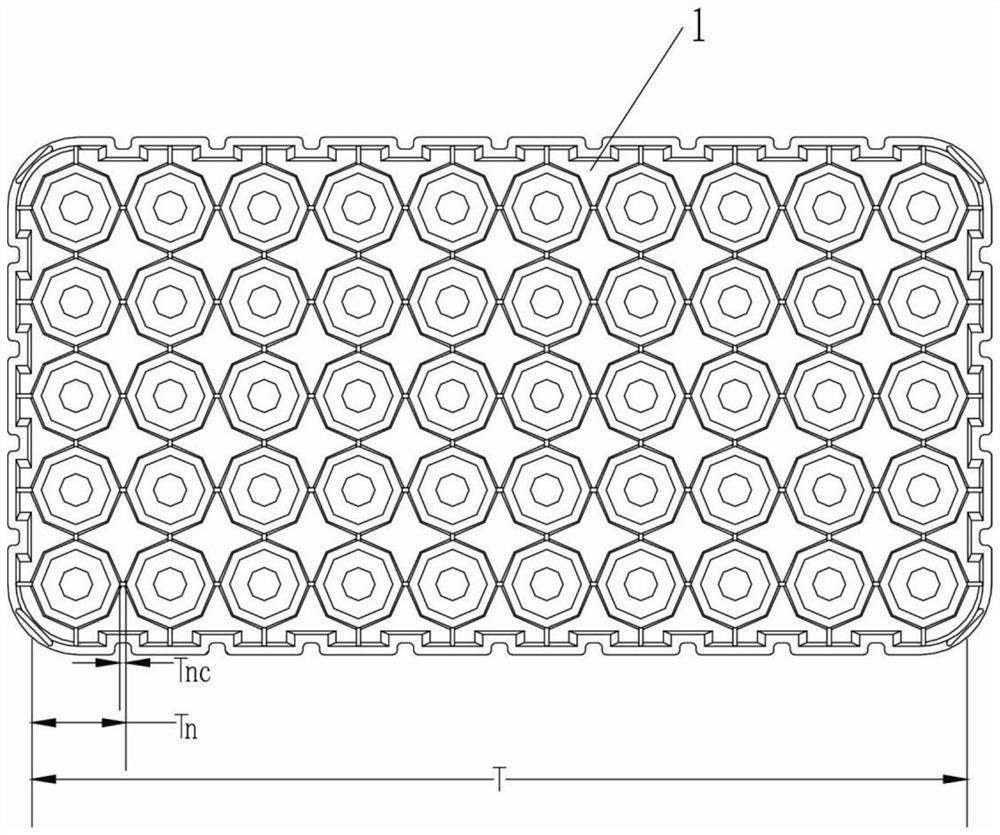

[0073]Example 1: The first two test tube grooves in the single column tube are not loaded, and the remaining tube grooves are loaded with the test tube, and according to the above method, the test tube detection module detects the test tube within TN × 3 time, which will be detected from the third test tube. Start re-timing, continue moving, when arriving at the start position of the fourth test tube, passing time is Tn, then in TN × 3 ~ (TN × 4-TNC) time, TN × 3 ~ (TN × 4-TNC) is equivalent to the passage of the fourth test tube cap because the fourth test tube is loaded with the fourth test tube, so the accumulation is TN + (TN-TNC) = (Tn × 2-TNC) Until the last 10th test tube, the accumulation is final (Tn × 8-TNC), and finally the time is the third test tube to the 10th test tube.

Embodiment 2

[0074]Example 2: Two tube grooves of the single row tube groove unloading tube (i.e., the fifth and sixth test tube grooves are not loaded), and the remaining tube grooves are loaded with the test tube, followed by the above method, the test tube detection module in TN × The test tube was detected in 1 time, starting timing, the time accumulated at the start of the fifth test tube is Tn × 4, and then passing the fifth tube groove during Tn × 4 ~ (Tn × 5-TNC) At this time, at this time, the test tube detection module did not detect the test tube, and did not make time accumulation. The six test tube groove was not loaded. When it was not accumulated, until the seventh test pipe groove was reached, the test tube was detected, and the test tube was detected, and when the finals were started The 10th test tube is (TN × 8-TNC) at the time of accumulation.

Embodiment 3

[0075]Example 3: The last two test tube grooves of the single row tube groove are not loaded with the test tube (ie, the ninth and 10th test tube grooves are not loaded. The remaining test tube grooves are loaded with the test tube, followed by the above method, and the accumulation is finally To (TN × 8-TNC).

[0076]Step 207: Analyze the number of test tubes loaded by the test tube rack at the current column of the test tube groove according to the accumulation timing.

[0077]Step 208, the number of test tubes loaded by each test tube detection module is accumulated to obtain the total number of test tubes loaded by the current test tube frame.

[0078]Such asFigure 6 As shown in an embodiment, the data processing analysis module analyzes the working method of the number of test tubes, as well as:

[0079]In step 209, the test tube is divided into three aliquots by the time of the test tube detection module, and the detection of three detection, two or more, confirmed that the current test t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com