Eddy current conductivity measurement sensor

A technology for measuring sensors and conductivity, applied in measuring devices, measuring electrical variables, measuring resistance/reactance/impedance, etc., can solve the problems of low resolution of measuring sensors and great influence of lift-off, etc., to ensure measurement accuracy and device The effect of simple structure and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

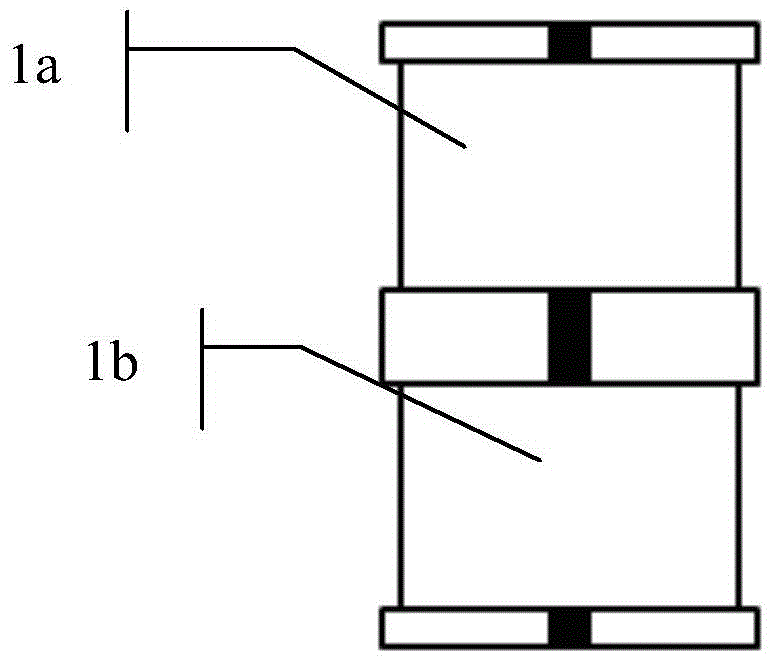

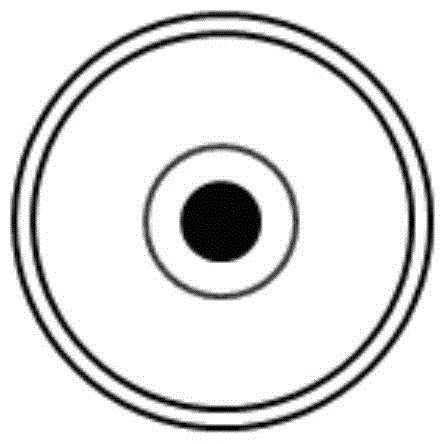

[0037] The structural block diagram of sensor of the present invention is as Figure 1-Figure 5 As shown, the sensors include:

[0038] The measuring probe 1 and the signal processing circuit are connected by a connecting cable;

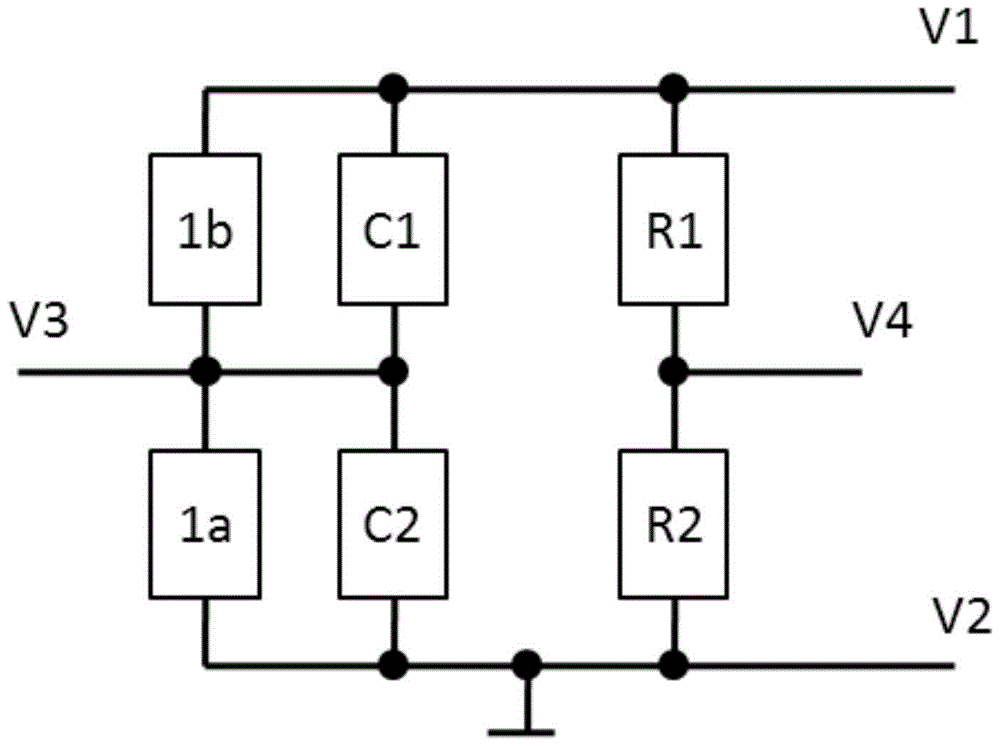

[0039] The measuring probe includes: a measuring coil 1a, a compensation coil 1b, the parameters of the measuring coil and the compensation coil are exactly the same, the measuring coil and the compensation coil are connected in a differential manner, and an AC bridge structure is used for output; a handheld heat-insulating shell, an electromagnetic shielding layer, micro switch, pressure spring, detection circuit, temperature sensor and connecting cable;

[0040] The measuring coil is placed at one end of the hand-held heat-insulating housing and the measuring surface is exposed; the pressure spring is located between the first protrusion 11 and the second protrusion 12;

[0041] The signal processing circuit includes: a sine excitation unit, a ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com