Blade type rapid mechanical optical switch based on piezoelectric driving

A piezoelectric drive, blade technology, applied in optics, optical components, instruments, etc., can solve the problems of slow response, small clear aperture, slow switching speed, etc., to save manpower and material costs, reduce displacement stroke requirements , the effect of improving the efficiency of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

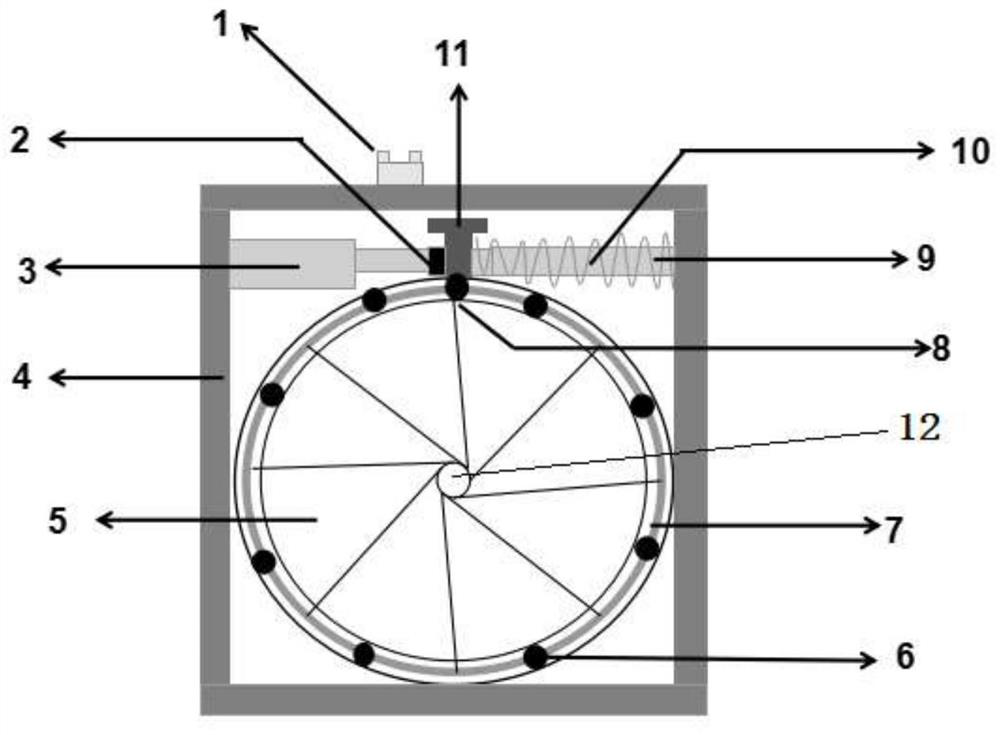

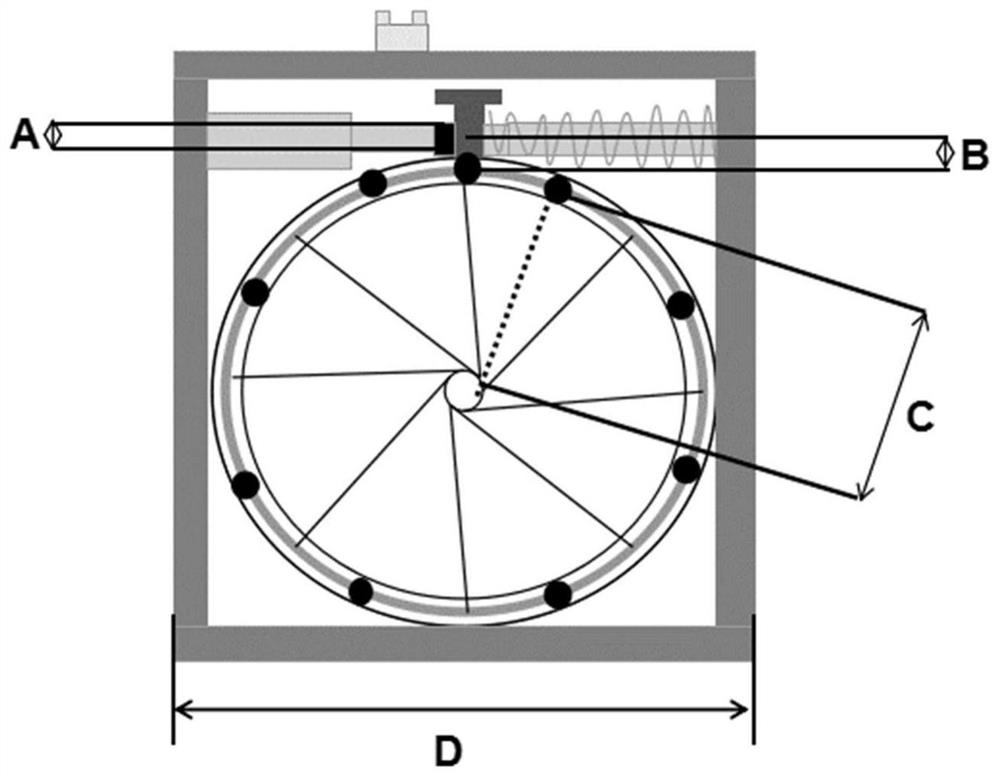

[0021] A blade-type fast mechanical optical switch based on piezoelectric drive, including an aperture diaphragm and a piezoelectric ceramic stack 2, the aperture diaphragm includes eight metal blades 5, and the metal blades 5 are fixed in a fixed snap ring 7, both Fixed by the fixing screw 6 , one end of the blade control rod 11 is fixed on the fixing snap ring 7 by the main fixing screw 8 , and the other end is in contact with the piezoelectric ceramic stack 2 . When the aperture diaphragm is opened, all the metal blades 5 can spread out around the light hole and around the fixed snap ring 7 . The aperture diaphragm is installed inside the metal housing 4, and the two sides of the blade control rod 11 of the aperture diaphragm are respectively provided with a piezoelectric ceramic stack 2 and a return spring 10, and the piezoelectric ceramic stack 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com