Gluing device for leather shoe manufacturing

A technology for leather shoes and gluing, applied in footwear, application, bonding shoe parts, etc., can solve the problems of low production efficiency, waste of materials, excess waste glue, etc., and achieve the effect of reducing waste, reducing waste glue, and high operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

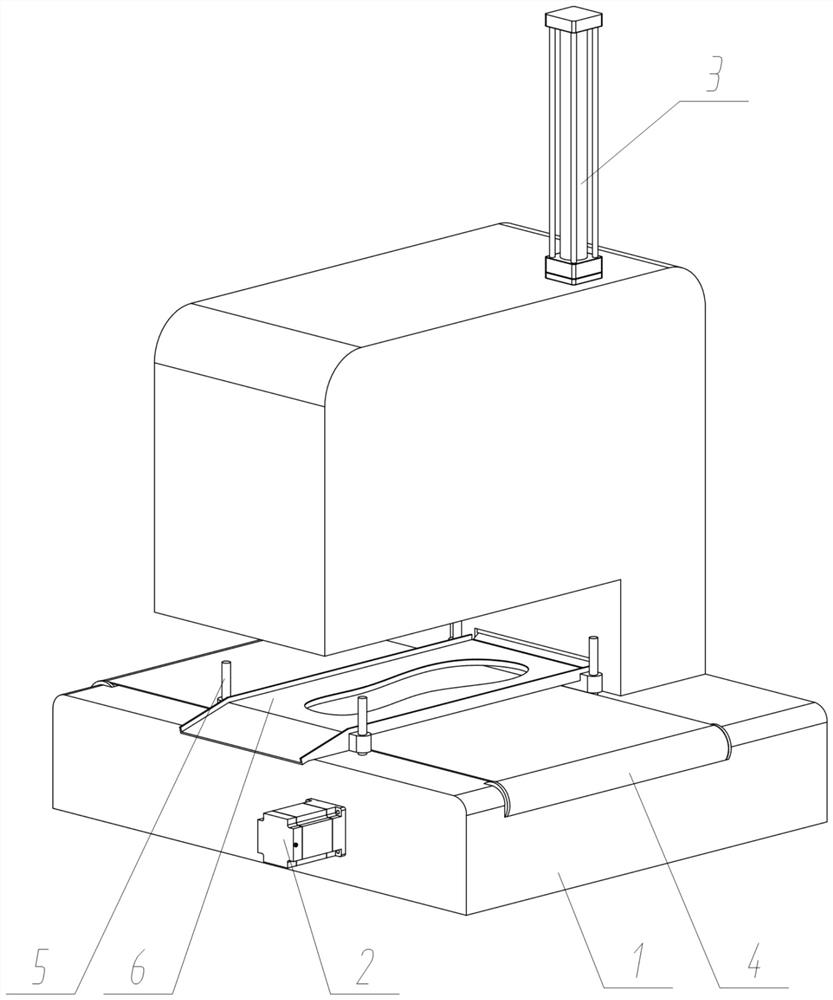

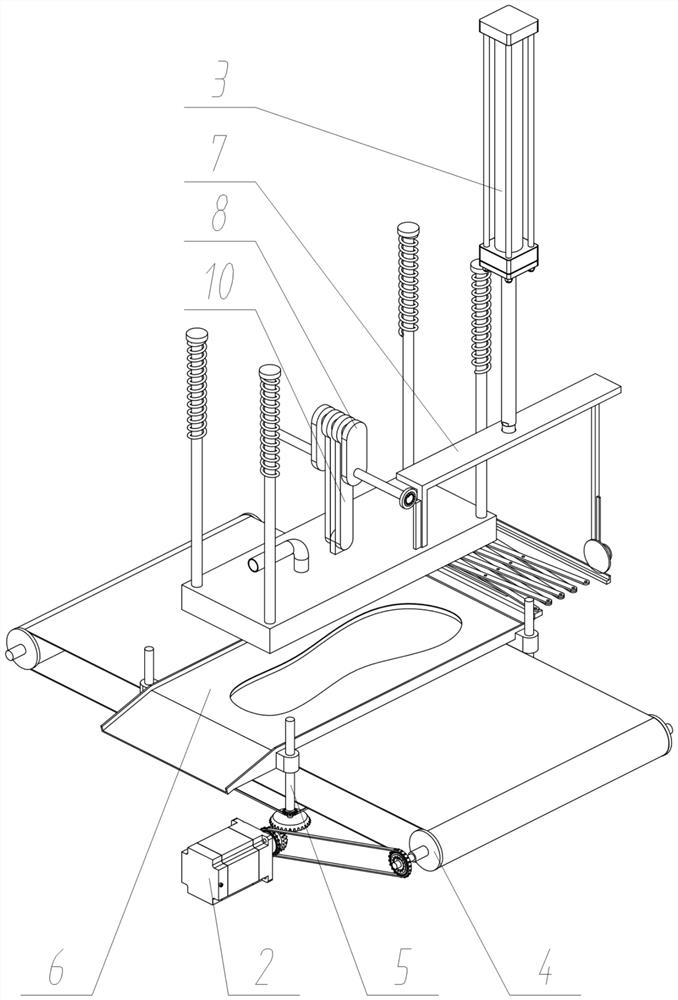

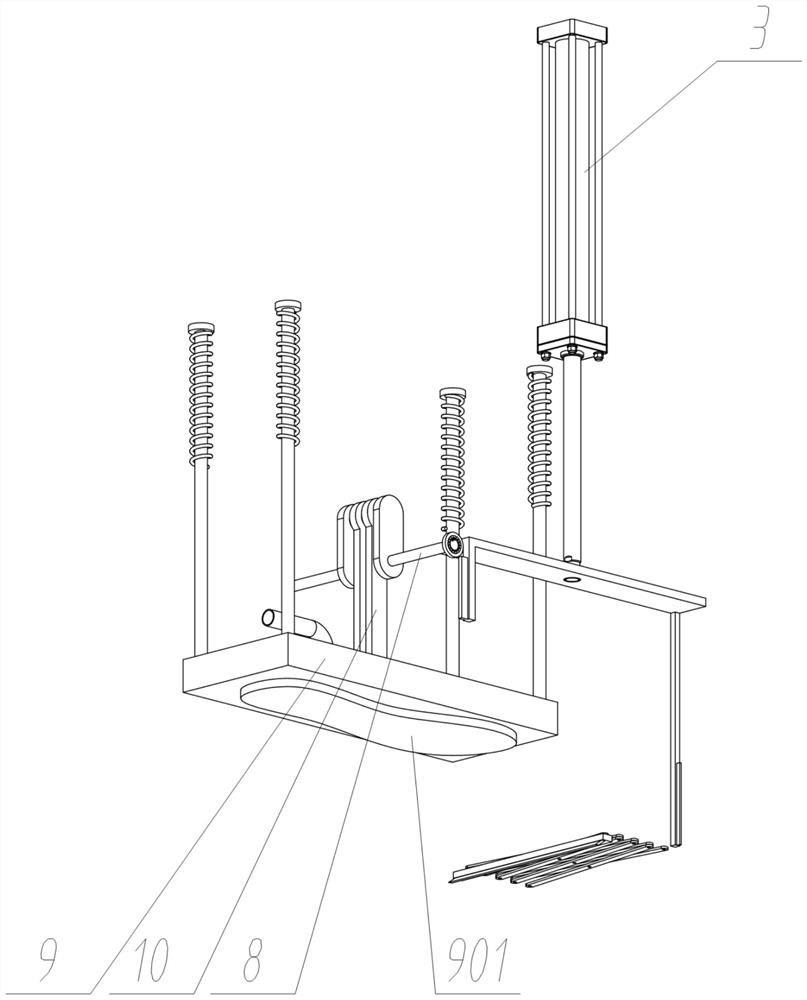

[0032] see Figure 1 to Figure 10 , an embodiment provided by the present invention: a gluing device for manufacturing leather shoes, comprising an outer shell 1; a group of transmission drive parts 2 is fixedly connected to the front end of the outer shell 1; The driving part 3; the outer casing 1 is provided with a group of transmission devices 4; the lower part of the outer casing 1 is rotatably connected with four sets of lifting drive screw 5; There is a group of gluing driving blocks 7 slidingly connected to the upper part of the inner side; the gluing driving block 7 is fixedly connected with the piston rod of the gluing driving part 3; There is a group of gl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap