Intelligent maintenance structure and maintenance method for cantilever end concrete of cantilever pouring bridge

A technology of concrete and cantilever ends, which is applied in the direction of bridges, bridge materials, bridge construction, etc., and can solve problems such as occupation of human resources, water loss, and difficulty in ensuring the quality of concrete maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

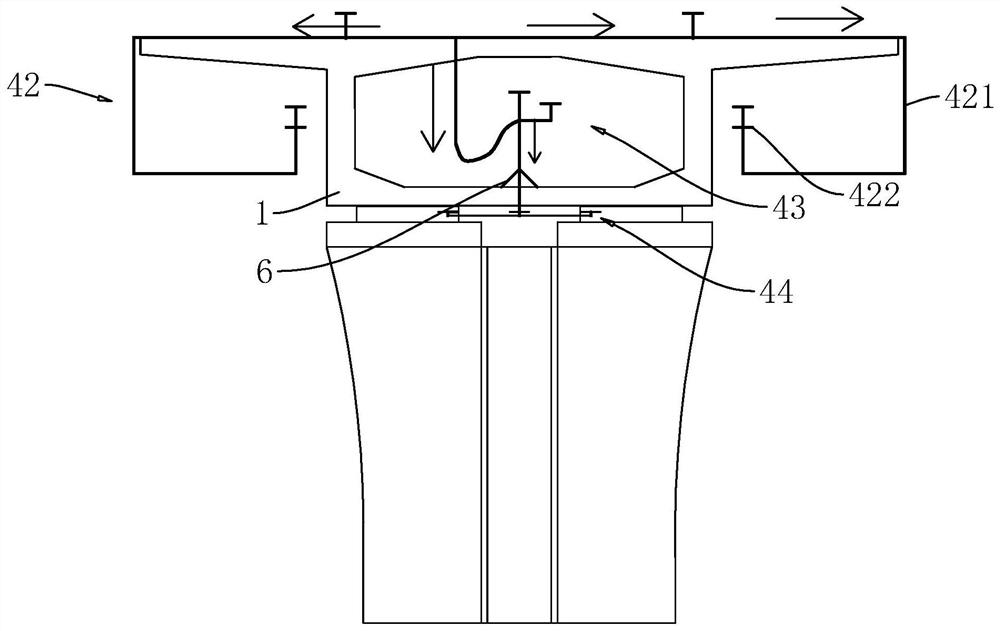

[0044] The following is attached Figure 1-4 The application is described in further detail.

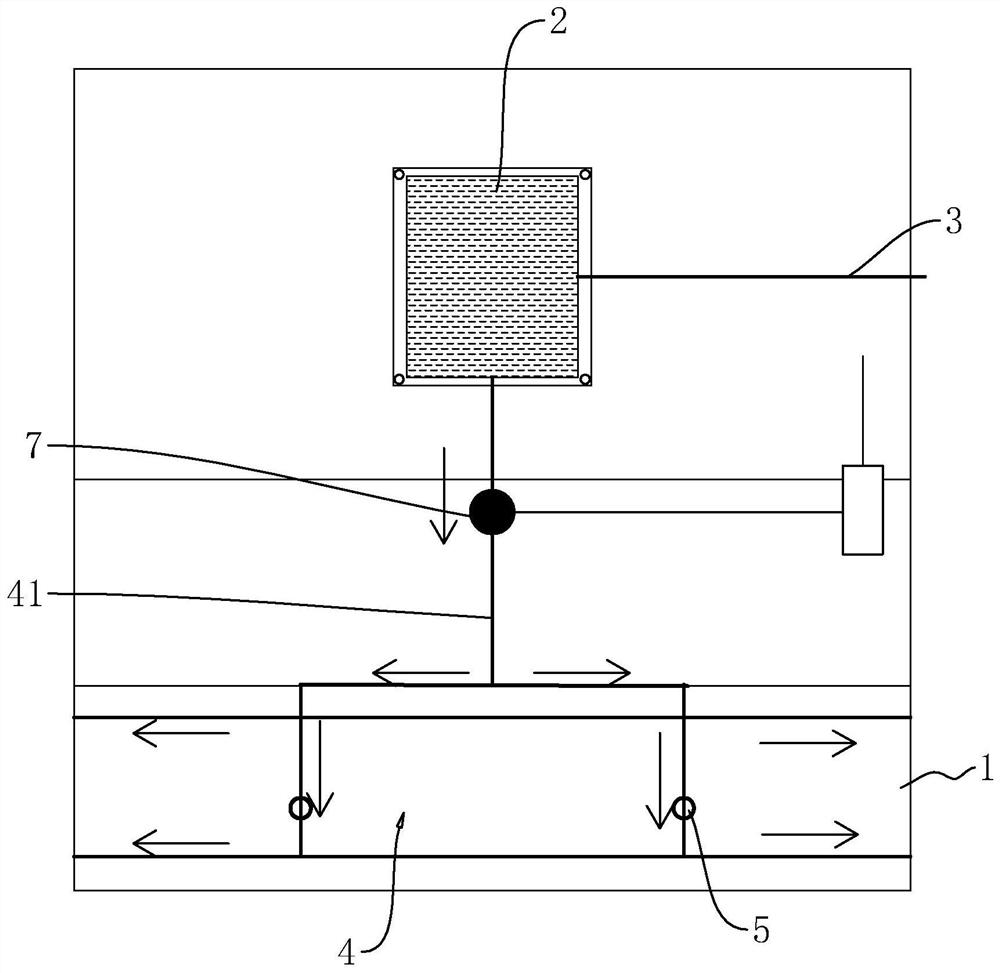

[0045] The embodiment of the present application discloses an intelligent maintenance structure and maintenance method for cantilever end concrete of a cantilever pouring bridge. refer to figure 1 , the intelligent maintenance structure for concrete at the cantilever end of a cantilever poured bridge includes a water storage tank 2, a water supply pipeline, a sprinkler system 4 and an intelligent control system 7;

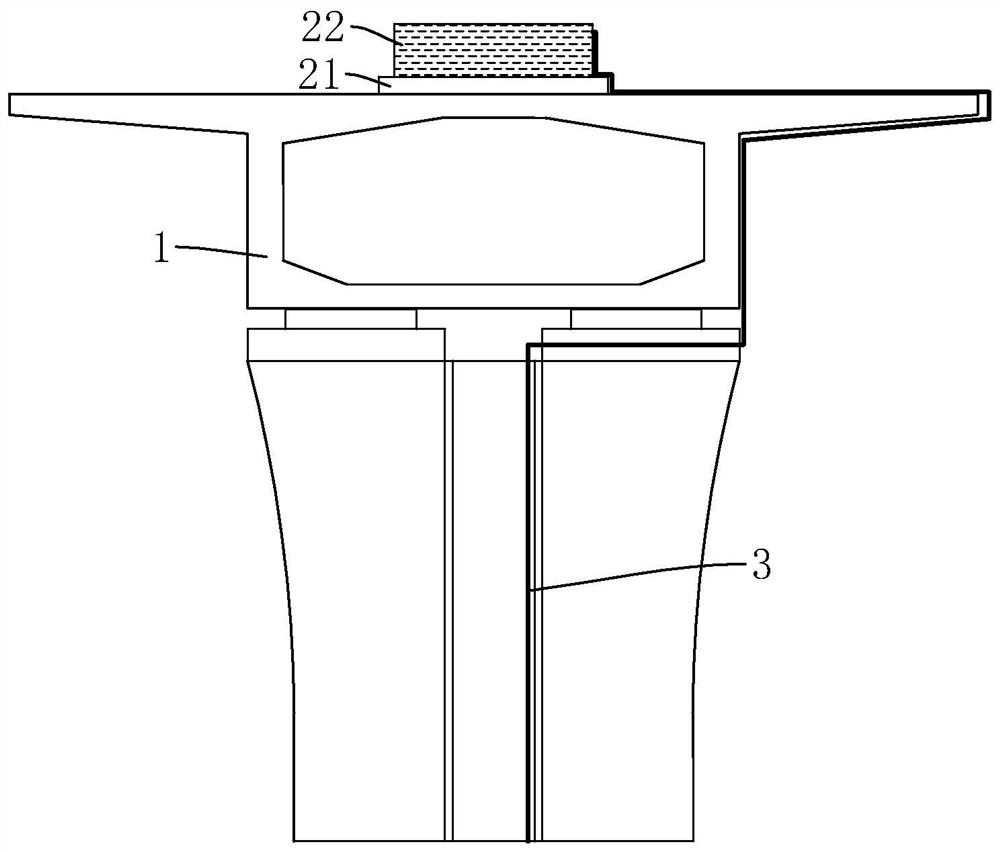

[0046] refer to figure 2 The water storage tank 2 is installed on the top plate of the beam body 1 to supply water for concrete maintenance. The water storage tank 2 includes a base 21 and a box body 22. The base 21 is a rectangular steel plate whose plane size is slightly larger than the box body 22. The four corners are respectively Holes are opened, and the beam body 1 is fixedly connected by bolts. The box body 22 is fixed on the base 21, and the box body 22 is lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com