Surface mine frozen soil layer blasting method

A technology for permafrost and mines, which is applied in the field of permafrost blasting in open-pit mines, and can solve the problems affecting permafrost blasting efficiency and waste of explosives.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

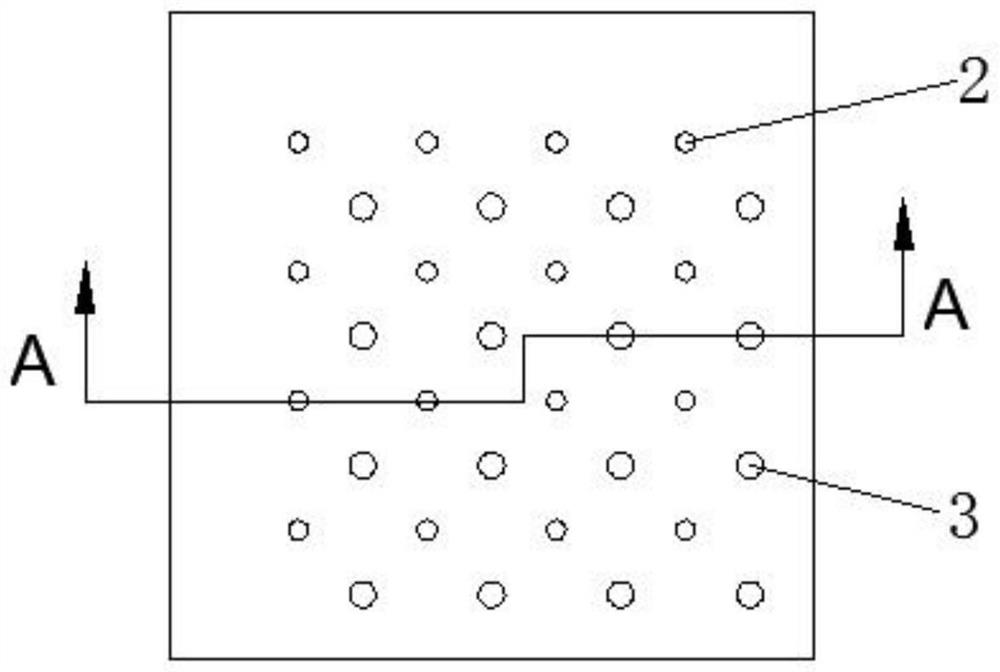

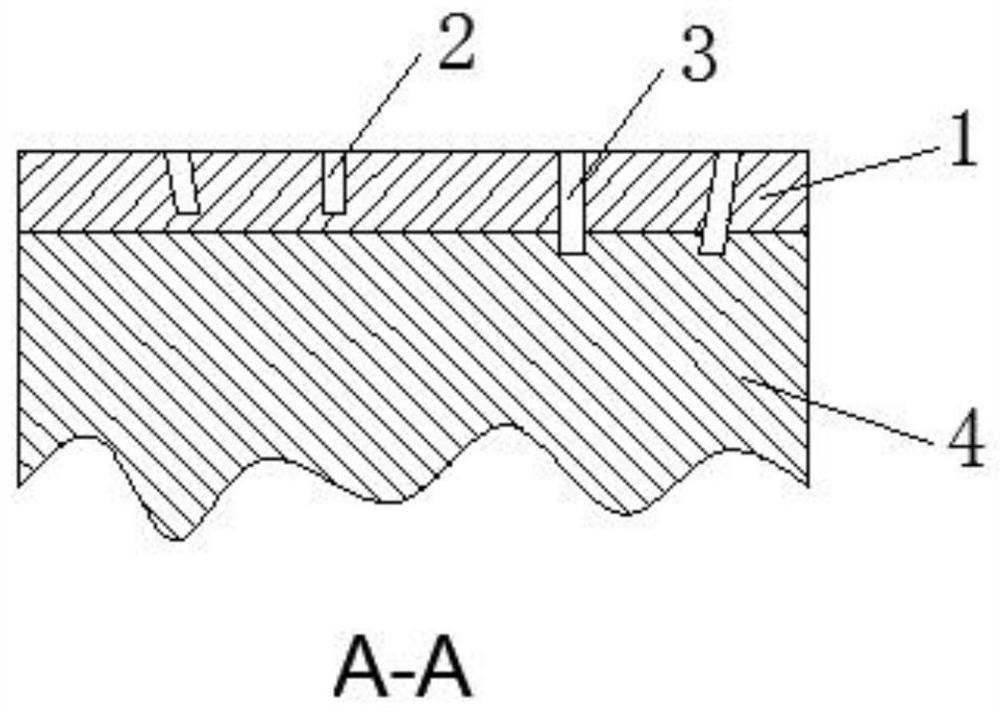

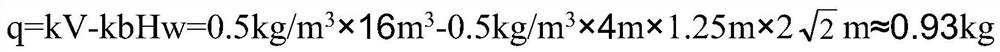

[0046] The permafrost layer 1 blasting was carried out in Xinjiang South Open-pit Coal Mine in November 2019. The thickness h of the permafrost layer 1 was 1m. The blasting area S was determined to be 20m×20m. The explosive used was ammonium oil explosive. L is 4m, therefore, the depth h of the blast hole 2 1 =0.8h=0.8m, the spacing a of the blasting holes 2 is 4m, the depth H of the auxiliary blasting holes 3 is 1.25m, between H=1.0h-1.4h, the diameter of the drill bit is 65mm, according to the blasting of various rocks Look up the k-value table of unit explosive unit consumption, and the unit consumption k of explosive in solid permafrost layer 1 is 0.4-0.5kg / m 3 , choose the maximum value in this embodiment, k=0.5kg / m 3 , the row spacing of the row of holes is a, a=4m, the hole spacing of the same row of adjacent blast holes 2 is b, b=4m, therefore, the distance w between the auxiliary blast hole 3 and the blast hole 2 is The blasted frozen soil volume of each blast hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com