A blasting method for permafrost in open-pit mines

A technology for permafrost and mines, applied in the field of permafrost blasting in open-pit mines, can solve problems affecting blasting efficiency in permafrost, waste of explosives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

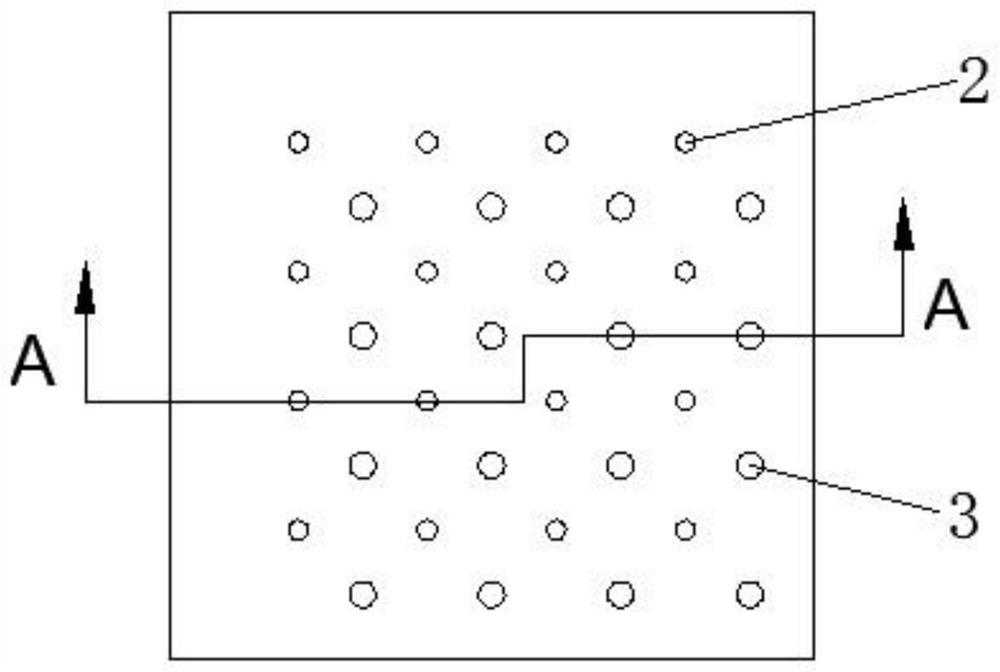

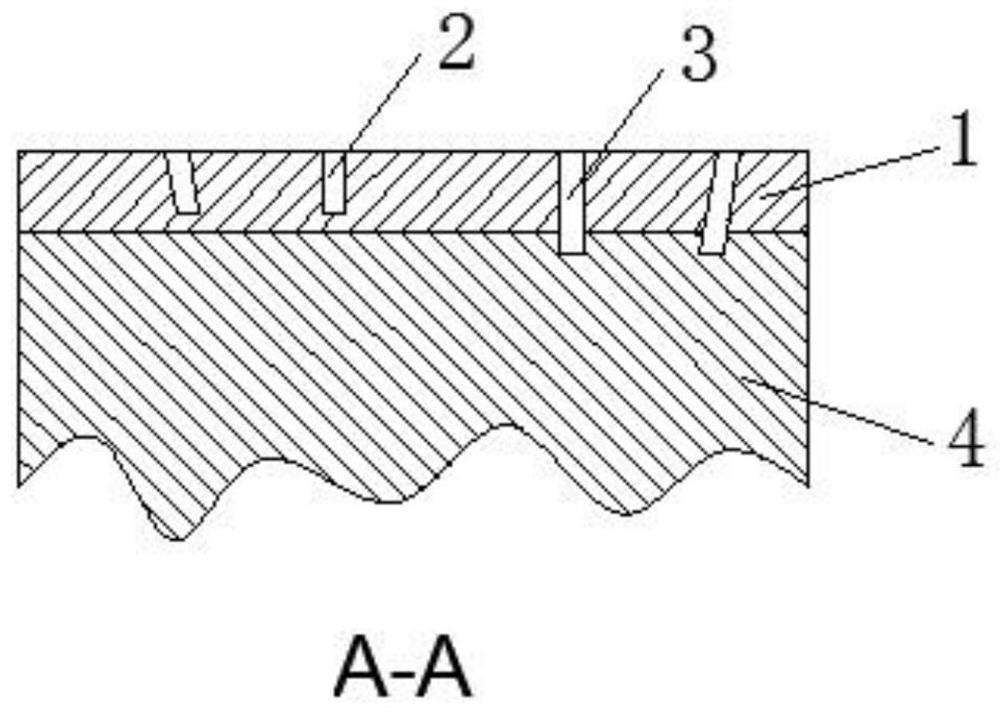

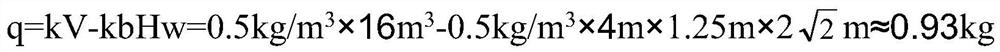

[0046] The permafrost layer 1 blasting was carried out in the southern open-pit coal mine in Xinjiang. The time was November 2019. The thickness h of the permafrost layer 1 was 1m. The blasting area S was determined to be 20m×20m. The explosive used was ammonium oil explosive. L is 4m, therefore, the depth h of the blast hole 2 1 =0.8h=0.8m, the spacing a of the blast holes 2 is 4m, the depth H of the auxiliary blast holes 3 is 1.25m, between H=1.0h-1.4h, the diameter of the drill bit is 65mm, according to the blasting of various rocks Look up the k-value table of unit explosive unit consumption, and the unit consumption k of explosive in solid permafrost layer 1 is 0.4-0.5kg / m 3 , choose the maximum value in this embodiment, k=0.5kg / m 3 , the row spacing of the row of holes is a, a=4m, the hole spacing of the same row of adjacent blast holes 2 is b, b=4m, therefore, the distance w between the auxiliary blast hole 3 and the blast hole 2 is The blasted frozen soil volume of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com