Water pressure detonating method for angle steel structure power transmission tower

A technology for hydraulic blasting and power transmission towers, applied in the blasting field, can solve the problems of high labor intensity, poor blasting effect, low work efficiency, etc., and achieve the effects of improving the degree of blasting damage, simple installation and ensuring blasting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

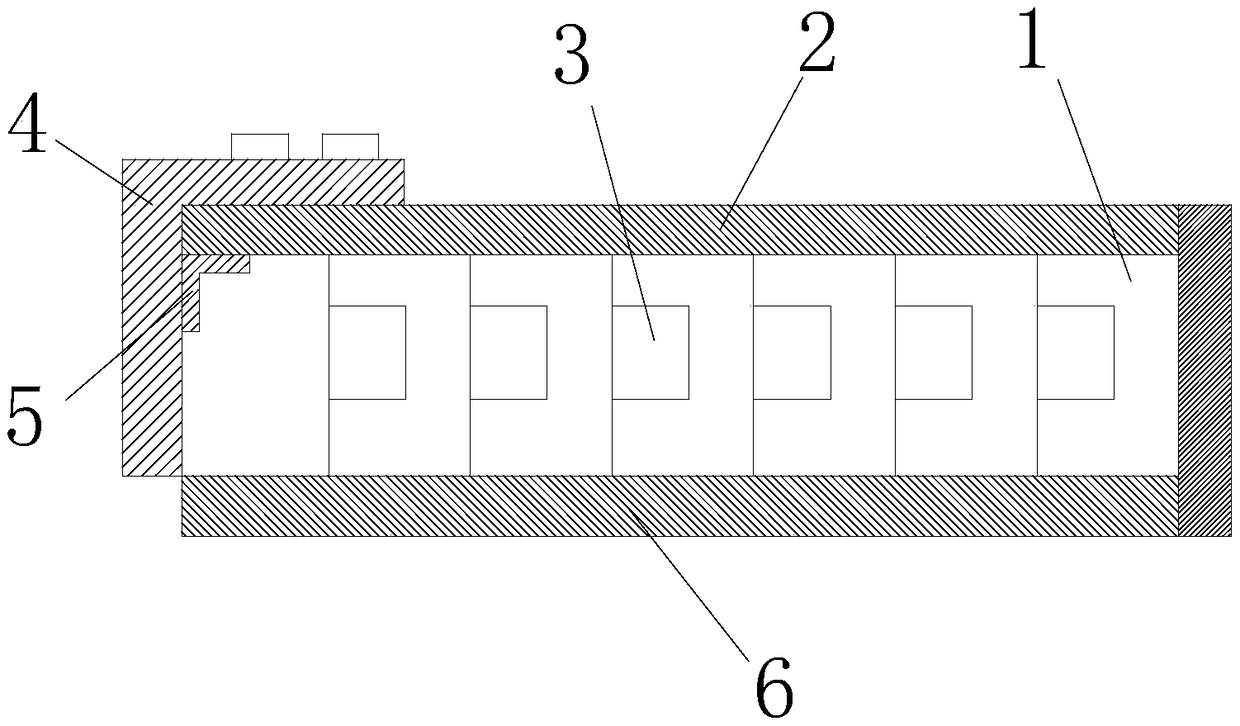

[0017] Such as figure 1 Shown, the hydraulic blasting method of angle steel structure transmission tower of the present invention comprises the following steps:

[0018] (1) punch threaded holes on the first angle steel 2, weld the inside of one end of the first angle steel 2 or install the third angle steel 5 by bolts;

[0019] (2) The first angle steel 2 is welded on the angle steel 6 to be blasted, welded into a cylindrical structure, a steel plate is welded at the bottom of the cylindrical structure, and the bottom of the cylindrical structure is sealed;

[0020] (3) Put the water bag 1 and the drug pack 3 alternately into the cylindrical structure, and the drug pack 3 is drawn out of the cylindrical structure through the nonel detonator;

[0021] (4) fixing the second angle steel 4 with the first angle steel 2 and the third angle steel 5 by bolts, and sealing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com