Low-frequency large-displacement bumping test table with protection function

A protection function and large displacement technology, which is applied in vibration testing, machine/structural component testing, vibration suppression adjustment, etc., can solve the problems of inconvenient adjustment of the length of the drive rod, inconvenient protection of power motors, inconvenient observation of obstructions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

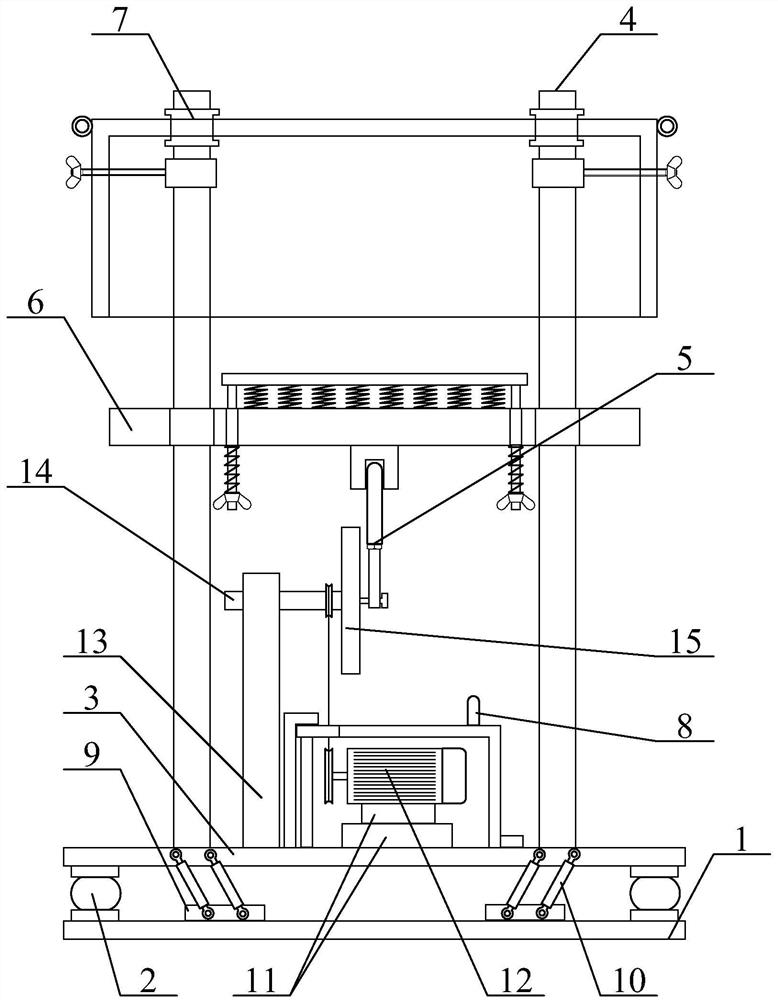

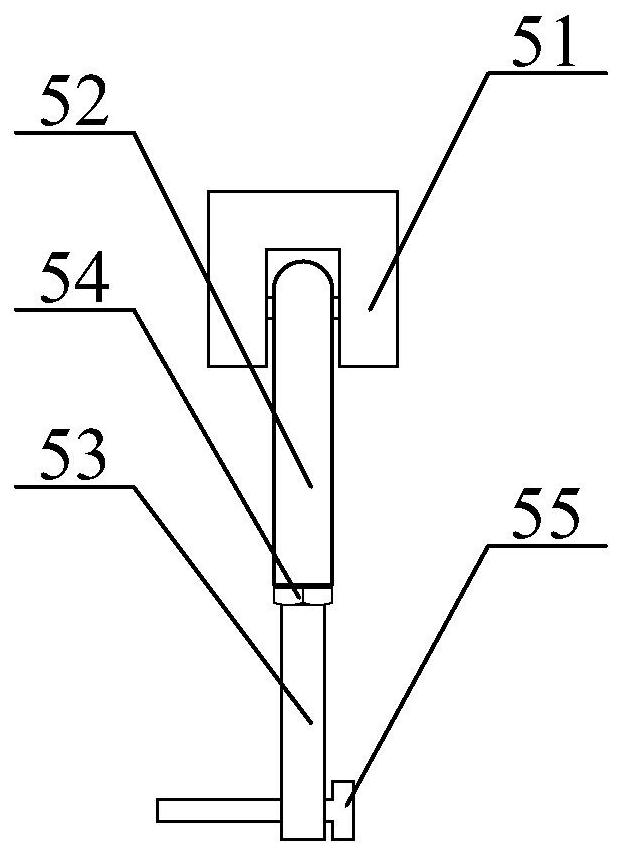

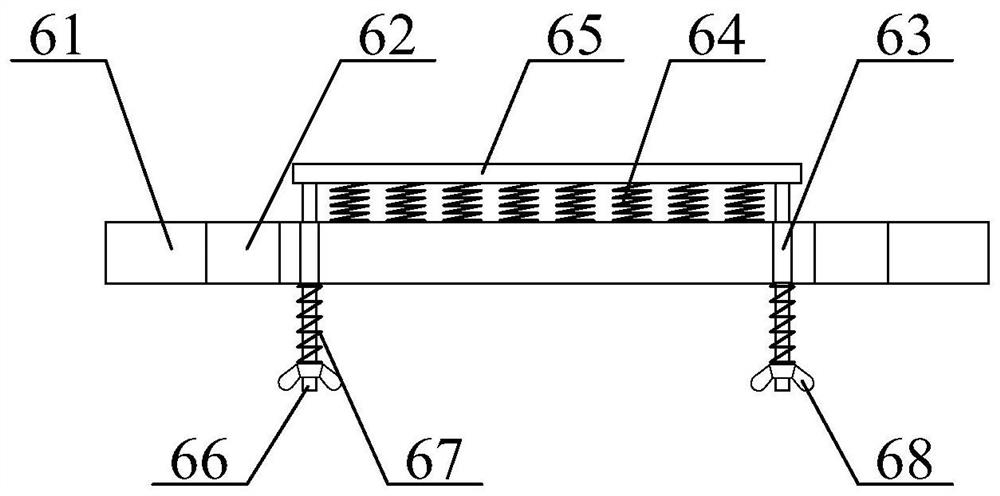

[0035] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2 As shown, a low-frequency large-displacement bumping vibration test bench with protection function includes a bottom plate 1, a shock-absorbing airbag 2, a first fixed plate 3, a guide column 4, an adjustable telescopic locking drive rod structure 5, and can be adjusted by lifting and buffering Experimental platform structure 6, slidable sleeve locking cover structure 7, pluggable adsorption protective cover structure 8, connecting seat 9, shock absorber 10, motor seat 11, driving motor 12, fixed frame 13, rotating support rod 14 and Height adjustment rotating disc 15, the lower ends of the shock-absorbing airbags 2 are respectively bolted to the upper corners of the bottom plate 1; the upper ends of the shock-absorbing airbags 2 are respectively bolted to the lower corners of the first fixed plate 3; The lower ends of the guide colum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com