Finite element modeling method for simulating bolt collision fracture failure

A modeling method and finite element technology, applied in the fields of instruments, electrical digital data processing, geometric CAD, etc., can solve the problems of inability to simulate bolts accurately and the contact relationship of bolt structures, so as to shorten the development cycle and improve the reliability. , the effect of reducing development costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

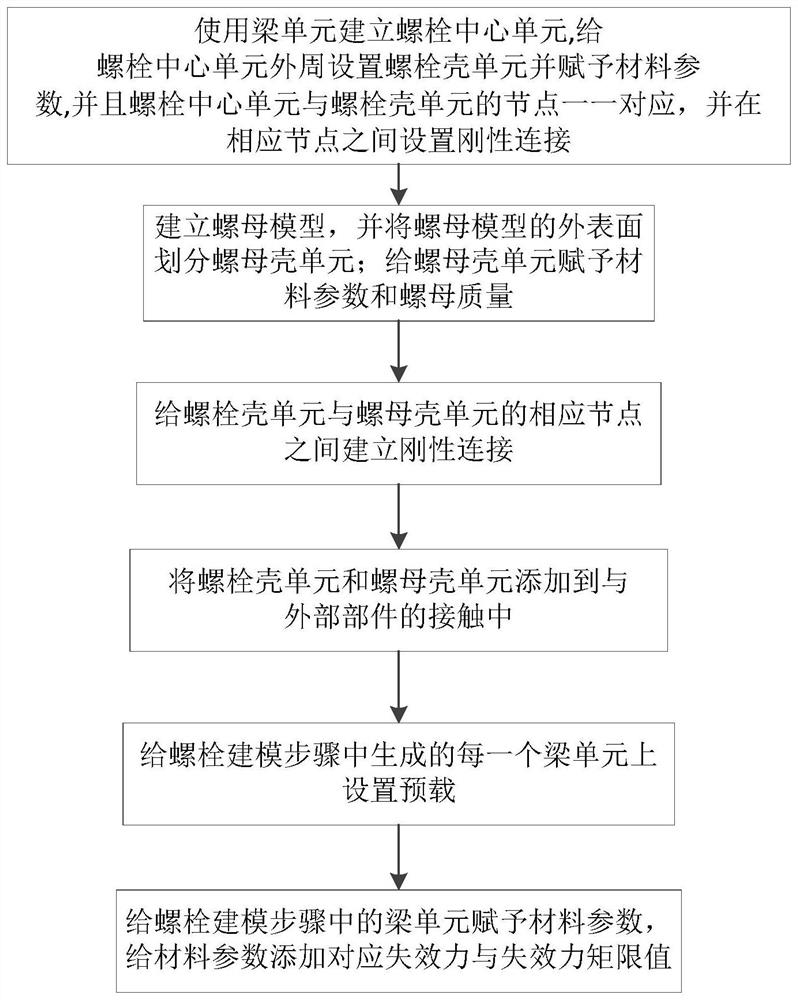

[0054] Provide a finite element modeling method for simulating the failure of bolt collision fracture, the analysis software is LS-dyan, such as figure 1 shown, including the following steps:

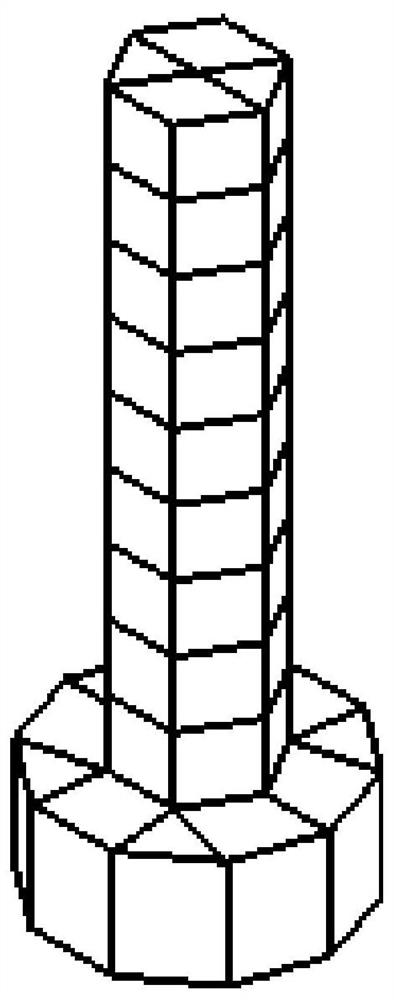

[0055] Bolt model modeling steps: layout points and use such as figure 2 The shown beam unit (the beam unit is displayed as BEAM in the analysis software LS-dyan) establishes the bolt central unit, and sets the outer circumference of the bolt central unit as follows: image 3 shown in the bolt shell unit, and assign material parameters to the bolt shell unit; among them, the bolt central unit corresponds to the nodes of the bolt shell unit one by one, and a rigid connection is set between the bolt shell unit and the corresponding nodes of the bolt central unit, and the following is obtained: Figure 4 The bolt model shown.

[0056] Specifically, in the bolt model modeling step, the bolt model is the most important part of the entire bolt connection modeling, and the contact and load ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com