Ceiling intelligent sound equipment host convenient to disassemble

A smart audio, easy-to-remove technology, applied in the transducer shell/cabinet/stand, signal transmission system, instrument, etc., can solve the problem of the mounting hole becoming larger, and achieve the effect of avoiding displacement, easy cleaning, and easy to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

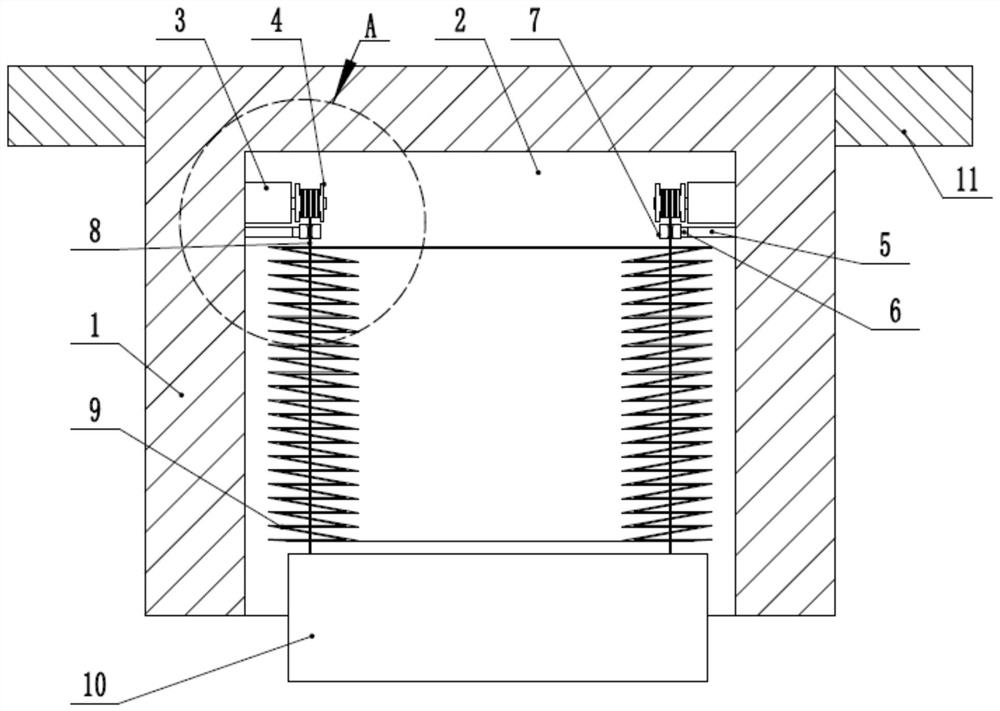

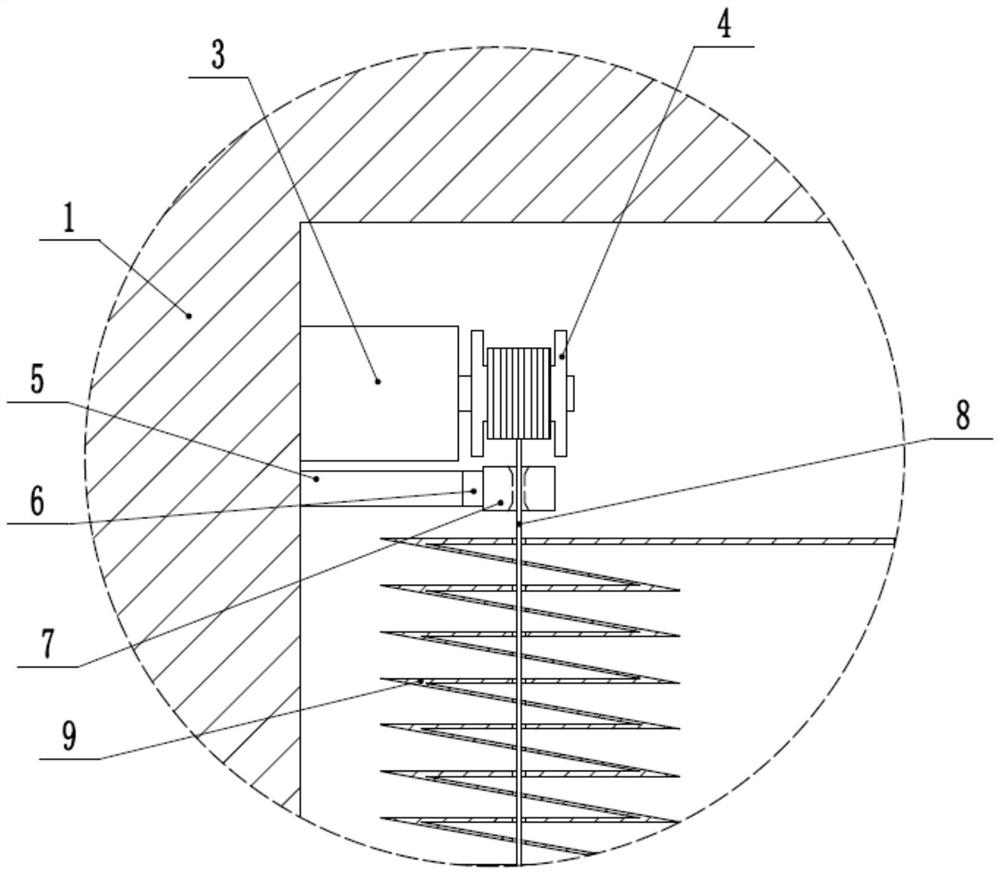

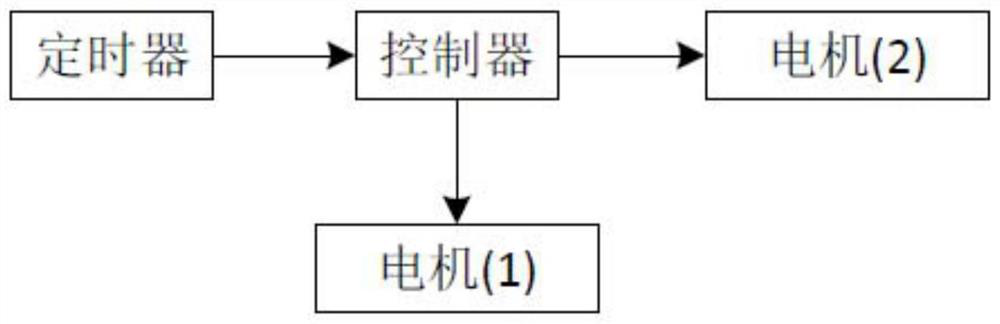

[0025] Ceiling-mounted intelligent audio main unit that is easy to disassemble, such as figure 1 and figure 2 As shown: including the body 10 and the mounting base 1 for mounting on the wall, the body 10 is installed on the mounting base 1, the mounting base 1 is welded with a fixing plate 11, and the fixing plate 11 is threaded with screws to be fixed to the wall. Specifically, a groove 2 is opened on the mounting base 1, and the body 10 is accommodated in the groove 2. A telescopic assembly in a retracted state is connected between the body 10 and the top wall of the groove 2. The telescopic assembly includes a bellows 9. There are several winding ropes 8 running through the pipe 9, and two winding ropes 8 are provided. The winding ropes 8 can be made of existing steel wires to improve the strength. The winding ropes 8 run through the side wall of the bellows 9. Over, one end of the winding rope 8 is bonded on the power mechanism, and the other end of the winding rope 8 is...

Embodiment 2

[0032] The difference with Embodiment 1 is that, if Figure 4 and Figure 5 As shown, the mounting seat 1 is cylindrical, and the mounting seat 1 is welded with a collar 15 positioned at the outer circumference of the body 10, and a number of fixing seats 12 are welded between the collar 15 and the mounting seat 1. Four fixing seats 12 can be arranged to fix Infrared emitting tube 13 and infrared receiving tube 14 are installed respectively on the seat 12, and infrared emitting tube 13 and infrared receiving tube 14 are provided with two pairs, namely two infrared emitting tubes 13 and two infrared receiving tubes 14, one infrared emitting tube 13 and infrared receiving tube 14. An infrared receiving tube 14 is installed on the fixed seat 12 as a pair, and the fixed seat 12 is located on the reflection line of a pair of infrared emitting tubes 13 and the infrared receiving tube 14, and the infrared receiving tube 14 feeds back to the controller when receiving the reflected inf...

Embodiment 3

[0035] The difference from Embodiment 1 is that it also includes a human body sensor, a voice collector and a vibration sensor. The human body sensor detects a human body signal within a preset time period and sends it to the controller. Pause to control the reverse start of the motor when the human body signal is received, the vibration sensor is installed on the bellows 9, the vibration sensor detects the vibration intensity value of the bellows 9 and sends it to the controller, and the controller controls after the vibration intensity value is greater than the preset intensity. The motor starts in reverse, and the preset strength is set according to the strength when pulling the body 10 for cleaning. The timing length can be set according to the time required for cleaning, such as ten minutes; the voice collector is used to collect the voice information of the owner and send it to the controller. When the human body signal is received within the preset difference time before...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com