Brake cylinder comprising a locking device for mechanical brake force locking

A technology of locking device and brake cylinder, which is applied in the direction of brake transmission device, operating mechanism of railway vehicle brake, brake, etc., and can solve problems such as high emergency release force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

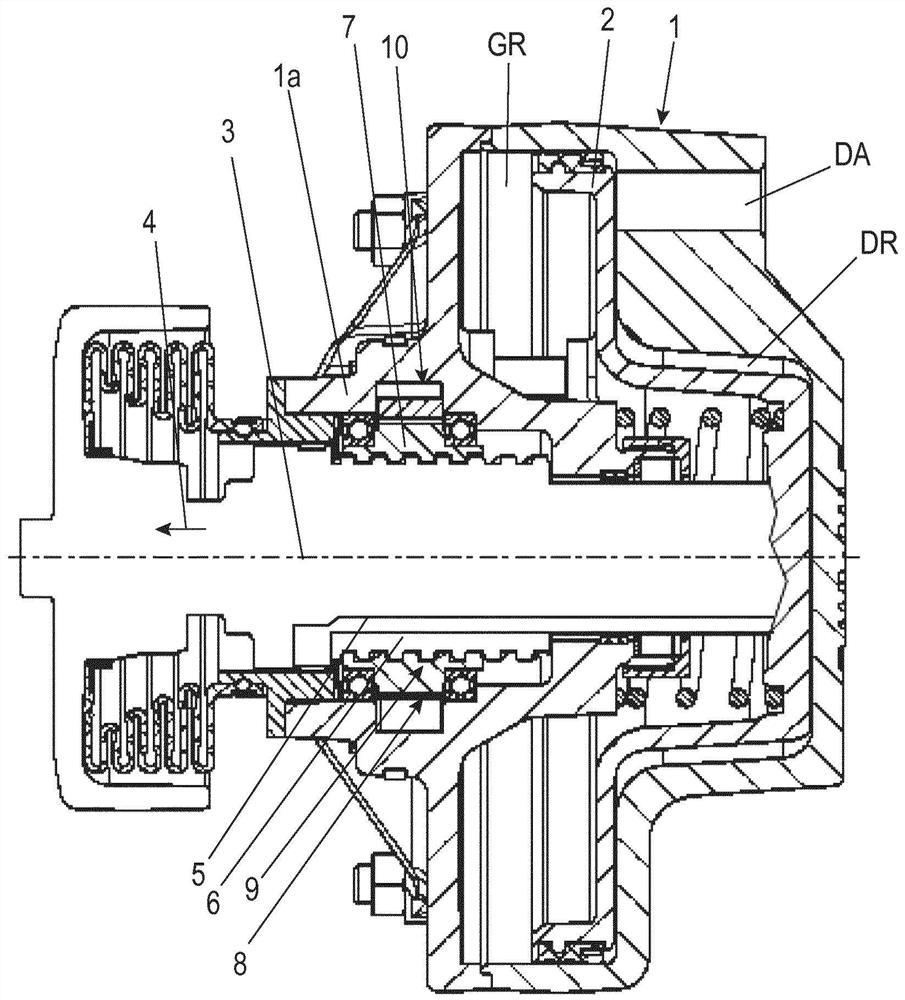

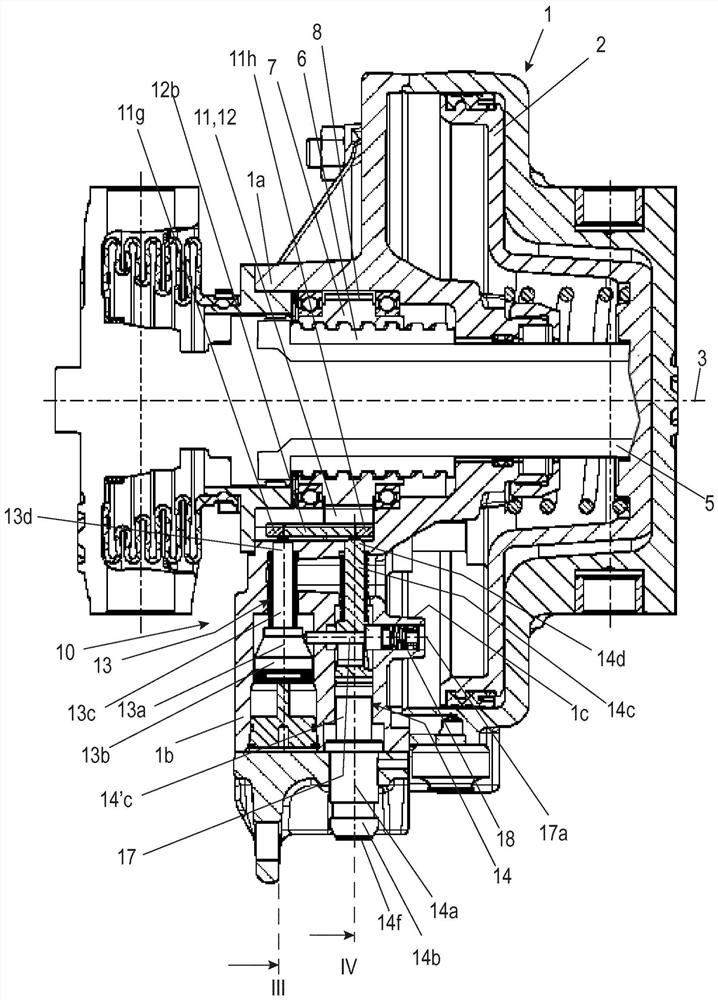

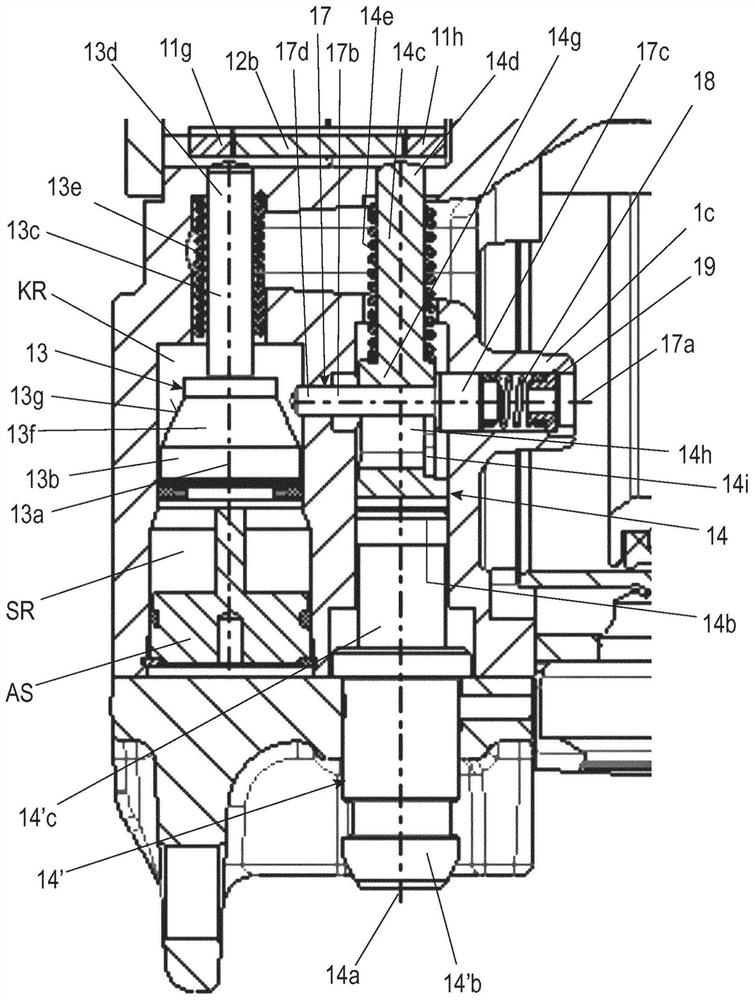

[0035] figure 1 A schematic longitudinal section through a first exemplary embodiment of a brake cylinder 1 according to the invention with a locking device 10 is shown. figure 2 The diagram in shows the basis of figure 1 A longitudinal section of the brake cylinder 1 rotated 90° around the piston axis 3 . Figure 2a Shown in rest position based on figure 2 An enlarged sectional view of the arrangement of the control piston 13 and the emergency release tappet 14 of the locking device 10 of the embodiment of FIG. Figure 2b The arrangement of the control piston 13 and the emergency release tappet 14 in the release position of the emergency release tappet 14 is shown. Figure 2c The released position of the control piston is shown.

[0036] The brake cylinder 1 has a locking device 10 as a mechanical brake force locking device and is provided for use in a rail vehicle.

[0037] The generally known construction and function of brake cylinder 1 will not be described in de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com