Torque reduction amount determination method and device, vehicle and storage medium

A determination method and torque reduction technology, which is applied to control devices, vehicle components, electric vehicles, etc., can solve the problems of unable to meet the needs of shift quality, consume manpower and material resources, and poor accuracy, so as to improve the efficiency and accuracy of determination, Realize the effect of automatic determination, saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

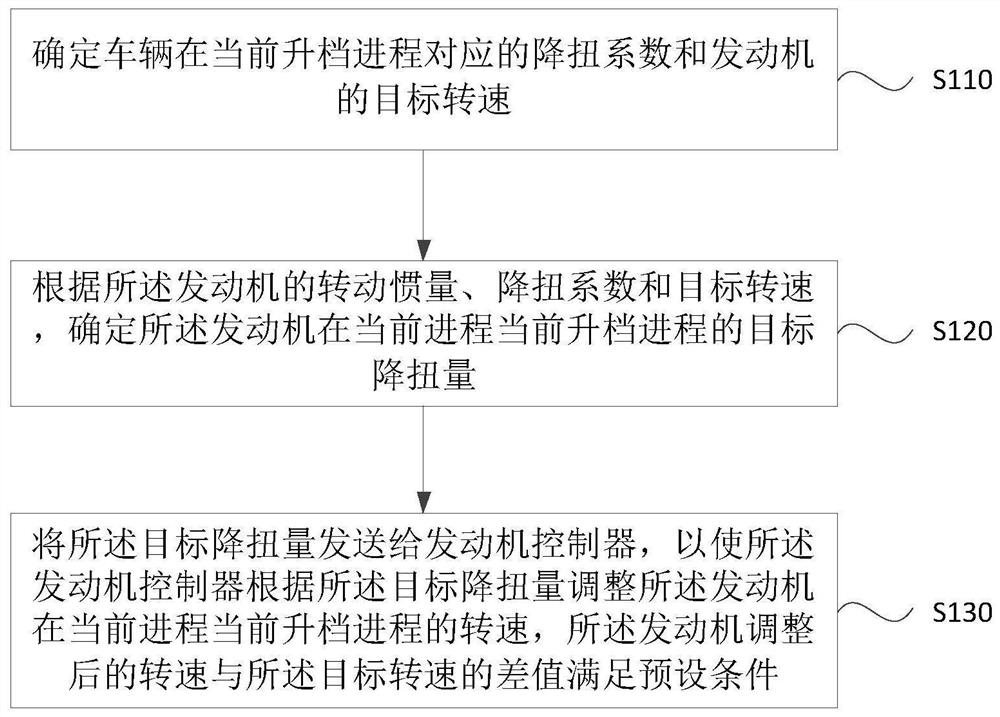

[0029] figure 1 It is a flow chart of a method for determining the amount of torque reduction provided by Embodiment 1 of the present invention. This embodiment is applicable to the situation of determining the amount of torque reduction of the engine when the vehicle performs a power upshift. The method can be determined by the amount of torque reduction The device may be implemented by means of software and / or hardware, and may be integrated in a vehicle, which may be a vehicle with an automatic control function. refer to figure 1 , the method may include the following steps:

[0030] S110. Determine the torque reduction coefficient and the target engine speed corresponding to the current upshift process of the vehicle.

[0031] Wherein, the current upshift process is any process between the start of the vehicle upshift and the end of the upshift. It can be understood that when a vehicle with automatic control function calculates the parameters required for automatic cont...

Embodiment 2

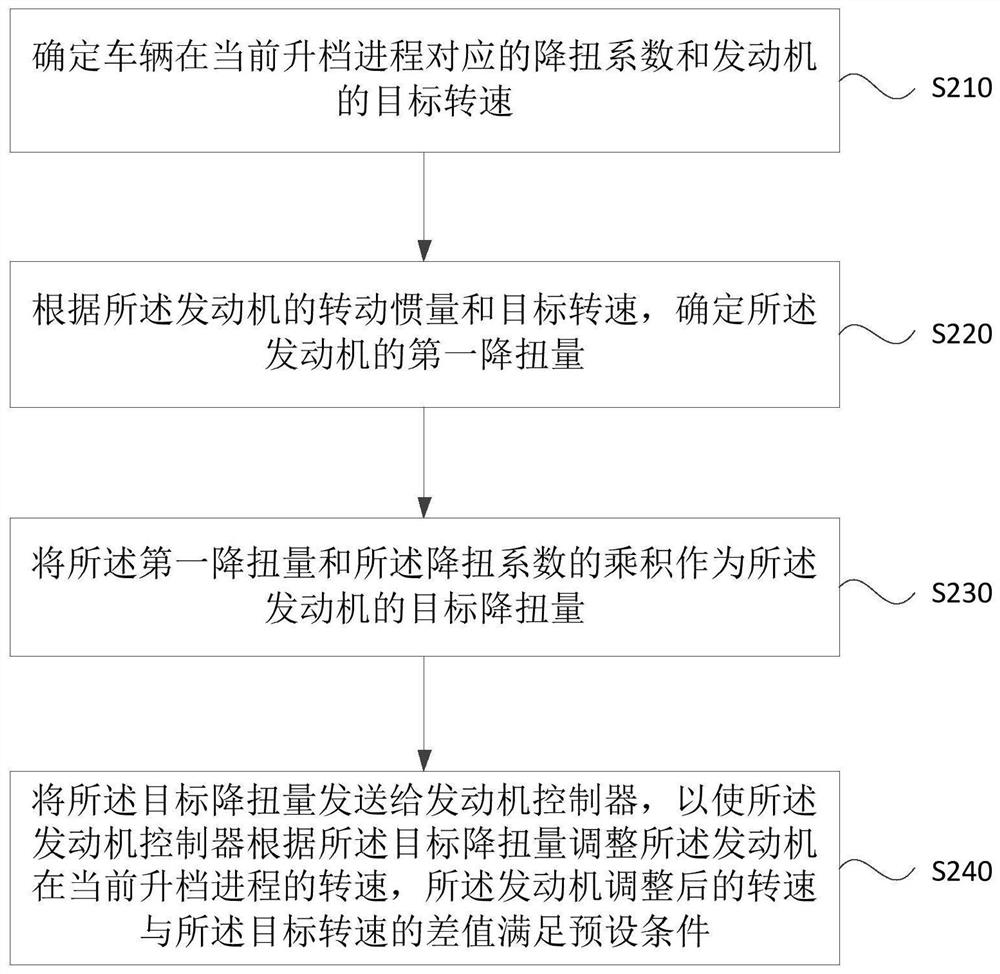

[0039] figure 2 It is a flow chart of a method for determining torque reduction provided by Embodiment 2 of the present invention. This embodiment is optimized on the basis of the above-mentioned embodiments. Refer to figure 2 , the method may include the following steps:

[0040] S210. Determine the torque reduction coefficient and the target engine speed corresponding to the current upshift process of the vehicle.

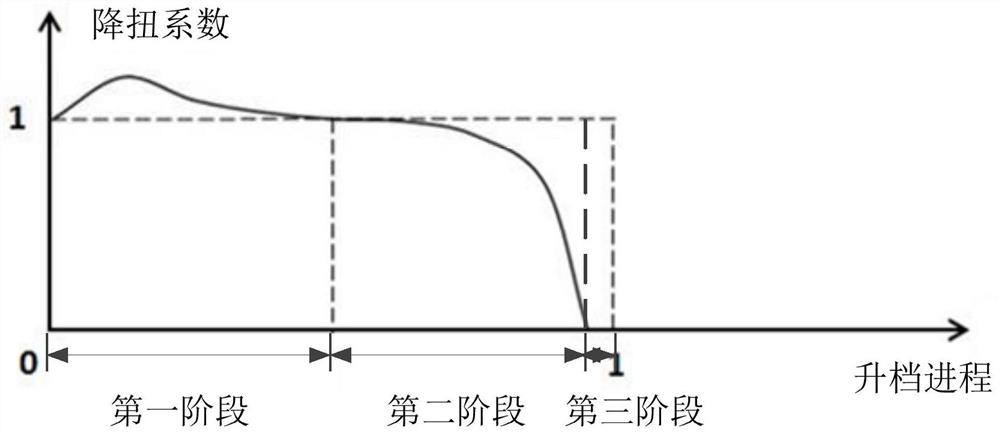

[0041] Optionally, the torque reduction coefficient corresponding to the current upshift process can be determined as follows:

[0042] determining the opening degree of the accelerator pedal in the current upshift process of the vehicle;

[0043] Determine the torque reduction coefficient corresponding to the current upshift process according to the upshift information, the current upshift process and the opening degree of the accelerator pedal, the upshift information includes the corresponding gears before and after the upshift of the vehicle bit informat...

Embodiment 3

[0061] Figure 5 A structural diagram of a device for determining the torque reduction provided by Embodiment 3 of the present invention, the device can implement the method for determining the torque reduction described in the above embodiment, refer to Figure 5 , the device can include:

[0062] Coefficient and rotational speed determination module 31, is used for determining the torque reduction coefficient corresponding to the current upshift process of the vehicle and the target rotational speed of the engine, and the current upshift process is any process between the start of the vehicle's upshift and the end of the upshift;

[0063] The target torque reduction determination module 32 is used to determine the target torque reduction of the engine in the current upshift process according to the moment of inertia of the engine, the torque reduction coefficient and the target speed;

[0064] The target torque reduction sending module 33 is configured to send the target to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com