Safety air bag assembly and automobile

An airbag and assembly technology, which is applied in vehicle safety arrangement, pedestrian/passenger safety arrangement, vehicle components, etc., can solve the problems of insufficient stability of the airbag and small area surrounded by the installation point of the airbag, so that it is not easy to burn out , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

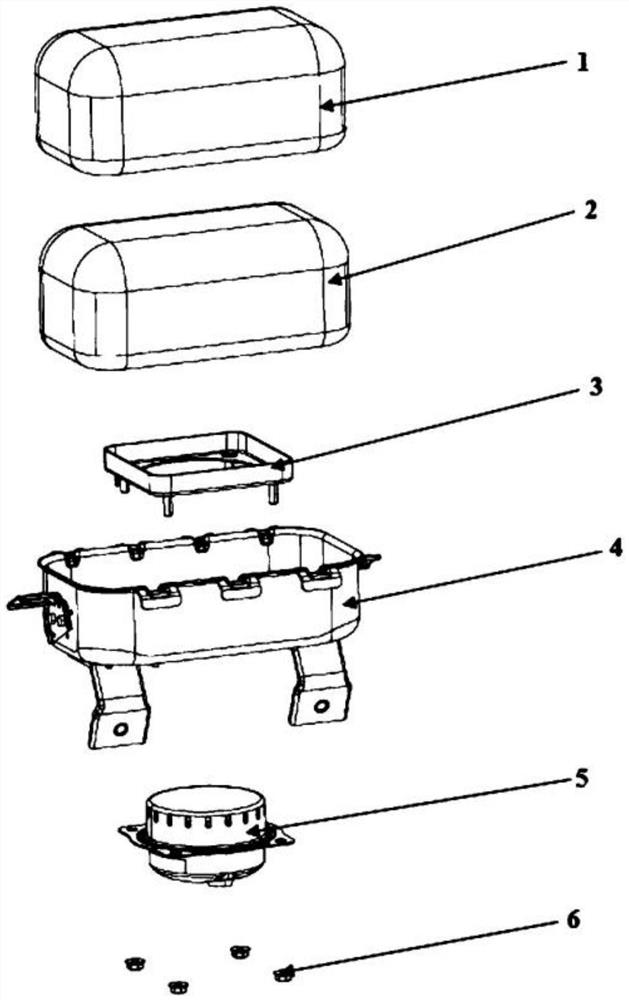

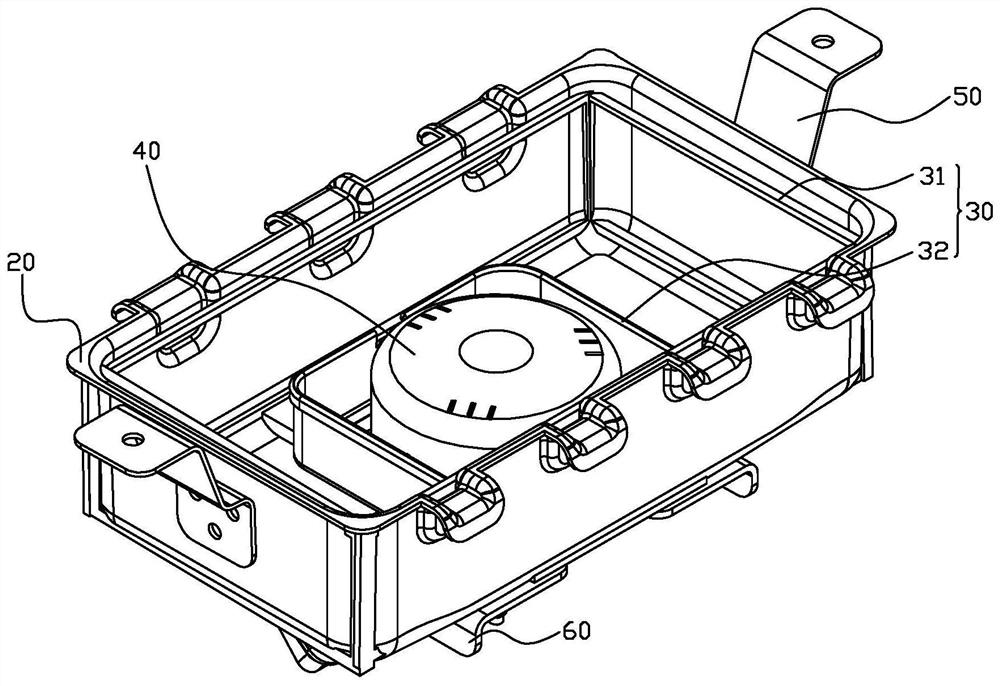

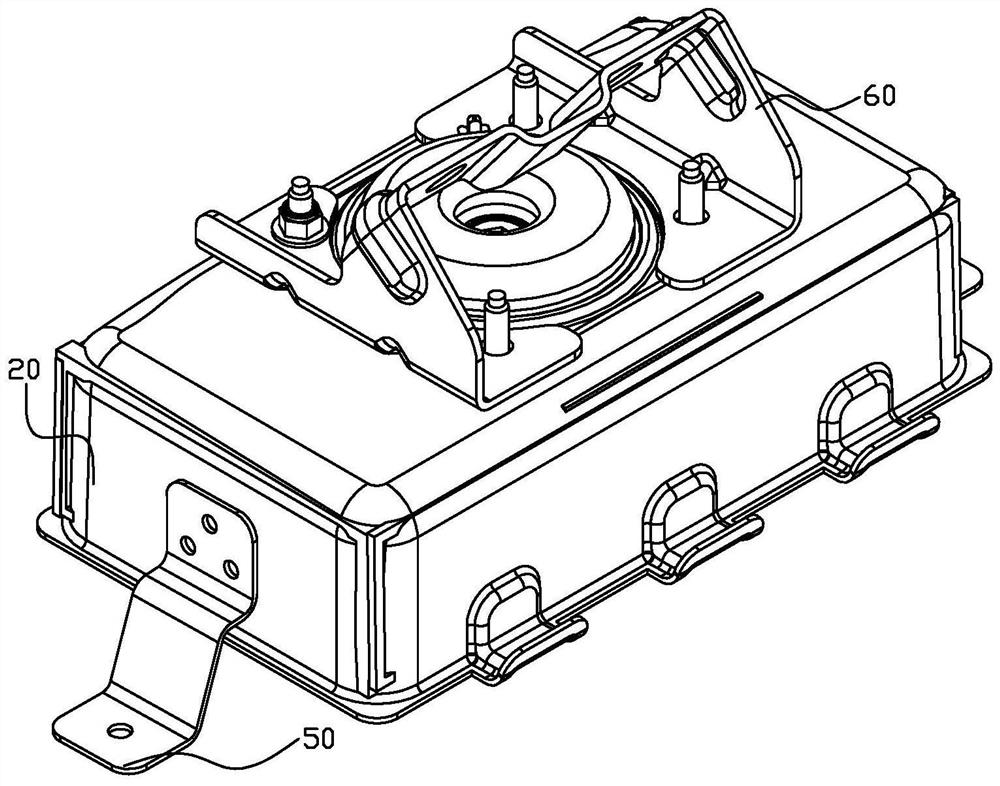

[0034] figure 2 It is a schematic diagram of the local structure of the airbag assembly in the first embodiment of the present invention, image 3 for figure 2 Schematic diagram of the structure from another angle, Figure 4 for figure 2 Partial sectional view in, Figure 5 for figure 2 Schematic diagram of the deployment of the middle airbag. Please combine Figure 2 to Figure 5 , the present embodiment provides an automobile airbag assembly, which specifically includes: a gas generator 40, which generates gas; an air bag 10, which expands due to the gas generated from the gas generator 40; an accommodation tank 20, where the air bag 10 is arranged In the air bag accommodating groove 20; Holding mechanism 30 is arranged in the air bag 10, and holding mechanism 30 comprises holding frame 31, and air bag 10 is arranged between holding frame 31 and air bag accommodating groove 20, and holding frame 31 makes air bag 10 The outer wall is close to the inner wall of the a...

no. 2 example

[0041] Figure 7 It is a schematic diagram of the local structure of the airbag in the second embodiment of the present invention, Figure 8 for Figure 7 Schematic diagram of the local structure. Please combine Figure 7 and Figure 8, The difference between this embodiment and the first embodiment is that the holding frame 31 specifically includes a first side plate 311, a second side plate 312, a third side plate 313 and a fourth side plate 314, the first side plate 311 and the second side plate 311 The side panels 312 are arranged oppositely, and the third side panel 313 and the fourth side panel 314 are arranged oppositely. The first side plate 311 , the second side plate 312 , the third side plate 313 and the fourth side plate 314 are all solid plates. The gas generator 40 generates a large amount of gas after receiving the current signal, and the gas generated by the gas generator 40 encounters the guide groove 32 in the center of the holding mechanism 30, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com