Friction wheel type material acceleration device with self-adaptive distance adjustment function

A technology of self-adaptive adjustment and acceleration device, which is applied in the direction of launching device, planter parts, transportation and packaging, etc., and can solve the problems of non-adaptive adjustment, non-adjustable friction wheel, non-adaptive adjustment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

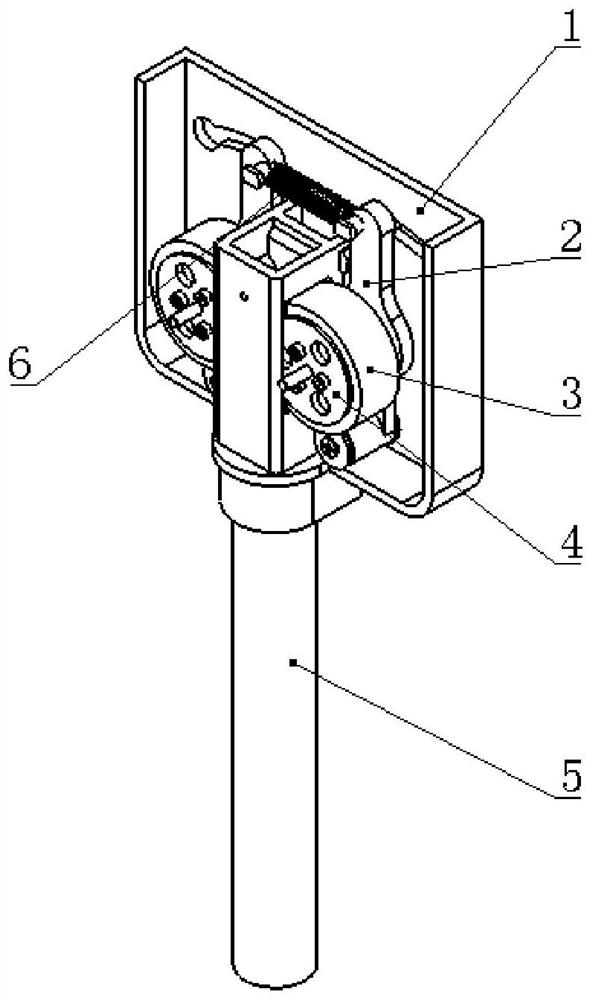

[0044] The embodiment of the present invention is mainly applied to the cultivation of crops, and accelerating the coated seeds to penetrate into the soil is of great significance to the cultivation of crops such as rice. Such as figure 1 Shown is a schematic diagram of the overall structure of the embodiment of the present invention, the embodiment of the present invention is a friction wheel type material acceleration device with self-adaptive adjustment of spacing, including:

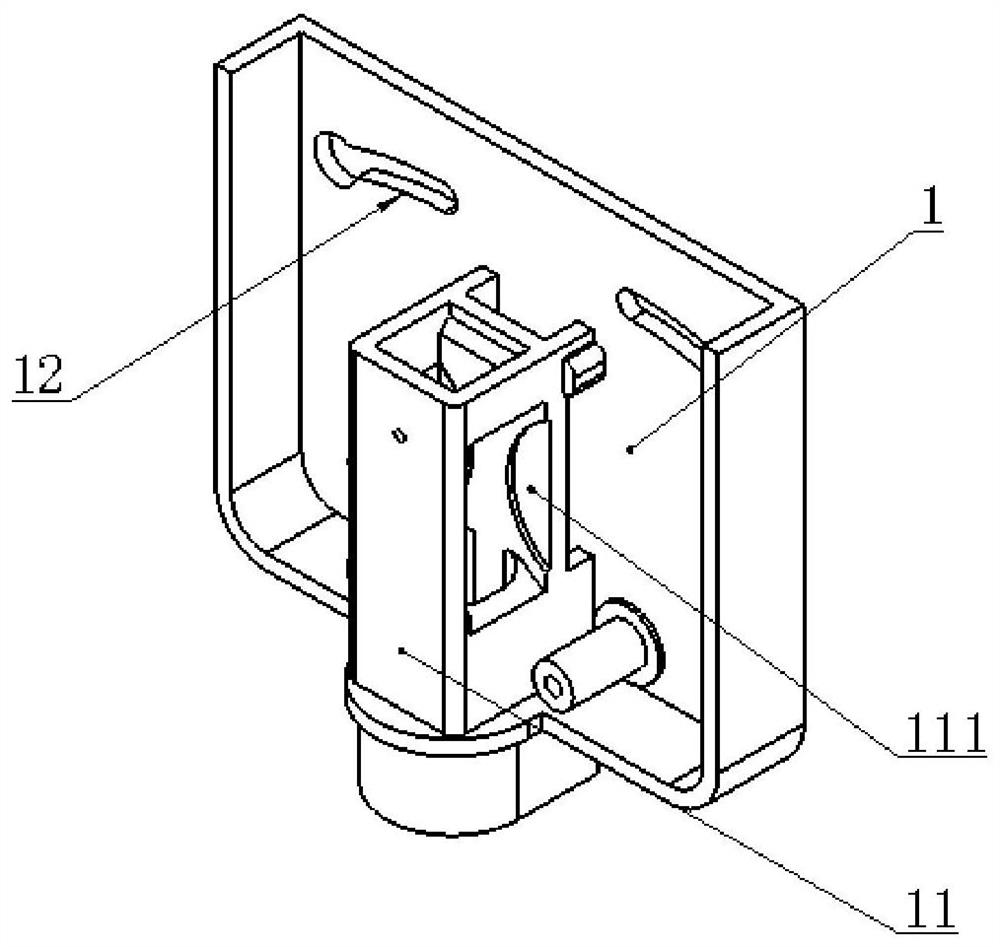

[0045] Mounting plate 1, such as figure 2 The mounting plate 1 in this embodiment is shown as a rectangular structure;

[0046] Acceleration tube 11, such as figure 2 The accelerating tube 11 shown is divided into an upper part of the accelerating tube and a lower part of the accelerating tube. The upper part of the accelerating tube is a square tube with a square section and a nozzle. The upper part of the accelerating tube is fixedly installed at the central axis of the mounting plate 1. There...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com