Drawer type storage rack

A drawer-type, shelf technology, applied in display shelves, display hangers, display tables, etc., can solve the problem of low work efficiency and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

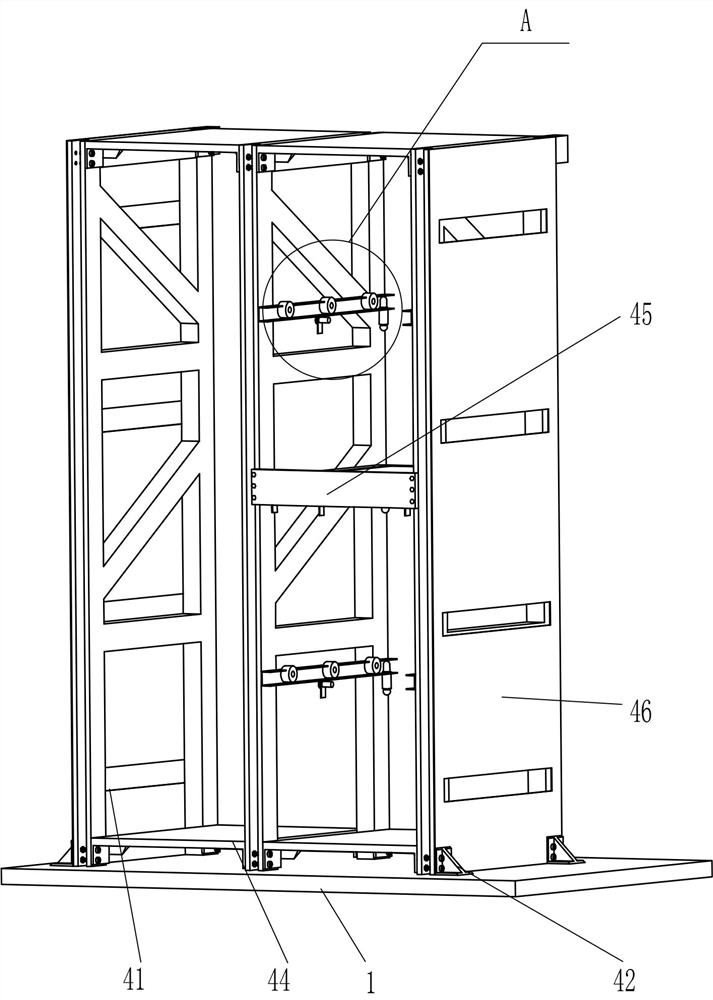

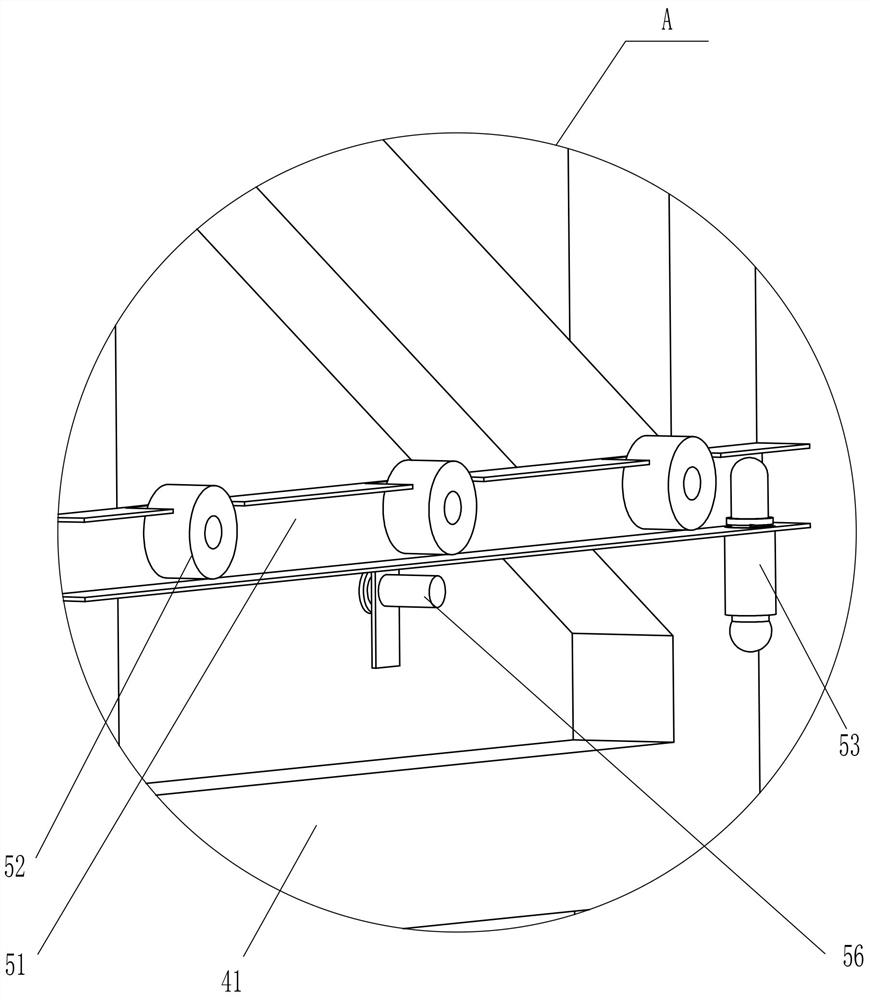

[0027] A drawer type storage shelf, such as figure 1 , figure 2 , image 3 and Image 6 As shown, it includes a bottom plate 1, a support column 2, a motor base 3, a load-bearing mechanism 4, and a push-pull mechanism 5. The support column 2 is symmetrically fixed on the left side of the top of the bottom plate 1, and the motor base 3 is fixed on the right side of the top of the bottom plate 1. The bottom plate 1 is provided with a load-bearing mechanism 4, and the load-bearing mechanism 4 is provided with a push-pull mechanism 5.

[0028] The load-bearing mechanism 4 includes a load-bearing steel frame 41, a supporting triangular block 42, a connecting plate 44, a limit block 45 and a light-shielding plate 46, and three load-bearing steel frames 41 are fixedly connected at intervals on the left side of the top of the bottom plate 1, and the leftmost load-bearing steel frame The lower part of the left side of 41 and the left side of the top of the base plate 1 are fixedly ...

Embodiment 2

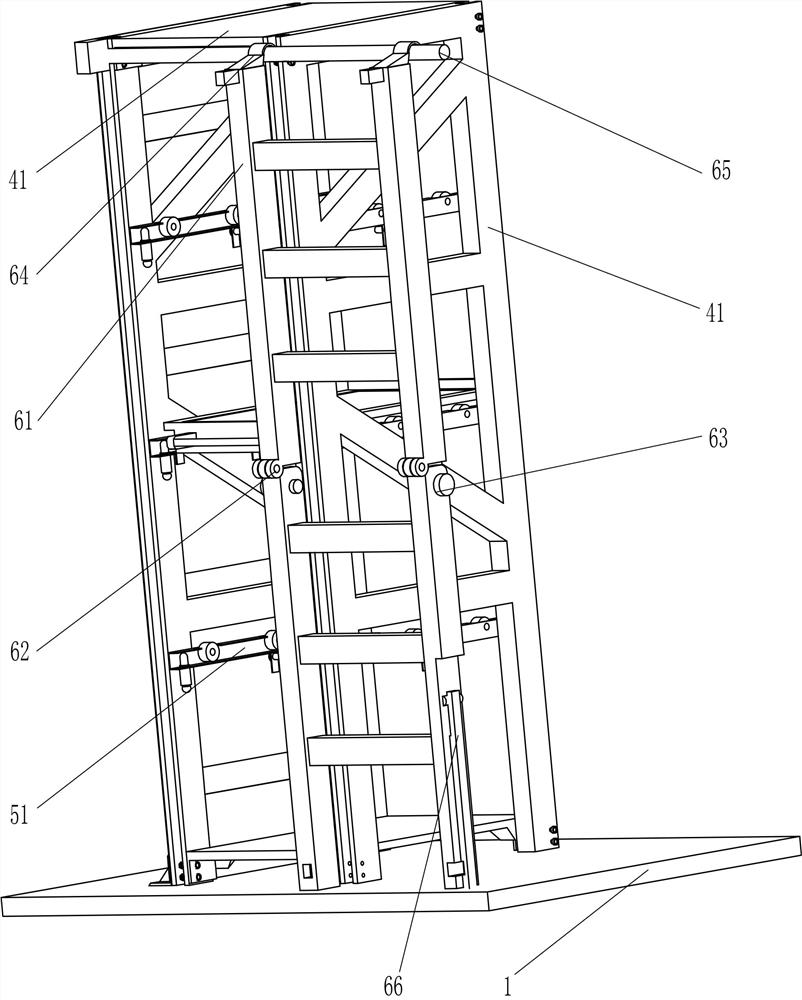

[0034] On the basis of Example 1, such as figure 1 , Figure 4 and Figure 5 As shown, a climbing mechanism 6 is also included, and the climbing mechanism 6 includes a folding ladder frame 61, an extended ladder frame 62, a fixed bolt 63, a support buckle 64, a force rod 65 and a folding support leg 66, three load-bearing steel A force-bearing rod 65 is fixedly connected between the front side of the upper part of the frame 41, and the left and right sides of the force-bearing rod 65 are symmetrically hinged with a support buckle 64, and a folding ladder frame 61 is fixedly connected between the left and right side support buckles 64, and the folding ladder frame The articulated lower part of 61 is provided with an extended ladder frame 62, and the symmetrical sliding type between the lower part of the folding ladder frame 61 and the upper part of the extended ladder frame 62 is provided with a fixed latch 63, and the symmetrical hinged type of the lower part of the extended ...

Embodiment 3

[0039] On the basis of embodiment 1 and embodiment 2, such as figure 1 , Image 6 and Figure 7 As shown, a blocking mechanism 8 is also included, and the blocking mechanism 8 includes a baffle slide rail 81, a safety baffle 82 and a rubber buckle 83, and the upper parts of the inner sides of the two load-bearing steel frames 41 on the left side are fixedly connected with the baffle slide rails. 81, a safety baffle 82 is slidably provided between the baffle slide rails 81 on the left and right sides, and the symmetrical hinged type at the bottom of the safety baffle 82 is provided with a rubber buckle 83, and the rubber buckle 83 cooperates with the grip bar 55.

[0040] Also comprise cushioning mechanism 9, cushioning mechanism 9 comprises storage plate 91, movable axle sleeve 92 and cushioning spring 93, and four movable axle sleeves 92 are affixed evenly spaced in the bottom of load-bearing pumping plate 54, and movable axle sleeve 92 inner bottoms are affixed with dampin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com